Aluminum bronze is a strong and corrosion-resistant alloy used in many industries, including aeronautical and marine. In this article, we’ll look at what it’s made of, what exactly it’s used for, and all its pros and cons.

What is Aluminum Bronze?

Also known as "aluminum gold" or "gold bronze," thanks to its light gold hue, aluminum bronze is an alloy mainly made of copper and aluminum. It can contain anywhere from 88–92% copper and 4–14% aluminum, along with varying amounts of other alloying elements like silicon, nickel, iron, or manganese.

Adding aluminum to copper gives the alloy its strength by forming a hardy and protective aluminum oxide layer that sticks to the material’s surface. Alloys with high aluminum content can be as strong as medium-carbon steel, and much more corrosion-resistant, too. To make it even harder, a good post-processing treatment, like cold working stress, will do the trick.

Adding in small amounts of other alloying elements could give the material even more benefits. For example, iron could ramp up its mechanical strength, and nickel makes it more corrosion-resistant. These durable alloys are particularly handy for parts that have to withstand harsh conditions (think industrial engineering, aerospace, and marine).

What Is the History of Aluminum Bronze?

Scientists first started experimenting with the copper/aluminum combo in the mid-1800s but couldn’t get very far as the materials and production processes were very expensive and rather complex. In 1913, a French metallurgist, Pierre Durville, started making aluminum bronze billets by finding solutions to the oxide inclusion (impurities) and shrinkage problems with the tilting ladle method. This created much stronger alloys with greater corrosion resistance.

A short while later, another metallurgist and engineer, Charles H. Meigh, improved this technique and created nickel aluminum bronze with some help from the French Admiralty. There was no denying this alloy’s benefits, but the material was hard to cast so the public wasn’t very keen to try it out.

It was only after World War II that aluminum bronze really started taking off thanks to the industrial boom, which included the expansion of the offshore oil and marine sectors, and the need for strong and corrosion-resistant propellers for much larger and faster ships and submarines. Since then, use of aluminum bronze has only increased, and it’s used to make many things like marine hardware, pump and valve components, bearings, bushings, and gears.

What Is the Other Term for Aluminum Bronze?

Aluminum bronze is also known as "aluminum gold" or "gold bronze." Known for its light gold hue, this alloy has good casting qualities but is difficult to forge. Because of its distinct set of qualities, aluminum bronze — which includes strength and resistance to corrosion — finds use in a wide range of sectors, making it a viable material for certain engineering applications.

Is Aluminum Bronze the Same as Brass?

While both aluminum bronze and brass are copper alloys, aluminum bronze has aluminum, tin, iron, and nickel in addition to copper. Instead of tin or aluminum, the major alloying element in brass is zinc. Aluminum bronze is stronger and more resilient than brass. It has a tensile strength of 780 MPa, compared to brass’s 200 to 500 MPa.

What Is Aluminum Bronze Made Of?

