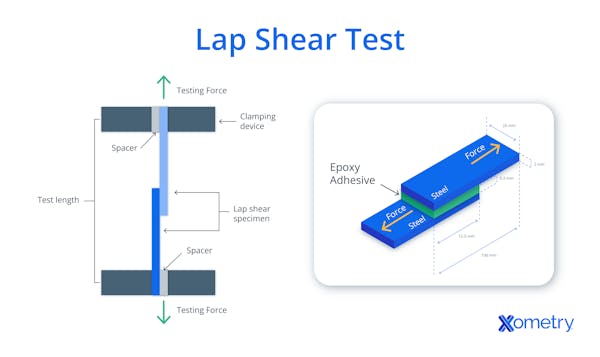

Lap shear testing is a commonly used method for assessing the bond strength between two flat, adhered material samples with a defined contact area. The test is conducted using specialized tensile testing equipment and a standardized setup to ensure highly repeatable and accurate results.

Lap shear testing is used to verify the quality and reliability of adhesive bonds in industries such as aerospace, automotive, electronics, and construction. As a standardized mechanical test, it helps validate consistency in adhesive performance and can reveal variations in materials, surface preparation, or bonding processes.

This article will discuss what lap shear is, how it is conducted and calculated, and outline its key industrial applications.

What Does Lap Shear Mean?

The term lap shear refers to a specific class of mechanical tests used to quantify the shear strength performance of the adhesion or bonding between two material or substrate samples. In a lap shear test, two such samples of materials are bonded together by applying an adhesive or bonding agent as per the manufacturer’s instructions to an overlapping region.

The test requires the application of a highly controlled tensile force parallel to the bonded interface, attempting to pull the two materials apart in a mode that is essentially pure shear. The lap shear strength is measured as the maximum force or stress that the bond can withstand before the onset of failure is observed. Failure modes are variable in that they can be brittle, elastic, followed by fracture, or progressive, depending on the adhesive/joint method, the nature of the substrates, and their relationship to the bonding agent.

This test is widely used in manufacturing, construction, and aerospace to evaluate the quality and reliability of adhesive bonds. It is both a design validation exercise and an in-production quality control/evaluation tool.

Why Is Lap Shear Testing Important?

Lap shear testing is a standardized method used to evaluate the strength and durability of adhesive bonds. It plays a critical role in ensuring the reliability and quality of bonded assemblies by identifying potential defects, process variations, or inconsistencies in the adhesive application that could compromise performance in real-world conditions. This test method supports engineers and manufacturers in selecting the most suitable adhesive and bonding method for specific substrates and operational environments. By providing repeatable and quantifiable results, lap shear testing delivers evidence-based assurance of bond integrity, contributing to optimized product performance and enhanced safety.

Engineers use lap shear tests to validate the suitability of adhesive joint geometry as part of the design process, ensuring that bonded joints can reliably meet safety and performance requirements, especially in critical applications like aerospace and automotive. In general, an application-related factor of safety (FoS) will be applied. Still, a reliable minimum performance must be established in real-world parts or a close analog for this to be valid. The tests aid in optimizing the adhesive application process, leading to better efficiency, cost-effectiveness, and consistency in manufacturing. Where process steps can be shown to add no benefit in ultimate bond strength, they become redundant costs that can be eliminated by repeated and thorough testing. Lap shear testing provides key comparative knowledge in research and development, facilitating the study of bonding properties of new materials, preparation steps, and adhesive formulations. This allows secure and validated advancements in manufacturing processes, materials science, and product reliability outcomes.

How Is a Lap Shear Test Conducted?

A lap shear test evaluates the bonding strength between two materials or substrates. Here's a step-by-step guide on how to conduct a lap shear test:

- Prepare the bonding surfaces according to the adhesive manufacturer’s guidelines. Depending on the adhesive system and substrate material, this may involve cleaning (e.g., with solvents), mechanical abrasion, chemical etching, or the application of primers or accelerators.

- Apply the adhesive to the prepared surfaces and assemble the two substrates with a precisely defined overlap area, which must be accurately measured for the calculation of shear strength. The assembly process—including adhesive application method, alignment, and fixturing—should follow the manufacturer’s specifications to ensure reproducibility.

- Cure the adhesive under the specified conditions, which may involve ambient or elevated temperatures, specific durations, and—in some cases—applied pressure to the bonded area. Cure cycles must be strictly followed to achieve full adhesive performance.

