There are a few key equations you can’t escape in the world of manufacturing and engineering, and elongation at break is certainly one. Knowing what this valuable principle calculates can help you select the right materials—and be the difference between a successful and functional product. If you want to know all about this equation, how it works, and why it’s good to know it, keep on reading.

What is Elongation at Break?

This measurement is used to figure out how long a material can stretch before it snaps, breaks, or fractures (that’s why it’s also called the “fracture strain”). The value itself shows the change between a material’s starting length and just how much it has stretched. It’s also a great value for understanding how much materials (like plastics, metals, or textiles) can deform before they’re unsafe or unusable, which can affect things as simple as their looks and as important as their safety. It gives you a great idea of how much fatigue a material can handle, which in turn leads to better selections so that the products you make won’t break unexpectedly.

How Does Elongation at Break Work?

Elongation at break works in many materials such as metals. The primary mechanism of plastic deformation in metals is slip movement. It takes place when the applied stress exceeds the critically resolved shear stress and causes atoms to slide over one another within the crystal lattice. Dislocations move along tightly packed planes and directions known as slip systems to cause this process. On the other hand, twinning takes over as the primary mechanism of plastic deformation in situations where slip is not an option.

In twinning, local atoms rearrange as mirror images of one another across a twinning plane as a result of an orientational change in the atoms. Twin planes and twin directions are defined planes and directions in crystallography where twinning occurs. Twinning is advantageous when there are fewer slip systems present because it enables planes to develop more slip. Accordingly, depending on the structure and available slip systems, twinning as well as slip both contribute to plastic deformation in metals.

What Is the Importance of Elongation at Break?

Elongation at break is important in assessing a material's capacity to plastically deform in a safe way, avoiding brittle failure. It is critical in applications for materials like rubber and plastic where the material will be stretched repeatedly or subjected to impacts.

For instance, in the automotive sector, elongation is a hugely important parameter for assessing the reliability and dependability of vehicle components. The fatigue limit stress is a top priority in the component designs because it allows for controlled failure through plastic deformation prior to final failure. For these parts, a high tensile elongation value is typically preferred, because it denotes a high degree of ductility and flexibility. It helps prevent failure under difficult circumstances. Elongation at fracture is also crucial in making packaging materials like protective plastic packaging. To guarantee that the products they contain are safeguarded during shipping and handling, these materials must be able to stretch and flex without breaking.

What Is the Formula for Elongation at Break?

There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. It’s pretty simple once you know how, but it involves a few different measurements:

Elongation at Break = (Final Length - Original Length) / Original Length x 100%

How To Calculate Elongation at Break?

Here are the steps you can take to figure out a material’s elongation when it fractures:

- First, measure the original length of your material before you start testing it

- Using one of the standard methods out there, complete a tensile test

- When the material gets to its breaking point (or fracturing fracture), take the measurements for the final length

- With those measurements you can fill out your equation to get the exact percentage

An example equation using aluminum could look something like this:

- Measure the original length of your piece of aluminum (we’ll use 50 mm as an example)

- Then do your tensile test. Once the aluminum snaps, measure its length now (say it fractured at a length of 75 mm)

- To find the change in length, you would calculate 75 mm - 50 mm = 25 mm.

- You can then complete the elongation at break equation, which would look like this:

Elongation at break = (change in length / original length) x 100%

Elongation at break = (25 mm / 50 mm) x 100%

Elongation at break = 50%

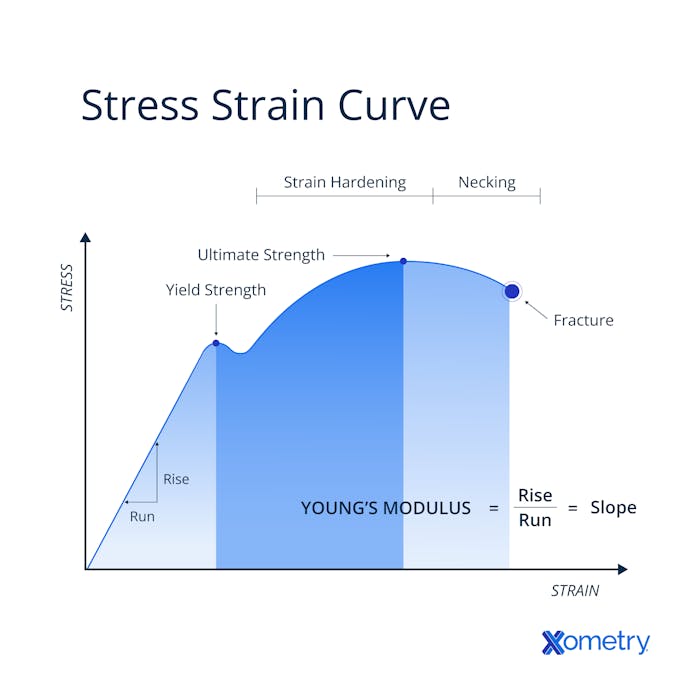

The image below is a visual representation of the stress strain curve and how elongation at break would be deciphered on a graph:

What Is the Unit Used To Express Elongation at Break?