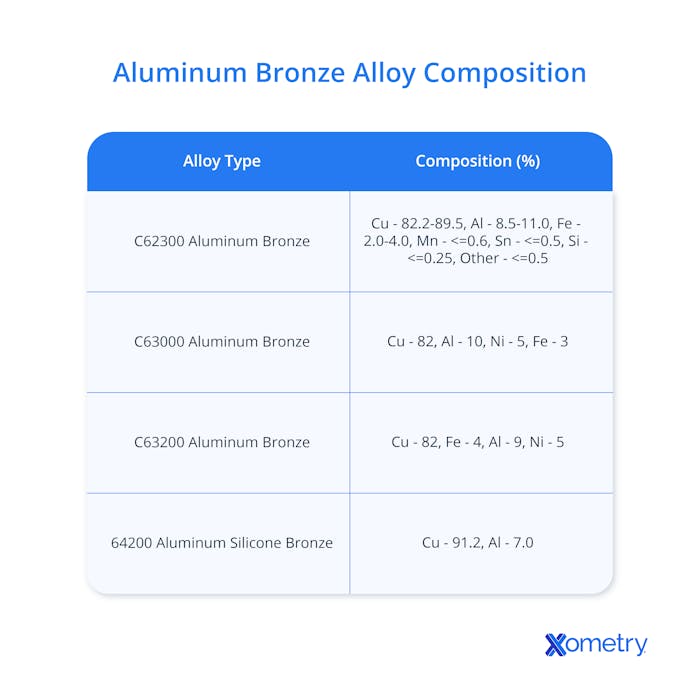

Over the years, hundreds of different aluminum-bronze alloy types have been developed, each with its own specific combination of materials which makes them ideal for different uses. Each type has its own Unified Numbering System (UNS) designation. In the table below, you’ll find examples of some of the most common types of aluminum bronze alloys and their compositions.

Aluminum bronze alloy composition.

How Is Aluminum Bronze Made?

There are many manufacturing processes that can be used with aluminum bronze, including welding, and laser cutting. Before we go into those, let’s look at how to actually make this alloy from scratch using the classic bronze casting process.

First things first, you’ll need all the proper protective gear and make sure your working area is clean and well-ventilated. You’ll also need the appropriate manufacturing equipment like an industrial-grade crucible or forge (although, for small-scale forging, you can use a blowtorch). The aluminum and copper should be weighed in a 9:1 ratio before being put in the crucible. The metals then need to be melted together at 1,038 °C and stirred with a graphite rod until they are thoroughly mixed.

After pouring the mixture into a mold, it should be left to cool and firm for 20 minutes, before being carefully removed (it will obviously still be very hot). For a shiny finish, dunk it in water to quench it. Other casting methods used to make aluminum bronze include centrifugal, continuous, investment, and sand casting processes.

After casting, the alloy can be made into many different items using various manufacturing methods. These include machining (milling, turning, drilling, grinding, and CNC machining), heat treatment (annealing, quenching, tempering), surface treatment (polishing, coating, plating), forging, extrusion, cold working, powder metallurgy, die casting, and joining via various welding methods.

Laser cutting is a great way to cut aluminum bronze. Compared to other more traditional cutting methods, laser cutting has a minimal heat-affected zone (HAZ), reducing the risk of the material becoming distorted or losing any of its valuable properties. It’s also versatile and can cut alloys of various thicknesses.

Aluminum bronze is also easy to weld. It usually needs no preheating (except for particularly thick sections), but a thorough clean before and after each pass will help prevent porosity. A MIG welder is a great option because it creates strong bonds and keeps all the alloy’s good properties.

What Are the Characteristics of Aluminum Bronze?

Aluminum bronze is known for its excellent wear resistance, which is why it’s commonly used in products that need to last a long time in harsh environments. The alloy is non-sparking, making it the perfect choice for making tools for chemical and petroleum industries, mine maintenance, explosive handling, and gas equipment.

Thanks to the quick-forming aluminum oxide protective coating, aluminum bronzes are a common choice in the chemical, atmospheric, and marine sectors. Their impressive corrosion resistance makes them a common go-to. Even if the coatings do get scratched or damaged, they can be fixed almost immediately.

This alloy can be both cold and hot worked. Aluminum bronzes with less than 8–10% of aluminum in them are used for cold working to easily shape things like tube sheets, flats, and wires. Alloys with 8–10% aluminum start to have more strength and hardness, so they’ll need hot working procedures and they can certainly withstand the high temperatures involved during shaping and forming. The best temperature to hot work these alloys is 1300°F and higher.

What Is the Color of Aluminum Bronze?

In terms of what it looks like, as we’ve already briefly covered, aluminum usually has a warm, golden hue, with coppery tones—but not always. Its final color will depend on its exact content, i.e., more copper will lend the alloy a deeper orange color. Overall, this alloy is one of the most attractive, and can even be polished to make it reflective and even prettier. Below is an image of the different shades that aluminum bronze can come in. As you’ll note, some don’t even look like bronze!

