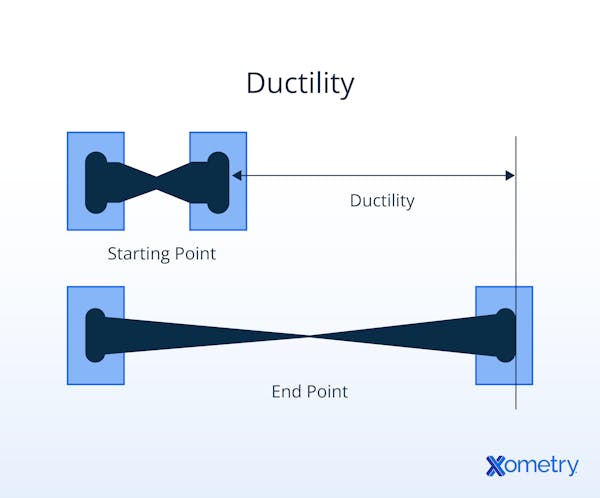

A material’s ductility is defined as its ability to undergo significant plastic deformation before fracture.

Most materials display some elastic behavior when subjected to tensile loads. An applied load (stress) results in an elastic extension (strain) that recovers fully when the load is removed.

However, when stress exceeds the material’s elastic limit, plastic deformation occurs, leading to permanent elongation. Some materials exhibit a gradual transition from elastic to plastic behavior, while others display a distinct yield point where plastic deformation begins. The stress-strain curve of ductile materials typically shows an initial linear region (elastic behavior) followed by a plastic region, where permanent deformation occurs. Ductility is commonly quantified using percent elongation and percent reduction in area.

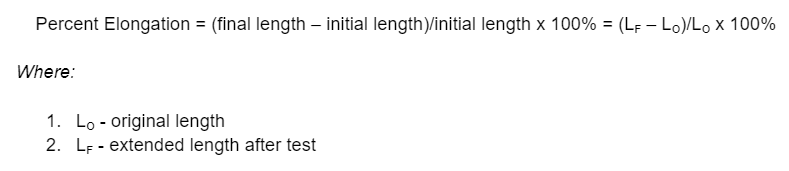

1. Elongation

One method for measuring the ductile behavior of a material sample is using a tensile test machine. This device can measure small longitudinal extensions and recoveries while applying a controlled and continuous load to a sample. Similar equipment/methods are used to measure Young's modulus, which is measured in a material’s elastic region.

Ductility tests, however, are deliberately set to exceed the yield point of the material and cause plastic deformation. The simplest method for quantifying these test results lies in calculating the percentage elongation of the sample until the fracture point occurs.

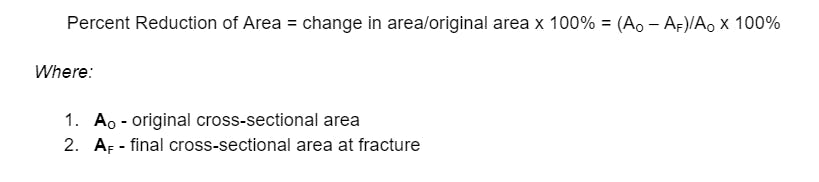

2. Reduction of the Cross-Sectional Area

An alternative approach uses percentage reduction in area (%RA) as the measure. This measures the cross-sectional area before the fracture (A0) and after the material fractures (Af).

What Is Ductility?

Ductility is the ability of a material to distort plastically under tension. In a metal, this occurs due to atomic slip along crystallographic planes. Metallic bonds are characterized by a sea of delocalized electrons, which allow atoms to rearrange without fracture.

In polymers, a related mechanism occurs as long molecular chains slide past each other under stress.

These chains are more loosely coupled than slip planes in metals, preventing close atomic packing. Incidentally, this is why metals tend to be stronger and denser than polymers. In some polymers, stretching can induce crystallinity by aligning polymer chains, as seen in biaxially oriented films such as PET and PP.

What Is the Importance of Ductility?

The importance of ductility is listed below:

- Ductility allows materials to be formed into complex shapes. During bending, the material stretches on the outer side while compressing on the inner side. A material's ability to withstand this plastic deformation without cracking makes it suitable for forming operations.

- Critically useful feature in finished components and devices. Rigid and brittle materials that experience shock and vibrating overloads have a stronger tendency to crack/fail. A good example of this is the use of wrought iron in boilers in the early industrial revolution. Wrought iron is very strong but is quite ductile; however, its fibrous structure and slag inclusions made it prone to fracture under cyclic loading, leading to boiler explosions. The advent of more ductile steels rendered boilers more able to withstand the cyclic stresses of pressure and release without fracturing. Tiny plastic displacements made no functional difference to dimensions but rendered the boilers tougher and much more service-capable.

- The primary mechanism in drawing down metals is to form wires and draw seamless tubes, both of which are valuable areas of engineering materials manufacture.

“Whether you’re drawing wire, forming panels, or absorbing a mechanical shock, ductility is what makes it possible. The more we understand how a material behaves past its yield point, the better we can control the failure, not just postpone it.”Phillip Keane, Design Engineer & Prototyping SpecialistNote from the Editor

Why Calculating Ductility Is Necessary

Calculating ductility is necessary because it determines how much a material can be deformed before it fails. It is an essential factor in designing and selecting materials for safe and enduring use in a wide spectrum of applications. Industries such as construction, automotive, or aerospace rely heavily on the ductility of materials, both for manufacture and use. So, it is a crucial factor in determining the manufacturing processes as well as the strength and reliability of components and structures.