- Secure each end of the bonded specimen in the mechanical grips of a universal testing machine (UTM). Depending on sample geometry and test standard, common grip types include screw-action clamps, hydraulic grips, collet chucks, or custom fixtures with bolted plates.

- Apply a tensile force parallel to the bond line, pulling the substrates apart until failure occurs. A controlled crosshead speed or strain rate—as specified by the relevant test standard—must be maintained to ensure valid results. The force should be applied smoothly without shock loading, as sudden impacts can introduce artificial failure modes.

- Record the maximum load at failure, and calculate the shear strength by dividing this force by the bonded area. For accurate interpretation, all variables—such as adhesive type, curing conditions, substrate material, overlap dimensions, and environmental exposure—should be consistently documented. Repeat tests are typically conducted to ensure statistical validity.

To learn more, see our complete guide on Shear Modulus.

What Materials Are Commonly Tested in Lap Shear?

Lap shear testing is widely performed on a broad spectrum of materials to assess the bonding strength of adhesive joints, including:

- Metals such as steel, stainless steel, aluminum, and titanium

- Plastics

- Wood, leather, and natural fibers

- Ceramics

- Composites such as carbon fiber, glass-reinforced polyester, and Kevlar® materials

- Concrete and stonework

What Does Lap Shear Measure?

Lap shear testing measures the critical performance characteristics of an adhesive bond between material substrates. It assesses the maximum force or stress the adhesive bond can withstand before failure occurs. It provides a quantitative measure of the bonding strength and bond durability, allowing comparison between alternative substrates and adhesive arrangements.

To learn more, see our complete guide on Shear Stress.

What Are the Key Parameters in Lap Shear Testing?

In lap shear testing, a range of key parameters is essential for accurate and usefully interpretable results. These include:

- Bonded Area: This is the most critical parameter. It directly affects the stress distribution within the adhesive bond. A larger bonded area can distribute the load over a broader region, leading to higher lap shear strength.

- Sample Preparation: The quality and consistency of sample preparation, including surface treatment (e.g., cleaning, abrasion, chemical primers), adhesive application (thickness, method, and uniformity), curing conditions (time, temperature, and pressure), and sample alignment, directly affect bond performance and test repeatability.

- Loading or Strain Rate: A standardized crosshead speed or strain rate (as per test standards like ASTM D1002 or ISO 4587) must be defined and consistently applied. Variations in loading rate can affect failure mode and apparent strength, so maintaining a constant rate is essential for valid comparison across samples.

- Temperature and Humidity: Environmental conditions have a significant influence on adhesive performance, particularly for temperature- or moisture-sensitive adhesives (e.g., epoxies, polyurethanes). Testing under controlled or simulated service conditions (such as high humidity or elevated temperatures) may be necessary for applications like automotive, aerospace, or outdoor structures.

- Sample Retainer Design (Grips and Fixtures): The test setup must ensure accurate alignment of the bonded area with the applied load, secure and uniform clamping to prevent slippage or premature failure at the grips, and proper fixture compatibility with the sample geometry to avoid bending or torsional loading that could invalidate the results.

- Data Acquisition: Reliable data logging systems are essential for capturing applied force, displacement, or strain, and time or loading rate, with high-resolution sensors and sufficient sampling frequency to ensure accurate monitoring and allow detailed analysis of load-displacement behavior and failure characteristics.

- Data Analysis: Interpreting lap shear test results requires clearly defined metrics, such as calculating lap shear strength as the maximum load divided by the bonded area, along with failure mode classification and statistical evaluation to ensure meaningful, repeatable conclusions.

- Specimen Geometry: Specimen dimensions must be standardized according to the applicable test method, consistent in width, thickness, and bonded length, and compatible with the testing fixtures to prevent bending, twisting, or uneven loading that could compromise test validity.

How Is Lap Shear Strength Calculated?

Lap shear strength is calculated by dividing the maximum load sustained by the adhesive joint during the test by the bonded area of the overlap region:

Lap Shear Strength (MPa or psi) = Maximum Load (N or lbf) ÷ Bonded Area (mm2 or in2)

The result is typically expressed in megapascals (MPa) or pounds per square inch (psi) and represents the maximum shear stress the adhesive joint can withstand before failure. Several factors influence this value, including adhesive chemistry, substrate material, surface preparation, curing conditions, and environmental exposure during testing.

This provides a quantitative measure of the adhesive bond's strength and is a crucial parameter for assessing the performance and reliability of adhesive joints in various applications.

