Two materials that are often said in the same breath are polycarbonate and polyethylene. They’re both plastics but they bring very different properties and uses to the table for manufacturers. This article is a written Venn diagram of sorts that will compare the two plastics to help you best decide which will be the most useful in the products you have in mind.

What is Polycarbonate?

Plastics might literally be known for their plasticity and flexibility, but polycarbonate (PC) is one such material that’s renowned for its impact strength, toughness, and durability. This thermoplastic is made up of polymers surrounding carbonate groups in their chemical structure. When compared to other similar manufacturing materials, PC is relatively inexpensive, but prices will vary depending on its weight and any extra properties. The image below shows an example of a PC part made by Xometry.

What is Polyethylene?

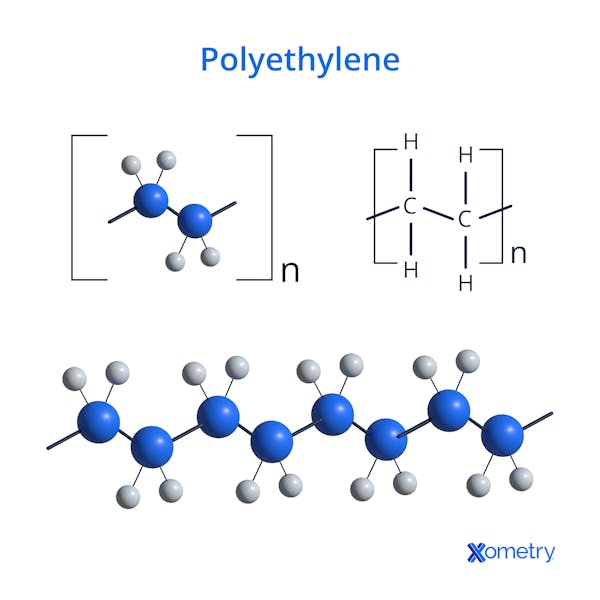

Polyethylene (PE) ranks high up there when it comes to other extremely popular thermoplastics in the world of manufacturing. It’s a homopolymer with chains of ethene molecules and is a useful material for everything from plastic bags to medical implants. The most common formats of this plastic are low-density (LDPE) and high-density (HDPE) polyethylene. LDPE is more elastic as it has a lower density and its chains are made up of side branches within its chemical structure. As shown in the below diagram, HDPE has more closely packed chains, which makes it denser.

| Property | Polycarbonate | LDPE | HDPE |

|---|---|---|---|

Property Optical transmission | Polycarbonate Very high (better than glass) | LDPE Moderate, which can be improved through biaxial orientation | HDPE Poor to none |

Property Density | Polycarbonate 1.2 g/cm^3 | LDPE 0.915–0.96 g/cm^3 | HDPE 0.933–1.27 g/cm^3 |

Property Hardness (Shore D) | Polycarbonate 90–95 | LDPE 42–56 | HDPE 55–69 |

Property Tensile strength (ultimate) | Polycarbonate 28–75 MPa | LDPE 8.96–54 MPa | HDPE 15.2–45 MPa |

Property Yield strength | Polycarbonate 39–70 MPa | LDPE 7.6–14 MPa | HDPE 2.69–200 MPa |

Property Elongation at break | Polycarbonate 10–138% | LDPE 226–650% | HDPE 3–1900% |

Property Modulus of elasticity | Polycarbonate 1.79–3.24 GPa | LDPE 0.152–0.29 GPa | HDPE 0.483–1.45 GPa |

Property Flexural yield strength | Polycarbonate 36–103 MPa | LDPE 14–21 MPa | HDPE 16.5–91 MPa |

Property Flexural modulus | Polycarbonate 0.971–3.1 GPa | LDPE 0.07–0.276 GPa | HDPE 0.5–4.83 GPa |

Property Dielectric constant | Polycarbonate 2.85–3.17 | LDPE 2.27–2.29 | HDPE 2.0–2.6 |

Property Melting point | Polycarbonate 288–316 °C | LDPE 102–113 °C | HDPE 120–130 °C |

Property Max service temperature | Polycarbonate 115–135 °C | LDPE 80–100 °C | HDPE 80–120 °C |

Property Applications | Polycarbonate Medical cameras, lenses, face shields, safety goggles, DVDs, cupboards, kitchen paneling, weather shields, bags, suitcases, windows, greenhouse roofing | LDPE Plastic bottles, plastic bags, trays, computer parts, tubes, containers, caps, fuel cans and drums, trash bins, cables, clips | HDPE Ropes, fishing, sports nets, industrial and decorative fabrics, recycling bins, food and beverage packaging, pipes, milk jugs, toys |

Property Cost | Polycarbonate Around $2.80 per kg or $1.60 per kg for recycled | LDPE About $0.90–$1.10 per kg for granules | HDPE About $8.50 per kg, or around $2.50 for recycled material |

Property Recyclability | Polycarbonate Highly recyclable through sorting, shredding, and remelting | LDPE Highly recyclable except for film products and often more expensive to recycle than to use virgin material | HDPE Highly recyclable except for film products and often more expensive to recycle than to use virgin material |

Polycarbonate vs. Polyethylene Physical Properties

Alternative Materials

There are a few materials that work in similar ways to PC and PE, and are good considerations depending on what application you’re sourcing for:

- Acrylic: While it’s not as strong as PC or PE, acrylic is perfectly workable for windows and other applications. One example is Trivex.

- Polystyrene: More transparent versions of PS can be a good swap for products like light guides, especially since PS is weaker and more easily broken than PC.

- Acrylonitrile butadiene styrene: ABS is perfect if you want a plastic that doesn’t need extreme flexural resilience or ultimate strength. It’s a popular choice for things like 3D printing and injection molding.

How Xometry Can Help

We’re extremely familiar with all the ways in which you can process and manufacture polycarbonate and polyethylene. Through our website, you can get free quotes for related services, like plastic 3D printing, injection molding, and compression molding.

Copyright and Trademark Notice

- Trivex™ is a registered trademark of PPG Industries Ohio, Inc.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.