Steel is undeniably one of the best manufacturing materials out there. But it’s safe to say that the number of grades and types to choose from makes it hard to find the perfect option. If toughness and resistance to things like corrosion and wear are all important, you’ll probably come across 52100 steel as an option, and for good reason. Thanks to its composition (which is high in carbon), you get all these properties and more. Here’s what to know about it, how it’s made, and what pros and cons you can expect from using it.

What Is 52100 Steel?

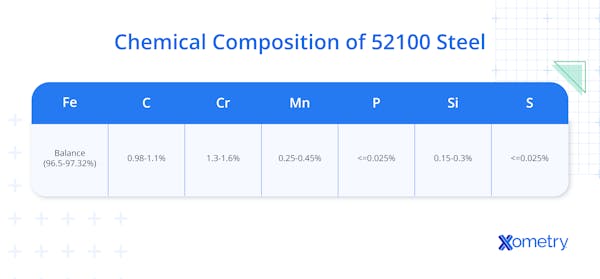

While it has many names, 52100 steel is chromium-alloy steel with a high carbon content that gets praised for its ability to put up with taxing situations—whether that’s corrosive environments or an expectation to go through serious wear and use. Composition-wise, it has 0.98-1.10% carbon, 1.30-1.60% chromium, 0.15-0.30% silicon, 0.25-0.45% manganese, and trace amounts of other elements like phosphorus (<= 0.025%) and sulfur (<= 0.025%).

Naming Equivalents

To stay on top of the steel type you’re using across the world, these are the global name equivalents for 52100.

| Country/Governing Body | Equivalent Grade/Name |

|---|---|

Country/Governing Body USA | Equivalent Grade/Name $52,199 |

Country/Governing Body China (GB) | Equivalent Grade/Name Cr2; GCr15 |

Country/Governing Body EU (EN) | Equivalent Grade/Name 102Cr6 (1.2067) |

Country/Governing Body France (AFNOR) | Equivalent Grade/Name 100Cr6; 100Cr6RR |

Country/Governing Body Germany (DIN, WNr) | Equivalent Grade/Name 100Cr6 |

Country/Governing Body Japan (JIS) | Equivalent Grade/Name SUJ2 |

Country/Governing Body England (BS) | Equivalent Grade/Name 534A99; 535A99 |

Country/Governing Body Italy (UNI) | Equivalent Grade/Name 100Cr6 |

Country/Governing Body Sweden (SS) | Equivalent Grade/Name 2258 |

Country/Governing Body Poland (PN) | Equivalent Grade/Name LH15 |

Country/Governing Body Russia (GOST) | Equivalent Grade/Name KH; ShKh15 |

52100 Steel Global Name Equivalents Table Credit: Steel Numbers

How It’s Made

Making 52100 steel is very similar to concocting other types of steel. It’s just a matter of getting the composition right. Here are the steps of the process you can usually expect:

- First, all the raw materials (like carbon, iron, and chromium) in their specific quantities are added to an electric arc or induction furnace.

- Once it’s molten, it’s refined with argon oxygen decarburization or vacuum degassing, as this ditches any impurities that can impact the end product.

- Then, the molten steel will be cast into the intended shape, whether that’s sheets, billets, ingots, or something different.

- After casting it will be heated again, then shaped and processed in order to lock in those top qualities and ensure the grain structure is how it should be.

- Then, annealing takes place, which reduces internal stresses and refines the steel’s microstructure.

- Hot working will usually be followed by heat treatments to harden and temper the steel.

- Now, it’s ready for finishing, like grinding, polishing, and machining.

| Property | Metric | Imperial |

|---|---|---|

Property Machinability (Spheroidized, cold drawn, and annealed. Based on AISI 1212 steel as a reference with a 100% machinability) | Metric 40% | Imperial 40% |

Property Knoop Hardness | Metric 875 | Imperial 875 |

Property Bulk Modulus | Metric 140 GPa | Imperial 20300 ksi |

Property Density | Metric 7.81 g/cm3 | Imperial 0.282 lb/in³ |

Property Fracture Toughness | Metric 15.4-18.7 MPa•m½ | Imperial 14.0 - 17.0 ksi•in½ |

Property Poisson's Ratio | Metric 0.27–0.30 | Imperial 0.27–0.30 |

Property Modulus of Elasticity | Metric 190–210 GPa | Imperial 27557–30458 ksi |

Property Shear Modulus | Metric 80 GPa | Imperial 11600 ksi |

Property Applications | Metric Anti-friction bearings, punches, taps, dies, mill rolls, bolts, screws, fasteners, and automotive and aircraft components. | |

