Polyethylene Terephthalate (PET) is a thermoplastic polymer widely used in the production of plastic bottles, containers, and textiles. PET’s high strength, clarity, and chemical resistance make it ideal for various applications (food and beverage packaging and clothing fibers). Its durability and ability to maintain integrity under pressure contribute to its popularity in packaging and consumer goods.

PET is highly recyclable, contributing to its sustainability in the plastic industry. The ability to reuse PET plastic helps reduce waste, making it an attractive option for industries focusing on environmental impact. Polyethylene terephthalate is integral to the production of products that require strength and clarity, cementing its widespread use in daily consumer items. PET plastic remains a key material in everyday products and innovative packaging solutions.

What is Polyethylene Terephthalate (PET)?

Polyethylene Terephthalate (PET) is a type of polyester formed by the polymerization of ethylene glycol and terephthalic acid. Polyethylene Terephthalate (PET) is widely used in the production of consumer goods, packaging, and industrial products (beverage bottles, microwave-safe containers of Crystallized PET, and textile fibers) due to its strength, durability, and versatility. PET is commonly found in plastic bottles, food containers, and textile fibers. Its resistance to moisture, chemicals, and wear makes it suitable for a variety of applications requiring a strong and long-lasting material. Understanding what is PET reveals its important role in modern manufacturing. The PET material provides an ideal balance of performance and cost-effectiveness, making it a top choice for industries.

How is PET Material Made?

PET is made through a process called polymerization, where ethylene glycol and terephthalic acid are combined under heat and pressure to form long polymer chains. Two common methods for producing PET are direct esterification and ester interchange. Ethylene glycol reacts with terephthalic acid under heat and pressure. Dimethyl terephthalate (DMT) reacts with ethylene glycol in the presence of a catalyst to form a monomer that is then further polymerized into PET via transesterification. The resulting polymer is then processed into various forms (fibers, sheets, or containers). Understanding how PET is made reveals the importance of the methods in determining the final properties of the material. The PET polymerization process ensures that PET is suitable for a wide range of applications, with PET bottles meaning where its durability and recyclability are highly valued.

What is the PET Material Full Form?

The full form of PET material is Polyethylene Terephthalate. Polyethylene Terephthalate is widely used in the production of bottles and containers (food packaging, beverage bottles), and in the form of fibers (clothing, upholstery, and industrial textiles). PET’s durability and resistance to moisture make it ideal for packaging products, while its ability to be easily molded allows for various uses in consumer goods. PET full form highlights its significance in industries like food and beverage packaging, where PET plastic is preferred for its strength and recyclability. Understanding what is PET plastic reveals its critical role in daily life and its widespread applications across various sectors.

What are the Main Challenges in Manufacturing PET Plastic?

The main challenges in manufacturing PET plastic are listed below.

- Thermal Requirements: PET production demands high processing temperatures, which increases energy use and operating costs.

- Waste Generation: Uncontrolled production leads to chemical discharge and non-biodegradable waste that harms ecosystems.

- Recycling Limitations: Recycling requires clean sorting and advanced facilities, which are limited or unavailable in some regions.

- Feedstock Dependency: PET relies on petroleum-based raw materials, making its cost sensitive to oil market fluctuations.

- Mechanical Weakness: Amorphous PET (A-PET) is prone to cracking under stress or low temperatures, which reduces its reliability in rigid packaging..

- Additive Use: Stabilizers and colorants added during production complicate recycling processes and contaminate recycled PET streams.

- Production Emissions: PET manufacturing releases volatile organic compounds (VOCs), though emissions are controlled through industrial environmental standards.

- Water Consumption: Cooling and cleaning processes consume large volumes of water, straining local resources.

- Equipment Wear: Continuous high-temperature operations degrade machinery faster, increasing maintenance needs.

- Limited Biodegradability: PET resists natural decomposition, which leads to long-term accumulation in landfills.

How does PET Plastic Affect the Quality of Products?

PET plastic improves product quality by offering strength, clarity, and protection. The rigid structure resists impact, which prevents damage during transport and handling. The transparent surface allows clear visibility, which improves shelf appeal in packaging. Its barrier properties block oxygen and moisture, which helps preserve food and beverage freshness. PET’s lightweight nature reduces shipping costs without compromising durability. The chemical resistance prevents contamination in pharmaceutical and cosmetic containers. Its formability enables complex shapes, increasing design flexibility for manufacturers. PET plastic recyclability supports sustainability goals in product packaging (food containers, beverage bottles, and personal care packaging), which aligns with environmental branding strategies.

What are the Advantages of Polyethylene Terephthalate Plastic?

The advantages of Polyethylene Terephthalate Plastic are listed below.

- Strength: PET provides moderate impact resistance, protecting contents during transport and storage. Strength helps reduce product damage and loss in packaging applications (beverage bottles, food trays).

