Galvanized steel and galvannealed steel are very commonly used in many applications, but while they are similar, their distinct properties make them suited for different applications. Galvanized steel, with its zinc coating, is extremely durable and corrosion resistant, while galvannealed steel combines these properties with good paintability, weldability, and a visually pleasing surface finish due to its zinc-iron alloy coating.

In this article, we look at galvanized and galvannealed steels, what they are, where they are used, and what distinguishes them.

What Is Galvanized Steel?

Galvanized steel is – most commonly – low-carbon steel that has been coated with zinc. It combines the strength of steel with the corrosion resistance of zinc to produce a low-cost, versatile, and durable metal. There are numerous methods of galvanizing steel, but the most common method is hot-dip galvanizing. In this process, steel is dipped into molten zinc, which forms a coating on the steel. When the molten zinc coating is exposed to the atmosphere, it forms a thin layer of zinc oxide, which protects the steel from rust.

Steel components can also be galvanized after the fabrication of steel parts, with methods such as electroplating.

To learn more, see our article on the Galvanized Steel Process.

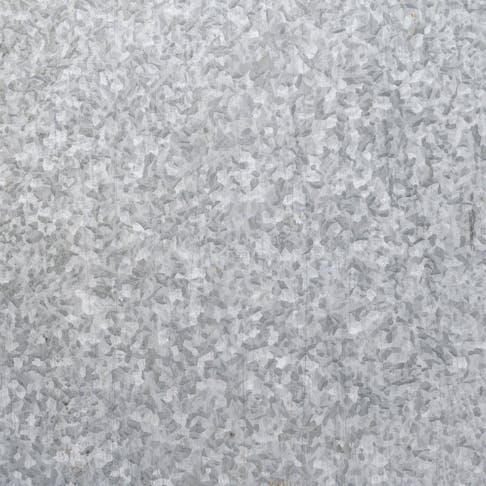

What Does Galvanized Steel Look Like?

Galvanized steel has a shiny, metallic silvery-gray appearance. It has a characteristic spangle pattern, which consists of small, shiny specks, and has a smooth texture. Figure 2 shows a galvanized steel plate with spangles:

Galvanized steel parts.

Image Credit: Shutterstock.com/T.Krit

What Is Galvanized Steel Used For?

Galvanized steel is commonly used in applications where strength and corrosion resistance are required. It is commonly used for structural elements such as beams, walkways, and roofing. Fasteners such as nuts and bolts are often made from galvanized steel, with the added corrosion resistance adding to their durability.

What Are Examples of Products Made From Galvanized Steel?

Several examples of galvanized steel in everyday use are listed below:

- Piping: Some piping is made of galvanized steel, due to its durability and corrosion resistance.

- Fasteners: Nuts, bolts, nails, and screws are commonly galvanized to add corrosion resistance. The galvanized steel coating protects fasteners from the elements, and is especially useful in outdoor applications

- Vehicles: The bodies of cars are usually made from galvanized steel to increase the corrosion resistance and lifespan of these vehicles. Bicycles are also sometimes made from galvanized for the same reason.

- Roofing Sheets: Commonly used due to their corrosion resistance.

- Structural Steel: Structural elements like beams are often made from galvanized steel due to their durability and rust resistance.

What Are the Advantages of Galvanized Steel?

Galvanized steel has several advantages over regular steel and other treated steels:

- Has high corrosion resistance due to the zinc coating. This makes it suitable for exposure to the elements, and even to applications with continuous water exposure.

- Compared to other treated steels, galvanized steel is relatively cheap to produce.

- Requires no additional maintenance or treatment over its lifetime.

- Combining the strength of steel with the rust resistance of zinc allows galvanized steel to last much longer than conventional steel.

What Are the Disadvantages of Galvanized Steels?

Despite all its advantages, galvanized steel also has some disadvantages compared to other treated steels:

- Contains zinc, which can leach into the environment releasing harmful toxins.

- The zinc coating on galvanized steel is prone to chipping and cracking, which exposes the underlying metal. This happens mostly in the manufacture of galvanized steel but can lessen the corrosion resistance of the entire piece, and lead to unsightly areas.

- Galvanizing causes the metal to become rigid, which makes it unsuitable when flexibility is required.

- The zinc coating increases the weight of the metal.

What Is Galvannealed Steel?