What Factors Affect Lap Shear Strength?

A range of factors can affect lap shear strength in adhesive bonds, such as:

- Divergent adhesives have varying bonding strengths and characteristics, and their compatibility with the substrate will have a potentially high level of influence on lap shear strength.

- The condition of the substrate surfaces, including cleanliness, roughness, and any pretreatments applied, whether following the manufacturer's recommendations or not, can impact bonding strength.

- Proper adhesive application techniques and even distribution affect the bond's integrity. Excess application, insufficient adhesive, and non-uniform coating can all affect bond quality.

- The adhesive curing time, temperature, and humidity levels can influence bond strength. Some adhesives are very forgiving of poor control, while others are susceptible to cure regimes.

- The type of materials being bonded, their surface energy, and their mechanical properties play a significant role. Low-energy surfaces such as polyethylene and polypropylene can, for example, be bond-enhanced by flame and plasma methods, which significantly alter performance from being generically poor with all adhesives to potentially high strength.

- Parameters such as loading rate, atmospheric humidity, and test temperature can influence test results by altering adhesion properties and/or adhesive material properties.

- Exposure to environmental conditions, such as temperature, humidity, and UV radiation, can affect bond strength over time. For practical lifetime performance evaluation, it's common to apply aging techniques in the form of HALT (highly accelerated life testing) methodology.

- Compatibility between the adhesive and substrate materials is crucial for achieving optimal lap shear strength, which can substantially alter joint performance.

When Is Lap Shear Testing Used?

Lap shear testing is used in many industries and applications whenever the assessment of adhesive bonds plays a role that demands validation. Some examples are:

- Assesses the bonding strength of adhesives used in aircraft components, such as wings, fuselages, and interior structures. Bonding with advanced adhesives is increasingly a mainstay process for resilient, lightweight, and strong structures.

- Evaluates the reliability of adhesive bonds in automotive applications, including car body panels, buffer pads, windshields, and structural components in low-volume and race-vehicle manufacture.

- It tests the effectiveness of adhesives in applications such as curtain walls, cladding, and structural bonding in building construction.

- In manufacturing processes involving the bonding of materials, lap shear testing helps ensure product quality and reliability. Adhesives play an increasing role in manufacturing durable consumer, industrial, and medical products for automated assembly, low assembly height, and high strength.

- In the evaluation of adhesive bonds used in boat construction and repair, lap shear testing plays a central role. Adhesive jointing methods are widespread in the marine sector, offering low localization of stress in coupling composites, which are susceptible to stress concentration and fracture.

- In material science and engineering, lap shear testing is used to study and compare adhesive properties for new applications, methodologies, and formulations.

What Are the Benefits of Lap Shear Testing?

The benefits of lap shear testing include:

- Ensures the reliability and quality of adhesive bonds, helping identify production and design defects or inconsistencies that could lead to failure in real-world scenarios.

- It helps engineers and manufacturers select the most appropriate adhesives, substrates, and bonding methodologies for specific applications, providing repeatable data to assure optimal performance and safety.

- Aids in optimizing the adhesive application process and assessing the efficacy of process alterations, leading to better manufacturing efficiency, cost-effectiveness, and consistency in manufacturing.

- Essential in research and development, studying the bonding characteristics of new materials, assembly methods, joint geometry, and adhesive formulations contributes to advancements in materials science and technology.

What Are the Challenges and Limitations of Lap Shear Testing?

Lap shear testing, while widely used for assessing the strength of adhesive bonds, has several inherent challenges and limitations that can impact the accuracy of results and applicability:

- Strict compliance with adhesive manufacturer-recommended surface preparation and bonding techniques is essential. Even minor deviations can significantly affect test outcomes. However, localized procedural modifications may improve bond performance and should be evaluated carefully.

- Environmental conditions—particularly temperature and humidity—during both specimen preparation and testing can alter bond strength, requiring consistent environmental controls during manufacturing, storage, and testing phases to ensure data reliability.

- Achieving uniform stress distribution across the bonded interface is difficult, particularly with thicker adhesives or mismatched substrates. This non-uniformity can lead to premature or unrepresentative failure, compromising the test’s accuracy.

- Out-of-plane misalignment, differential stiffness, or uneven load application can introduce bending moments or twisting during testing. These mechanical artifacts can lead to peeling forces or localized stress concentrations that distort actual shear performance and potentially invalidate the results.