- Transparency: High optical clarity improves product visibility, improving shelf appeal and supporting consumer confidence in packaged goods.

- Lightweight: Reduced material weight lowers shipping costs and simplifies handling across supply chains. The efficiency adds to the advantages of PET in distribution.

- Barrier Protection: Effective resistance to moisture and gases helps preserve freshness in food and beverages.

- Thermal Endurance: Stability under heat allows use in hot-fill processes without deformation. The reliability strengthens the advantages of PET in food packaging.

- Design Versatility: Compatibility with various shapes and sizes supports creative packaging for cosmetics, pharmaceuticals, and personal care products.

- Recyclability: Compatibility with global recycling systems promotes circular use and reduces landfill waste. The environmental benefit reinforces the advantages of PET in sustainability.

What are the Disadvantages of Polyethylene Terephthalate Plastic?

The disadvantages of Polyethylene Terephthalate Plastic are listed below.

- Non-Biodegradability: PET remains in landfills and oceans for decades, which increases long-term pollution and harms marine life.

- Thermal Sensitivity: Exposure to heat and ultraviolet rays weakens the PET structure, which reduces its reliability in outdoor use.

- Rigidity: PET lacks natural flexibility, which restricts its use in bendable or soft packaging without chemical alteration.

- Chemical Leaching: Under extreme heat or improper use, PET releases trace levels of compounds, and food-grade PET complies with regulatory safety standards (Food and Drug Administration and European Food Safety Authority) to prevent harmful leaching in approved applications.

- Energy Demand: Production requires high temperatures and pressure, which increases resource consumption and carbon emissions.

- Recycling Challenges: Contaminated PET is difficult to process, which limits its reuse and adds to waste volume.

- Color Limitations: The addition of dyes or colorants reduces PET's natural transparency, which affects visual appeal in colored packaging (personal care products, beverage containers).

- Microplastic Formation: Fragmented PET contributes to microplastic spread, which affects soil and water quality.

What are the Properties of Polyethylene Terephthalate?

The properties of Polyethylene Terephthalate are listed below.

- Mechanical Strength: High tensile resistance allows PET to withstand pressure and impact during transport and storage. The feature supports the properties of PET in protective applications.

- Optical Clarity: Transparent surface improves product visibility, improving presentation in retail packaging (bottled beverages, clamshell containers).

- Moisture Resistance: Low water absorption prevents spoilage in food containers and beverage bottles.

- Chemical Stability: Inert behavior protects contents from contamination, which benefits pharmaceutical and cosmetic packaging.

- Thermal Tolerance: PET maintains structural integrity during hot-fill processes due to its thermal stability. Heat-set PET variants allow limited sterilization use in food-grade applications.

- Dimensional Stability: Maintains shape under stress, which supports consistent performance in molded components.

- Lightweight Composition: Low density reduces shipping weight, which improves efficiency in logistics.

- Recyclability: Compatibility with recycling systems promotes reuse, which strengthens the environmental properties of PET.

What is the Density of Polyethylene Terephthalate?

The density of Polyethylene Terephthalate (PET) ranges from 1.33 to 1.40 g/cm³, depending on its crystallinity. PET’s moderate density supports a balance of structural strength and lightweight form, although its strength and impact resistance are primarily derived from its molecular structure and degree of crystallinity. The moderate density allows PET to offer durability and structural integrity without being overly heavy, making it suitable for applications (packaging, bottles, and textiles). The density of PET provides a balance between strength and lightweight properties, improving its versatility. Understanding PET density is essential in selecting it for products where durability and weight are critical factors (Density and Weight).

What is the Melting Point of Polyethylene Terephthalate?

The melting point of Polyethylene Terephthalate (PET) ranges from 255 -265°C (491°F - 509°F), depending on its crystallinity. The high melting point allows PET, heat-set variants, to maintain dimensional stability in applications exposed to moderate heat (hot-fill packaging and thermal processing). PET is used in products (bottles, food containers, and automotive parts) that require resistance to deformation at elevated temperatures. The material's ability to withstand heat without losing strength or shape is essential for ensuring performance in demanding environments.

What is the Chemical Formula of Polyethylene Terephthalate?

The chemical formula of Polyethylene Terephthalate (PET) has the chemical formula (C10H8O4)n, where "n" indicates the number of repeating units in the polymer chain. The linear and semi-crystalline molecular structure of PET contributes to its durability and moderate thermal resistance, making it suitable for applications that require materials to endure stress and elevated temperatures (food containers, hot-fill packaging). Its repeating units in the polymer chain provide strength, while its ability to mold PET into various shapes enables its use in a wide range of products, from containers to fibers. The strength and thermal stability of PET plastic make it ideal for consumer goods and industrial applications.