Different shades of aluminum bronze.

Coin made of aluminum bronze.

Image Credit: Shutterstock.com/CL Shebley

What Are the Different Types of Aluminum Bronzes?

Aluminum bronze alloys fall into four categories: (1) high alloyed two-phase aluminum bronzes, (2) low nickel aluminum bronze, (3) silicon aluminum bronzes, and (4) manganese aluminum bronzes. You’ll find more information on these different types in the table below.

| Type | Composition | Specifications |

|---|---|---|

Type High alloyed two-phase aluminum bronzes | Composition 8–11% aluminum, often with added iron or nickel | Specifications

|

Type Low nickel aluminum bronze | Composition Less than 8% aluminum | Specifications

|

Type Silicon-aluminum bronzes | Composition Up to 2% silicon and 6% aluminum | Specifications

|

Type Manganese-aluminum bronzes | Composition 8–9% aluminum, 13% manganese | Specifications

|

Types of Aluminum Bronze

| Property | Description |

|---|---|

Property Strength | Description Possesses high tensile strength compared to low-alloy steel |

Property Machinability | Description Poses challenges in machining due to high strength, abrasiveness, thermal conductivity, copper content, and poor chip formation, affecting tool durability. |

Property Weldability | Description Usually requires no preheating, except for thick sections. Thorough cleaning before and after each pass prevents porosity. These alloys are valuable as weld-depositing surfacing materials for wear, corrosion, and sparking resistance. |

Property Corrosion Resistance | Description Resists corrosion in various environments, particularly in seawater and under acidic conditions. |

Property Color | Description Typically has a distinctive golden color, offering aesthetic appeal in various applications. |

Property Antimicrobial | Description Depending on the specific composition, some aluminum bronzes may exhibit biocompatibility, making them suitable for certain medical applications such as dental alloy. |

Table 2: Properties of Aluminum Bronze

What Are the Chemical Properties of Aluminum Bronze?

Just to recap, the chemical properties of aluminum bronze are its composition of 4–14% aluminum by weight, with the rest being copper along with small amounts of other alloying materials like iron, nickel, manganese, silicon, and zinc. It has low oxidation rates even in higher temperatures, and it’s highly corrosion resistant, thanks to the alumina layer that it forms. It’s less reactive than aluminum or copper materials alone, and although it can oxidize over time, the rates are low. It’s also heat resistant and stays stable at higher temps.

| Chemical Property | Description |

|---|---|

Chemical Property Composition | Description Contains 4-14% aluminum by weight, with the remainder being copper, along with small quantities of iron, nickel, manganese, silicon, and zinc. |

Chemical Property Oxidation Resistance | Description Experiences low rates of oxidation even at elevated temperatures. |

Chemical Property Corrosion Resistance | Description The corrosion resistance is attributed to the formation of a thin, tough surface layer of alumina (aluminum oxide), acting as a barrier to corrosion. |

Table 3: Chemical Properties of Aluminum Bronze

| Physical Property | Description |

|---|---|

Physical Property Young's Modulus | Description 110 GPa |

Physical Property Density | Description 7.45 g/cm³ at 20 °C |

Physical Property Melting Point (solidus) | Description 1030 °C |

Physical Property Thermal Conductivity | Description 59 W/mK |

Physical Property Brinell Hardness | Description 170-177 BHN |

Physical Property Ultimate Tensile Strength | Description 550-900 MPa |

Table 4: Physical Properties of Aluminum Bronze

Is It a Good Idea To Cut Aluminum Bronze Using a Laser Cutter?

Yes, a laser cutter is a good way to cut aluminum bronze. Before laser cutting, metals — especially those that reflect a lot — might require an anti-reflective coating. CO2 lasers might not be the best option; fiber lasers often provide superior outcomes. The process provides precision, minimal material loss, and limited thermal stress, ensuring a clean and efficient cut.