Ductility is quantified in two ways: by measuring the elongation or reduction in the cross-sectional area of a sample at fracture loading. Comparing the results of these tests helps engineers and scientists make informed decisions about the suitability of a particular material for a specific application. It also helps in making improvements in the material's properties to meet their desired requirements. It should be noted that comparisons of test results between the two methods are less reliable and harder to interpret. The relative ductility of materials should generally be compared to same-test results.

How Is Ductility Measured Using the Elongation Test?

Ductility can be expressed as percentage extension at fracture using the equation below:

Ductility measured with elongation test.

How Is Ductility Calculated Using the Tensile Test?

Ductility is expressed as a percentage reduction in cross-sectional area at the fracture. For more information, see our guide on Tensile Strength.

It is calculated by the following equation:

Ductility calculated using tensile test.

Ductility calculated using tensile test.

How Is Ductility Used in Engineering?

Engineers and designers use knowledge of the ductility of a material to determine its suitability for specific applications. Many steel and aluminum alloys are selected in construction and automotive applications due to their ductility, which allows them to absorb energy and prevent catastrophic failures.

Ductility contributes to a material’s ability to withstand impact, vibration, and mechanical abuse without sudden failure, often working in conjunction with toughness. Many safety-critical components, such as bridge cables, pipelines, and aircraft structures, are designed with sufficient ductility to prevent brittle failure and improve survivability under unexpected loads.

Additionally, an understanding of ductility (and its limits) can be used to analyze the cause of material failures. Components that fail due to brittle fracture show that the material or designs did not possess enough survivability in the application.

The ductility of a material can be enhanced through specific heat treatments, alloying strategies, and thermomechanical processing, depending on the material system. By optimizing these processes, engineers can increase the ductility of materials, making them suitable for specific applications.

What Is Ductility Index?

The ductility index is the proportion of total elongation at fracture that is ductile (i.e., plastic in nature). When a part is released before fracture, some component of the material’s extension will recover, elastically. When a tensile-loaded part fractures, a gap will immediately appear at the break, as the material on either side relaxes back the elastic extension that was included in the total extension. Highly elastic material with a short ductile phase will have a low ductility index. A low-elasticity material with a long ductile phase will have a high ductility index.

How Is Ductility Index Calculated?

Ductility index is calculated as:

(Deformation/extension at max load)

(total elastic deformation)

What Are Some Common Units of Measurement Used for Ductility?

Ductility is commonly measured as percent elongation (%EL) or percent reduction in area (%RA), both of which are dimensionless ratios expressed as percentages.

What Factors Affect Ductility?

The ductility of materials is a factor that can be influenced by various treatments that should be selected according to the material class and condition. Listed below are some factors that affect it:

- Increasing Temperature: For most materials, increasing temperature enhances ductility. Higher thermal energy allows atoms to move more freely, reducing resistance to plastic deformation and making slip easier within the crystal structure. Some materials, such as certain ceramics and certain polymers, however, degrade at higher temperatures rather than become more ductile.

- Rate at Which a Material is Loaded: Strain rate significantly affects ductility. At high strain rates, materials have less time for atomic rearrangement, leading to increased brittleness. Conversely, at lower strain rates, materials exhibit more plastic deformation, enhancing ductility.

- Composition of Materials: Materials with a high concentration of impurities or defects may have lower ductility than purer materials. Where an alloying agent is of low ductility, it can significantly affect the behavior of the main constituent.

- Crystal Structure of the Material: Materials with a close-packed crystal structure, particularly metals with face-centered cubic structures, are generally more ductile than materials with a less compact structure, such as body-centered cubic metals.

- Larger Molecular Structure: In polymers, molecular structure affects ductility. For example, polyethylene has significant ductility whereas nylon is more rigid, elastic, and brittle because of the polymer chain strength and entanglement.

- Presence of Other Phases (Inclusions or Second-phase Particles): Second-phase particles and inclusions can influence ductility. Hard phases (e.g., carbides or oxides) act as stress concentrators, promoting localized deformation and fracture. Some engineered second-phase dispersions, however, can enhance ductility by improving dislocation motion.

- Stress State of the Material: Materials under compression may have higher ductility than those under tension, as the compression can lead to the closure of pre-existing cracks and voids, reducing the likelihood of fracture.

Frequently Asked Questions About Calculating Ductility

Can I Calculate the Ductility of Iron?

Yes, the ductility of iron can be calculated. Iron exists in various forms, some of which are ductile and others brittle in response to tensile load. Pure iron (i.e., metallic, atomic iron) is highly ductile, and the ductility can be measured very accurately for a pure sample. Very different results can be expected from cast iron, nodular cast iron, wrought iron, etc.—but the ductility of all varieties is well recorded and understood.

Is Elongation at Break Used To Calculate Ductility?

Yes, elongation at fracture is measured. The percentage increase in length is the most common measure of ductility.

Are All Metals Ductile?

No, metals represent a full range of ductilities, from near zero to the most ductile of all materials. Often, these degrees of ductility are characteristic of chemically near-identical materials in which some properties are altered subtly. For example, gray cast iron is brittle and fractures with little plastic deformation. However, when processed as nodular (ductile) cast iron, its microstructure changes, significantly improving ductility.

Is Gold a Ductile Metal?

Yes, gold is a highly ductile material. Gold has long been recognized as a highly ductile material, with a gram of gold being commonly drawn to a wire measuring 1,000 meters in length. Platinum also exhibits extreme ductility, and in some contexts, it is considered comparable or superior.

Summary

This article presented how to calculate ductility, explained what it is, and discussed the importance of calculating it, as well as common units of measurement for it. To learn more about calculating ductility, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including casting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.