Galvannealed steel is steel that has been galvanized and then annealed. In the galvanizing step, a zinc coating is applied to the steel. After this, and while the zinc coating is still in its liquid form, the steel goes through the annealing process, which allows some of the iron to dissolve into the molten zinc. The iron-containing molten zinc then forms a zinc-iron alloy on the surface of the steel. This alloy is roughly 90% zinc and 10% iron. This zinc-iron alloy results in a harder, and more brittle coating than the zinc coating on galvanized steel.

To learn more, see our guide on Galvannealed Steel.

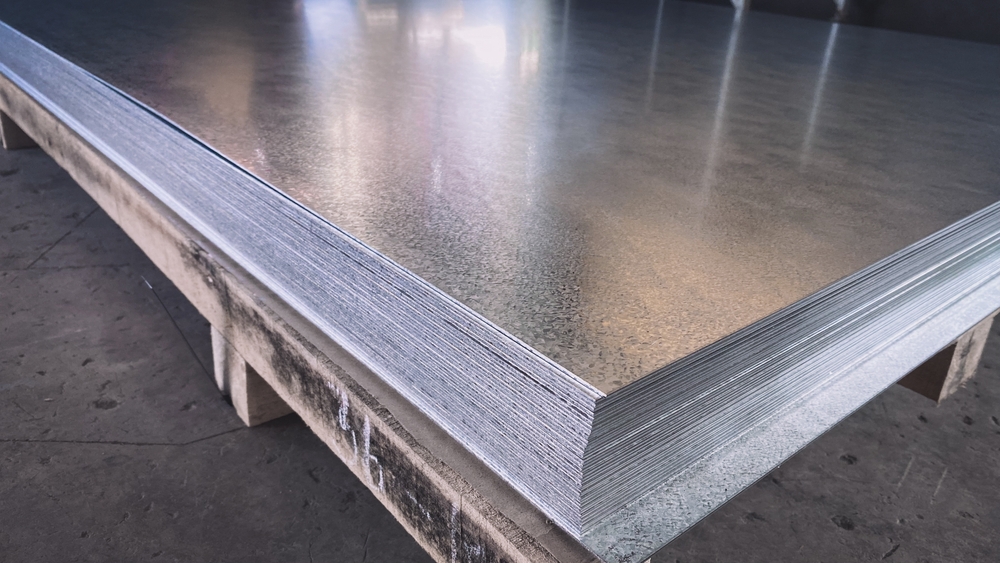

What Does Galvannealed Steel Look Like?

Galvannealed steel has a gray, matte finish that is generally considered to be visually appealing. The surface of galvannealed steel has a slight roughness compared to untreated steel or newly manufactured galvanized steel. The roughness depends on the details of the manufacturing process but is usually not very pronounced. The grain structure of galvannealed steel is visible under close inspection, but this graininess is very subtle. The galvanneal coating offers good paint adhesion, and so many galvannealed steel products will have some form of additional coating or paint. Figure 3 shows a galvannealed steel plate:

Galvannealed steel plate image

What Is Galvannealed Steel Used For?

Galvannealed steel, like galvanized, is commonly used in applications where added corrosion resistance and durability are needed. However, galvannealed steel is preferred in applications for which better formability, paintability, or weldability are needed than galvanized steel can provide.

Galvannealed steel is often used in architectural applications, where its aesthetically pleasing surface, along with its good paint adhesion make it an adequate and versatile choice. The automotive industry also uses galvannealed steel for vehicle body panels due to its formability and paintability.

What Are Examples of Products Made From Galvannealed Steel?

Galvannealed steel is found in many everyday objects, such as:

- Architectural Metals: It is commonly used in architectural applications due to its visually appealing surface finish.

- Automotive Panels: Automotive doors and panels are typically made from galvannealed steel. The high formability, corrosion resistance, and paintability make it an obvious choice.

- Household Appliances: Galvannealed is used in the production of household appliances, for structural components such as frames.

- Electrical Systems: Commonly used for making conduits, enclosures, and junction boxes, among other things.

What Are the Advantages of Galvannealed Steel?

The following list highlights some of the advantages of galvannealed steels:

- Has high ductility, meaning it can be bent easily into different shapes.

- Has high corrosion resistance due to the zinc-iron alloy coating.

- The presence of iron in the coating of galvannealed steel increases its hardness and resilience. This helps galvannealed steel be more resistant to chipping and scratching.

- Compared to galvanized steel, galvannealed steel has much better weldability, due to the presence of iron in the coating.

- The surface roughness of galvannealed steel increases paint adhesion, making it possible to get a good paint finish.

What Are the Disadvantages of Galvannealed Steel?