Is Welding Possible with Aluminum Bronze?

Yes, it is possible to weld aluminum bronze. MIG welding, utilizing an aluminum bronze core wire and pure argon gas, is a suitable technique. This method ensures a strong bond and maintains the alloy's properties such as high strength.

What Are the Applications of Aluminum Bronze?

Aluminum bronze alloy is used in many industries for everything from engine components and marine hardware to guitar strings. The alloy's exact chemical composition will determine its manufacturing and environmental compatibility, however.

1. Guitar Strings

Guitar strings made of aluminum bronze are strong, have bright tones, and are resistant to corrosion over time. This combination of properties adds to the quality of a musical performance, making aluminum bronze a popular choice for strings.

2. Engine Components

Aluminum bronze offers excellent strength, resistance to wear, and effective heat dissipation, all key features for long-lasting engine components. Aluminum bronze is used in automotive piston pins due to its high strength and wear resistance. These properties help withstand the repetitive stress and friction in the engine, ensuring durability and longevity in such critical components.

3. Marine Hardware

Aluminum bronze makes dependable hardware for maritime applications because it resists corrosion from saltwater. It is a favored option for a variety of marine components due to its durability and dependability.

4. Aircraft Components

With its combination of strength, resistance to corrosion, and heat stability, aluminum bronze holds a prominent position in the manufacture of aircraft components. Aluminum bronze is used in aviation components such as bushings and bearings. For these applications, its great strength and resistance to corrosion are essential, offering dependable support in important parts where tough environmental conditions, longevity, and low maintenance requirements are crucial.

5. Nonoxidizing Acids

Designed for environments with nonoxidizing acids, aluminum bronze resists corrosion, maintaining structural integrity in acidic conditions. Aluminum bronze finds application in chemical processing equipment handling nonoxidizing acids, like hydrochloric acid. Its corrosion resistance surpasses that of many materials, ensuring prolonged equipment life in aggressive acidic environments, where standard alloys might succumb to corrosion.

6. Valve Components

Actuated Butterfly Valves made of aluminum bronze offer clear benefits in corrosive conditions. Longer service life is largely dependent on their superior corrosion resistance, especially in the chemical processing, offshore, and maritime industries. These valves guarantee operating reliability with minimal maintenance requirements. Furthermore, they provide accurate flow control that boosts fluid handling system efficiency, which makes them essential parts for important uses where corrosion and saltwater resistance are required.

7. Industrial Process Fluids

Aluminum bronze plays a vital role in equipment that handles industrial process fluids. It is resistant to corrosion from many industrial fluids. Parts made from aluminum bronze significantly extend the lifespan of equipment, guaranteeing reliable and consistent performance over timeAluminum bronze plays a vital role in equipment that handles industrial process fluids such as acids and alkalis. It is resistant to corrosion from many industrial fluids. Key components of chemical processing plant pumps, valves, and fittings are made of aluminum bronze. The durability and efficiency of vital equipment in industrial environments are improved by its resistance to corrosion in acids and alkalis.

Xometry can machine aluminum bronze - it can be custom machined to all shapes and sizes but it's typically used when making bearings or gear componentsGreg PaulsenDirector, Applications Engineering

Is Aluminum Bronze Used in Sand Casting?

Yes, aluminum bronze is used in sand casting. Because of its strength and resistance to corrosion, aluminum bronze is sometimes used for sand casting at the foundry. This guarantees the creation of castings that are robust and resistant to corrosion.

What Are the Advantages of Aluminum Bronze?

- Strength and durability: Aluminum bronze is very hard and has a compressive and high tensile strength, meaning it will wear out and/or break at a much slower rate than other materials. Depending on the exact alloy composition and heat treatment, its strength can be compared to that of some low alloy steels, and even some stainless steels. It can withstand both wear and abrasion, making it extremely durable, too.