What is the Structure of Polyethylene Terephthalate?

The structure of Polyethylene Terephthalate (PET) consists of repeating ester-linked units formed from terephthalic acid and ethylene glycol, creating a linear polymer chain. The units form long polymer chains that provide strength and stability to the material. Aromatic rings within the PET backbone restrict rotational movement, contributing to its rigidity, dimensional stability, and resistance to deformation under load. The presence of the rings makes PET suitable for applications that require durability and high performance.

The PET structure enables the material to be molded into various forms while maintaining strength and resistance to environmental stress. Its structural advantage makes PET a popular choice for products (packaging, textiles, and automotive parts).

What is Polyethylene Terephthalate Used for?

Polyethylene Terephthalate (PET) is used in a variety of applications, including plastic bottles, containers, textiles, and packaging materials. The Polyethylene Terephthalate is widely used in the beverage industry for making bottles due to its strength, lightweight nature, and ability to preserve the contents. PET is used to produce polyester fibers, which are known for their durability and versatility in clothing and industrial fabrics in the textile industry. It is used in food containers and packaging materials where clarity and resistance to moisture are important.

PET is favored for its strength, optical clarity, and moldability. The material is easily molded into different shapes, which makes it suitable for diverse industrial uses. Its ability to maintain structural integrity while being lightweight makes it a preferred choice in applications ranging from household goods to electronics packaging. The material of Polyethylene Terephtalate offers a balance between performance and cost, supporting its widespread use across sectors (consumer goods, medical-grade PETG, and textiles).

Over half of synthetic fibers found around the world are made from PET. When used as a fabric or a fiber, PET is generally called “polyester”, and when it is in more solid forms, like for packaging or containers, it’s referred to as “PET” or “PET resin.” PET is made with a mix of two elements that form a polymer chain: ethylene glycol (“MEG” from monoethylene glycol) and purified terephthalic acid (“PTA”). MEG usually comes from natural gas, and PTA from p-xylene that’s made from crude oil. It can also be made another way, by using MEG and dimethyl terephthalate (DMT) (C6H4(CO2CH3)2).

In the PET-making process, a catalyst (usually an antimony or titanium compound) and a stabilizer (phosphite) are added. To hide any yellow hues, a bluing agent, like cobalt salt, is also used. Once the chemical reaction happens, the strands—which will now look a little like spaghetti—will be extruded so that the material can be processed and made into whatever is necessary. Once the strands have cooled, they are cut into small resin pellets, which can then be melted to make extrusion or plastic injection molding easier. PET can be recycled (it’s also known as a “green” plastic) because it won’t burn in high temperatures; instead it will liquefy. It doesn’t absorb or interfere with microwave radiation (which is why many ready meals are PET packaged), and it won’t shatter, fracture, or break either.

Other perks of PET are its electrical insulating, gas (i.e., oxygen and carbon dioxide), and moisture barrier properties. Its gas permeability is very low (especially with carbon dioxide), and it’s not reactive with food or water. If quenches (cooled rapidly), it can be used for making see-through products. At high temperatures, PET absorbs moisture from the atmosphere at high temperatures, and if it’s reinforced with glass fiber, it can become even stronger. This might make it bend, or warp, though. PET temperatures to know about are listed below:

- Operating range: 60°C–130°C

- Processing range: 120~220°C

- Glass transition: 67–81°C

- Melting point: 260°C

- Glass conversion: ~165°C

PET’s heat resistance is lower than other polymers, and it can only really be injection molded with a screw-type machine. The material, although recyclable, isn’t biodegradable. In addition, PET resin can oxidize and change the taste of PET-packaged food or drinks when they’ve been on the shelf for a long time.