Elongation at break is a unitless quantity that is normally expressed as a percentage. Elongation is expressed as a percentage because it describes the increase in the length of the material relative to its initial length at the point of failure in tension. The ductility or stretchability of various materials can be easily compared using this elongation metric.

How Is Elongation at Break Typically Measured?

Elongation is measured as part of the data collected during a tensile test. Tensile tests are conducted on universal testing machines (UTS). The tests are conducted using standard test methods such as ASTM E8. A test specimen of one of several standard sizes and shapes is made of the material to be tested. An extensometer is attached to the test sample to acquire the length change data. The test continues until the sample breaks, with the UTS continuously recording the strain reading from the extensometer as increasing tensile stress is applied by the machine.

What Kinds of Materials Are Typically Tested for Elongation at Break?

There are numerous materials you can run through a tensile test and get their fracture strain values. These tend to be the most common:

1. Steel

Different steel types will have slightly different properties, which will also change their elongation at break point, but you’ll typically find it range between 10% and 20%.

2. Textiles

The measurement is important in textiles as it can let you know when the fabric of a car seat or industrial fabric will break. Textiles are vastly different, of course, but as a few examples, you’ll find cotton has a 4–8% range, wool is usually between 24% and 45%, and polyester has an impressive value of 50% or higher.

3. Metals and Metal Alloys

Depending on how a metal is made and processed, it can react in a completely different way to a similar metal that may not have been cold forged or that underwent a different process. That’s why it’s important to test metals for their elongation at break values, too. It would take a long time to go through all types, but for context, an aluminum alloy usually has a fracture strain of 17% whereas pure copper will have one of 60%.

4. Polymers

All kinds of polymers get tested in this way, from squeaky polystyrene to shiny PVC, and their ranges are about as varied as the types of plastic and polymers out there. Knowing their values gives a good idea of when these materials will deform and not be able to bounce back and when they’ll break and lose all function. As a few examples, PVC normally has a wide range of 25–58%, but an even wider range comes from polystyrene, which can be anywhere from 1% to 79%. Intrigued? Teflon can have a fracture strain between 40-650%, and polyethylene has one between 300-900%.

5. Rubber Materials

As one of the stretchier options, natural rubber in its purest form can stretch up to 700% before it breaks. Synthetic rubbers (or fluoroelastomers) reach their point at about 300%.

What Are Some Factors That Can Affect Elongation at Break Values?

It’ll depend on the specific characteristics of material, but here are a few factors that take a toll on the elongation at break value of materials.

- Temperature: If the conditions feature warmer temperatures, you’ll tend to get higher readings of elongation at break percentages.

- Velocity during testing: If tensile strain is slowly introduced, you’ll find a material can sometimes stretch longer before breaking.

- Composite fillers: Composite materials with more fillers in them tend to have a lower value.

- Fiber orientation: Depending on how the fibers of a material are woven or aligned can also affect the point at which it snaps.

How Does the Chemical Composition of A Material Affect Its Elongation at Break?

A material's elongation at break can be significantly influenced by its chemical makeup. For example, the presence of stiffening fillers or crosslinking agents can reduce the elongation at break of thermoplastics. The presence of plasticizers or softening agents can increase a material’s flexibility.

What Are Some Common Testing Standards for Measuring Elongation at Break?

There are a handful of standardized tests you can lean on for finding elongation values for multiple materials, which their names indicate:

- ISO 527-½ - Plastics: Determination of Tensile Properties

- ASTM D882 - Standard Test Method for the Tensile Properties of Thin Plastic Sheeting

- ISO 37:2017 - Rubber, Vulcanized, or Thermoplastic - Determination of Tensile Stress-Strain Properties

- ASTM D638 - Standard Test Method for Tensile Properties of Plastics

How Does Elongation at Break Relate to Tensile Strength?