Galvannealed steel has some disadvantages including:

- It does not have the same level of corrosion resistance as galvanized steel. Painting is generally recommended to increase its corrosion resistance.

- Manufacturing galvannealed steel requires all the same processing steps as galvanized steel, plus the extra annealing step. This makes it more expensive than galvanized steel to produce.

- The galvannealing process results in a coating with a hard surface. However, this higher hardness compared to galvanized steel can also be prone to brittleness. This limits the use of galvannealed steel in applications where flexibility is required.

- Galvannealed coatings contain zinc, which may release harmful toxins into the environment.

What Are the Chemical Properties of Galvanized and Galvannealed Steels?

The chemical properties of galvanized steel and galvannealed steel are outlined in Table 1:

| Chemical Property | Galvanized Steel | Galvanneal Steel |

|---|---|---|

Chemical Property Weldability | Galvanized Steel Fair | Galvanneal Steel Good |

Chemical Property Corrosion resistance | Galvanized Steel Excellent | Galvanneal Steel Good |

Chemical Property Coating composition | Galvanized Steel Pure zinc | Galvanneal Steel 90% Zinc - 10% iron alloy |

Table Credit: https://eziil.com/galvanneal-vs-galvanized

| Physical Property | Galvanized Steel | Galvanneal Steel |

|---|---|---|

Physical Property Appearance | Galvanized Steel Shiny, silvery-gray metallic appearance | Galvanneal Steel Gray matte appearance |

Physical Property Ductility | Galvanized Steel Good | Galvanneal Steel Excellent |

Physical Property Surface finish | Galvanized Steel Smooth | Galvanneal Steel Rough, matte |

Physical Property Formability | Galvanized Steel Fair | Galvanneal Steel Good |

Physical Property Heat resistance | Galvanized Steel Moderate | Galvanneal Steel Moderate |

Table Credit: https://eziil.com/galvanneal-vs-galvanized

Is Galvanized Steel Stronger Than Galvannealed Steel?

The strength of coated steels like galvanized and galvannealed steels is largely dependent on the properties of the coating and the underlying steel. Galvanized steel has a zinc coating which adds corrosion resistance to standard steel. The surface of galvanized steel is hard, but prone to surface damage like chipping and scratches.

Galvannealed steel has a coating of zinc-iron alloy. This coating is harder than the coating of galvanized steel, and is much more resistant to chipping, scratching, and other types of surface damage.

However, while galvannealed steel’s surface is stronger than that of galvanized steel, the structural strength of both will largely depend on the thickness of the coating and the properties of the base steel.

Is Galvannealed More Rust-Resistant Than Galvanized Steel?

Galvannealed steel is not more rust-resistant than galvanized steel. While galvannealed steel does offer very good rust resistance, the zinc coating of galvanized steel is thicker than the zinc-iron alloy coating of galvannealed steel. This leads to galvanized steel being much more rust-resistant. For harsh applications where rust resistance is the deciding factor, galvanized steel would be more suitable than galvannealed steel.

Are Galvanized and Galvannealed Steel Both Weldable?

Yes. Galvanized steel and galvannealed steel are technically both weldable. However, galvannealed steel has much better weldability than galvanized steel, and it is generally recommended to weld steel parts before galvanization, rather than afterward.

Galvanized steel is coated with zinc. During welding, zinc oxide fumes are released, which are toxic when inhaled. Proper ventilation and protective equipment need to be used whenever welding galvanized steel. Additionally, welding galvanized steel is prone to problems such as cracks, excessive spatter, and lack of fusion in the weld.

Galvannealed steel has a zinc-iron alloy coating. The presence of iron in the coating improves weldability considerably. Galvannealed steel also gives off less fumes than galvanized steel, although protective equipment and proper ventilation should still be used when welding galvannealed steel.

Can Galvanized and Galvannealed Steel Be Used in Form Milling?

Yes. Galvanized and galvannealed steel can both be used in form milling. However, both of these materials offer some challenges. When galvanized steel is exposed to too much heat, the zinc coating can melt or burn off, reducing its corrosion resistance and releasing toxic zinc oxide fumes. Care should be taken to reduce heat, by reducing tool and feed speeds, or using cooling techniques. The zinc coating also tends to be uneven, which can lead to inaccurate machining.

Galvannealed steel is more machinable than galvanized steel, with its thinner, more uniform coating. However, precautions similar to those used for milling galvanized steel should be taken to reduce the risk of toxic fumes.

Summary

This article presented galvanized and galvannealed steel, explained each of them, and discussed their key differences. To learn more about galvanized and galvannealed steel, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.