- The method is less effective for small, thin, or irregularly shaped samples, as clamping and alignment become more complex and error-prone, reducing reproducibility and consistency.

- Lap shear tests primarily evaluate Mode I (interfacial shear) failure, which occurs parallel to the adhesive layer. However, real-world adhesive joints often experience multiple failure modes simultaneously, including Mode II (peel) and mixed-mode failures, making it challenging to extrapolate test results to actual service conditions.

- Results from lap shear testing rarely correlate directly with in-field performance, particularly in dynamic or multi-axial load conditions. Therefore, supplementary testing, such as peel, cleavage, or fatigue testing, is often necessary for a comprehensive performance assessment.

- The test serves primarily as a comparative benchmark under controlled and narrow conditions, offering insights into relative adhesive performance. Engineers must extrapolate results with caution when applying them to different geometries, load paths, or operational environments.

What Standard Does Lap Shear Testing Use?

Lap shear testing is conducted according to various international and industry-specific standards and test methods, depending on the materials, application, and industry involved.

- ASTM D1002: Standard test method for apparent shear strength of single-lap-joint adhesively bonded metal specimens by tension loading (ASTM International).

- ISO 4587: Adhesives—Determination of tensile lap-shear strength of rigid-to-rigid bonded assemblies (International Organization for Standardization).

- ASTM C1583: Standard test method for tensile strength of concrete surfaces and the bond strength or tensile strength of concrete repair and overlay materials by direct tension (ASTM International).

- ASTM D5868: Standard lap shear adhesion test for fiber-reinforced plastics (FRP) co-bonded to similar materials or metals.

- MIL-STD-401B: Test method standard for adhesive bond shear strength (United States Department of Defense).

To learn more, see our complete guide on ASTM Standards.

Frequently Asked Questions About Lap Shear

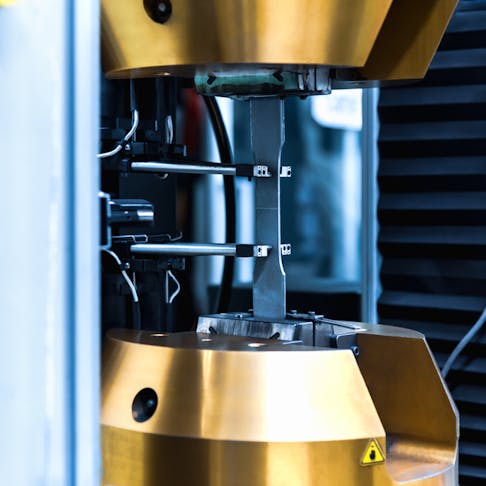

What Device Is Used for Lap Shear Testing?

Lap shear testing is typically conducted using a universal testing machine (UTM), also known as a universal tensile testing machine. This equipment is capable of applying controlled tensile or compressive forces and is equipped with interchangeable grips or fixtures specifically designed for lap shear testing applications.

The machine’s core structure includes a rigid, vertically or horizontally oriented frame with a motor-driven or hydraulically actuated crosshead that moves along a single axis to apply the load. The force capacity of the machine varies based on the application and the mechanical strength of the test specimens. Precision grips, clamps, or fixtures are used to hold the test specimens in place, ensuring proper alignment and even load distribution across the bonded area. These grips are typically tension-based but must be carefully designed to avoid notching effects—mechanical stress concentrations that can lead to premature substrate failure rather than adhesive bond failure.

An integrated load cell sensor accurately measures the applied force throughout the test. The crosshead movement applies tensile stress to one side of the specimen, generating shear stress along the adhesive interface. A data acquisition system, often connected to a PC or software platform, records force and displacement data in real time. This data is essential for analyzing adhesive strength, identifying failure modes, and assessing the performance of bonding materials under shear load.

Is the Lap Shear Test Used To Measure Adhesive Strength?

Yes, the lap shear test is commonly used to measure the adhesive strength of bonded joints. It uses a simplified and regularized test specimen to assess the ability of an adhesive to bond two substrates together and withstand tensile forces applied parallel to the bonded interface in a single mode of strain. This provides a simplified quantitative measure of the adhesive's bonding strength, allowing inter-sample comparisons with a high degree of dependability.

Summary

This article presented lap shear tests, explained them, and discussed how they're conducted and their various applications. To learn more about lap shear tests, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notice

- KEVLAR® is a trademark of E. I. DuPont de Nemours and Company

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.