Property Machinability | Metric 40% | Imperial 40% |

Property Thermal expansion coefficient (@ 23-280°C/73.4- 36°F, annealed) | Metric 11.9 µm/m•°C | Imperial 6.61 µin/in•°F |

Property Thermal conductivity | Metric 46.6 W/m•K | Imperial 323 BTU•in/hr•ft²•°F |

Property Melting point | Metric 1424° C | Imperial 2595° F |

52100 Steel Properties and Characteristics Table Credit: Azo Materials

Heat Treating 52100 Steel

Heat treating 52100 steel helps improve the hardness of your material. For this kind specifically, you’ll likely be looking at a divorced eutectoid transformation (DET) anneal before you jump right into heat treating. Annealing it in this way involves getting the steel to 1460°F and leaving it for 30 minutes, then cooling it to 1260°F, followed by air cooling.

Then, you’ll austenitize the steel at 1500 to 1525°F for anywhere from 10 to 30 minutes. This is followed by oil quenching and tempering at a temperature between 300 and 500°F. Remember that higher austenitizing temperatures can lead to higher hardness, but using cryogenic processes can take this hardness even further.

Common Formats

Here is what you can expect when it comes to the shapes, formats, and finishes you can find 52100 steel in:

- Sheet: These are flat pieces of steel, and you can find them in numerous thicknesses and sizes, perfect for custom cuts.

- Bar: The format you need for things like bearings, gears, and other mechanical products. They’ve got excellent strength and are shaped like cylinders.

- Plate: These look like sheets but tend to be thicker, making them perfect for times when you need serious strength and durability.

- Hot Rolled: These bars are made by heating 52100 to high temperatures then rolling them into the shape you’re after.

- Annealed: This heat treatment gives steel better machinability and helps alleviate any internal stresses that crop up when it’s being made.

- Cold Drawn: These bars are pulled through a die, which gives them a better finish and much more accurate dimensions.

Pros and Cons of 52100

Here are some of the perks you can expect from 52100 steel:

- With tempering, heat treating, or quenching, you get a very hard steel.

- Because of the carbon content, it’s super resistant to wear.

- It’s also highly resistant to fatigue and can handle multiple loads and stresses without failing.

- Even in tough conditions, it will hang onto its shape.

- After heat treating, you’ll have a steel material that’s great for machining.

There are also some downsides to be aware of with this particular steel:

- It is corrosion-resistant, but not nearly as much as other types of stainless steel.

- Welding with 52100 can be tricky and requires specific preheating processes to do it successfully.

- This type of steel can be much more brittle than other types.

- It also tends to be a slightly more expensive steel compared to others.

- In its fully hardened state, it can be much more difficult to machine.

FAQs About 52100 Steel

What’s the difference between 52100 and other steels?

Steels all vary based on their composition and purpose, but 52100 is normally used for bearings that have high loads and friction. Other steels might be better for corrosion resistance or heat resistance, for instance. Two other examples that are often compared are D2 steel and S30V steel. The former is great for cutting tools, dies, and punches that are susceptible to heavy wear and tear and the latter is best for things like knife blades because it’s resistant to corrosion and durable.

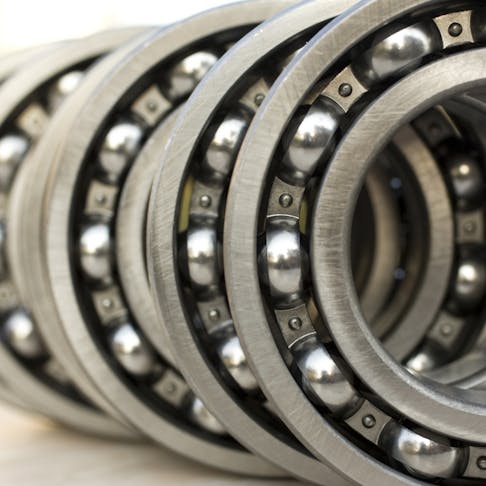

What is 52100 steel used for?

This kind of steel is made for putting up with heavy loads and a good dose of friction. That’s why 52100 is often used for bearings or components for machines, especially in the world of aerospace and automotive.

How Xometry Can Help

We offer many different services at Xometry that involve steels like 52100, including CNC machining, sheet metal fabrication, and stainless steel 3D printing—all of which you can get free quotes for.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.