Tensile strength evaluates a material's capacity to withstand stretching forces before breaking, whereas elongation at break evaluates a material's ability to plastically deform before fracturing. Materials with lower tensile strengths typically have a higher elongation at break values.

How Does Elongation at Break Relate to Yield Strength?

Although both yield strength and elongation at break are mechanical properties of a material, they measure different things. The yield strength of a material is the stress at which it begins to deform plastically under tension, whereas the elongation at break indicates how much total deformation occurs before the material breaks. High-yield strength materials typically have a low elongation at break, and vice versa. This is due to the fact that materials with high-yield strengths typically have fewer atomically mobile dislocations and/or fewer slip systems for dislocations to move on. Dislocation pinning usually results in a rise in strength and a fall in ductility. On the other hand, materials with low yield strengths are usually more ductile and can withstand more deformation before breaking.

How Is Elongation at Break Used in 3D Printing?

Engineers designing parts to be 3D printed take into account the elongation at break of the various candidate materials in order to select the best one for a given application. To create sturdy, printed objects that can withstand the stresses they will encounter in use, it is imperative to have a thorough understanding of a material’s ductility.

In FDM (Fused Deposition Modeling) 3D printing, elongation at break is affected by the orientation of the printed part. FDM prints are anisotropic, which means that they have various physical characteristics in various directions. FDM parts consequently have a different elongation at break values depending on the direction of pulling. For instance, a part pulled perpendicular to the print layers will have a different elongation at break than a part pulled parallel to the print layers.

How Can Elongation at Break Optimize 3D Product Design?

Elongation at break can optimize 3D product design in the following ways:

- It enables more design flexibility and the production of intricate geometrics without compromising structural integrity.

- It helps the material to withstand impact better. This is a result of enhanced ductility.

- Designers can reduce component thickness while maintaining structural integrity by utilizing more ductile materials. As a result, there is less material waste and weight, which can save money.

- When used in manufacturing processes like forging and rolling, materials with high ductility are simpler to form and shape. This can increase production efficiency, lower costs, and improve the quality of the finished product.

What Is the Elongation at Break of Different 3D Printing Materials?

Elongation at break is used a lot for testing how 3D-printed materials hold up under stretching and tensile stress. The value ranges of the most common printer materials are as follows:

- PLA: 5–10%

- ABS: 5–50%

- PETG: 58–110%

- TPU: 400–700%

- Nylon: 5–120%

Is Elongation at Break Significant When Choosing 3D Printing Materials

Yes, elongation at break is important to consider when selecting 3D printing materials because it shows how flexible the material is before it breaks. This is crucial for parts that might be stressed or impacted during use. The strength and longevity of the printed part can be guaranteed by selecting a material with the proper elongation at break.

What Are the Benefits of Elongation at Break?

The benefits of measuring and taking into account elongation at break include:

- Increased flexibility of the finished product

- Greater design freedom

- Enhanced durability and toughness

- Reduced risk of breakage

- Improved impact resistance

What Are the Limitations of Elongation at Break?

The limitations of depending on elongation at break for engineering design guidance are listed below:

- It may not provide a complete picture of a material's mechanical properties

- It may not accurately reflect a material's ability to withstand stress over time

- Environmental factors, such as temperature and humidity, can significantly impact test results

- It only measures the ability of a material to stretch before breaking, not its overall strength or durability

- Can vary depending on the sample size and testing conditions used

Does Elongation at Break Indicate How Much a Material Can Deform Before Breaking?

Yes, elongation at break shows the amount of deformation a material can withstand before failing. This is because the material's elongation at break, or ductility, is a measure of its capacity to withstand plastic deformation without breaking. A material that can plastically deform more before breaking is more ductile and has a higher elongation at break value.

Are Materials With Higher Elongation at Break Values Less Likely To Break Catastrophically?

Yes, materials with higher elongation at break values are typically less likely to break catastrophically. This is because they have a greater capacity for plastic deformation without fracture. This reduces the possibility of abrupt and total failure because these materials can stretch more before breaking when put under stress or strain. However, other factors, such as material strength and environmental circumstances, can also have an impact on how a material fractures.

How Xometry Can Help

We work with many different materials here at Xometry and once you’ve selected the one that’s right for you, we have services that cater to various metals, plastics, and composites. If you’re interested in metal extrusion, plastic injection molding, prototyping injection molding, or tube bending, you can get a free quote today.

Check out our Technical Datasheet Glossary to learn more about different material properties.

Copyright and Trademark Notices

- Teflon™ is a registered trademark and a brand name (Teflon ®) owned by Chemours (formally DuPont)

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.