- Rust, corrosion, oxidation, tarnish resistance: Aluminum bronze doesn’t rust (the term “rust” refers to the corrosion of iron and iron-based alloys). It has a high level of corrosion resistance, even when exposed to seawater and acids, thanks to its ability to form a tough aluminum oxide (alumina) protective layer. Even in higher temperatures, its oxidation rates are low. It’s also the most tarnish-resistant of all the copper alloys, remaining entirely unaffected when faced with atmospheric corrosion.

- Reactivity: Aluminum bronze is generally less reactive than pure metals on their own, like aluminum or copper, making it more compatible with other metals and materials for many different uses.

- Low friction: Aluminum bronze has a friction coefficient of about 0.18 when unlubricated, generating much less friction between itself and other materials compared to other materials, including tool steel (coefficient of 1.11). This helps it slide smoothly on other surfaces and reduces the level of wear and heat generated during operation.

- Heat resistant and non-sparking: This alloy will generally stay stable even at high temperatures. It’s also non-sparking making it ideal for use in environments where sparks could be a safety hazard and ignite flammable gases, vapors, or dusts. This is a particularly useful perk to have in industries like oil and gas, chemical, and mining.

- Antimicrobial: Depending on its specific makeup, some aluminum bronze alloys are suitable for medical applications (i.e., dental alloy), thanks to their biocompatibility.

- Variety and aesthetic appeal: The sheer variety of aluminum bronze alloys offers a lot of manufacturing flexibility and possibilities. The different and attractive color available also gives you many aesthetic options.

What Are the Disadvantages of Aluminum Bronze?

- Hard to machine/forge: Aluminum bronze has excellent strength, abrasiveness, thermal conductivity, and copper content, but its poor chip formation and hardness (which is a perk in many instances) make machining quite challenging. Also, despite its good casting qualities, it’s difficult to forge.

- High maintenance: This diva of an alloy needs quite particular and specific care to keep up its appearance. It needs to be cleaned with gentle soap and water solution, and then dried with a soft cloth.

- High cost: Aluminum bronze is most often more expensive than other similar materials because of its pricey ingredients (like tin, aluminum, and silicon). The perks these additions offer, however, often justify the increased cost.

- Limited availability: This alloy is not as widely available as other options, and you could find yourself struggling to source it, especially if you need lots of it.

Frequently Asked Questions About Aluminum Bronze

Does Aluminum Bronze Rust?

No, aluminum bronze does not rust. Rusting specifically refers to the corrosion of iron-based alloys, while aluminum bronze, composed of aluminum, copper, and sometimes other elements, may corrode but does not undergo rusting as iron does.

Is Aluminum Bronze Better Than Bronze?

Yes, aluminum bronze is generally considered better than traditional bronze, which typically consists of copper and tin. Aluminum bronze exhibits enhanced mechanical properties, including higher yield strength, making it suitable for applications demanding increased durability and strength. The presence of aluminum in the alloy contributes to these improved characteristics, and its lattice mismatch with copper can lead to the formation of specific phases, allowing for heat treatment to achieve the desired properties.

Does Aluminum Bronze Tarnish?

No, aluminum bronze is highly tarnish-resistant, making it the most tarnish-resistant among copper alloys. Its appearance remains unaffected even when exposed to atmospheric corrosion, highlighting its durability and resistance to tarnishing.

Is Aluminum Bronze As Strong as Steel?

Yes, aluminum bronze can exhibit strength comparable to low alloy steel and certain stainless steels, depending on alloy compositions and heat treatment. However, it's essential to note that some steel grades, particularly high-alloy and tool steel, generally possess greater strength than aluminum bronze.

Summary

We hope we covered everything you wanted to know about aluminum bronze, but if there’s anything we haven’t answered about this useful alloy, please reach out to a Xometry representative. We also offer a wide range of manufacturing services, so feel free to visit our website to learn more or request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.