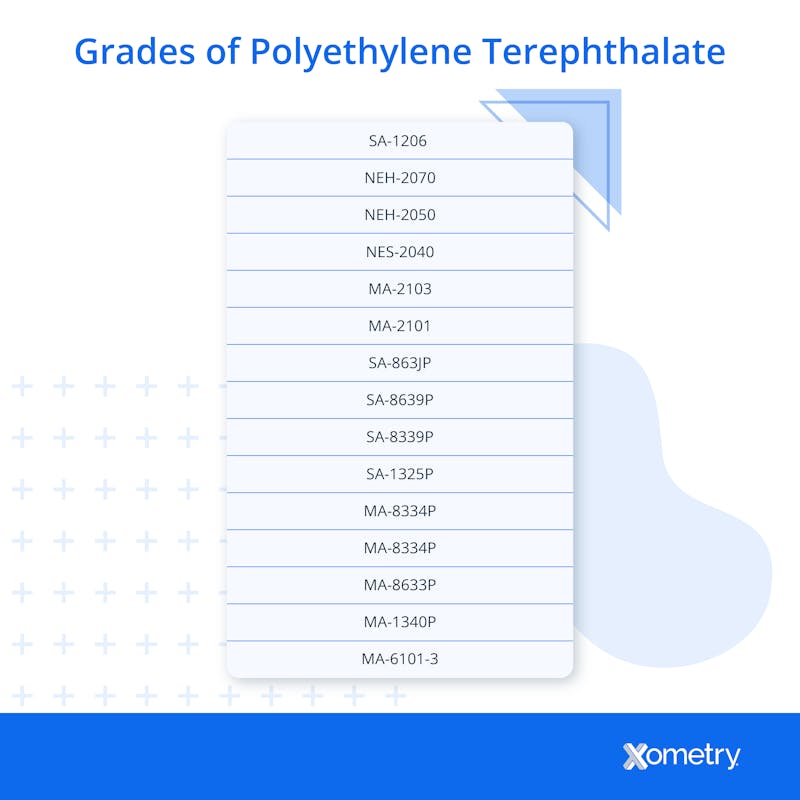

PET Grades

The following is a list of PET grades:

What is PET Material Used for in Medical Applications?

Special grades of Polyethylene Terephthalate (medical-grade PET or PETG) are used in medical applications (sterilized containers and medical packaging), where strength and chemical resistance are required. PET's resistance to chemicals and its ability to withstand sterilization processes make it suitable for products that come into direct contact with patients. PET is used for medical packaging (vials, trays, and blister packs), where maintaining the sterility of the contents is essential.

The chemical resistance of PET, along with compatibility with sterilization methods (ethylene oxide and gamma radiation), makes it suitable for use in medical packaging and containers.. PET is durable and does not degrade easily, making it suitable for long-term use in medical containers and vials. PET fibers are used in vascular graft applications in some cases. The material's versatility allows it to be molded into various shapes, providing flexibility for different medical product designs. PET material is widely valued for its strength, clarity, and compatibility with medical-grade sterilization techniques.

Can Polyethylene Terephthalate be Used in Medical Implants?

No, Polyethylene Terephthalate (PET) can not be used for permanent medical implants. PET is not used for rigid or load-bearing permanent implants, but is used in permanent medical applications as fibers (vascular grafts, surgical meshes, and heart valve components). PET's strength, biocompatibility, and ability to withstand sterilization make it suitable for short-term medical applications. It is used in temporary medical devices (stents, sutures, and drug delivery systems). PET is favored for its uses due to its ability to resist wear and corrosion while maintaining its integrity over time.

PET is sterilized using methods (ethylene oxide and gamma radiation), making it suitable for sterile medical devices and packaging. Its structural strength and flexibility allow it to be molded into various forms for different medical applications. The properties of Polyethylene Terephthalate make it a viable option for products that require short-term use in the medical field, while PET is not ideal for permanent implants. The PET material continues to be valuable in temporary medical applications due to its characteristics.

What are the Applications of PET Material in Construction?

The applications of PET material in construction are listed below.

- Insulation: PET is used in insulation films and multilayer barrier materials where moisture resistance and dimensional stability are needed, rather than for direct thermal insulation..

- Piping Systems: PET is not used for plumbing pipes but is included in multilayer barrier films or composite structures where corrosion resistance is required.

- Roofing Materials: PET is used as a reinforcement layer in roofing membranes for its tensile strength and wear resistance, helping the material withstand mechanical stress and weathering.

What Role Does PET Plastic Play in Automotive Safety Features?

The roles that PET plastic plays in automotive safety features are listed below.

- Airbags: PET is not used in airbag inflation systems. Airbag components rely on high-strength metals and nylon fabrics to manage the pressure and durability demands during deployment.

- Safety Glazing: PET is used as an interlayer film in laminated automotive glazing systems, where it adds impact resistance and helps prevent shattering during collisions.

- Seatbelts: PET fibers are used in seatbelt materials because of their strength and durability, ensuring reliable passenger protection.

What are the Benefits of PET Plastic in Food Packaging?

The benefits of PET plastic in food packaging are listed below.

- Non-Toxic Properties: PET is approved by regulatory agencies (FDA, EFSA) for direct contact with food. PET does not release harmful substances beyond established safety limits when used under recommended conditions.

- Durability and Shelf Life: PET is resistant to moisture and provides excellent protection for food, extending shelf life. It maintains the integrity of food products, preventing spoilage.

- Recyclability: PET is widely recyclable, supporting sustainability efforts in the food packaging industry. The material is reused, reducing waste and environmental impact.

What is the Cost of Polyethylene Terephthalate Plastic Compared to Other Plastics?

Polyethylene Terephthalate (PET) is more cost-effective than other plastics (Polycarbonate and Polyvinyl Chloride). PET is more cost-effective than Polycarbonate (PC) and Polybutylene Terephthalate (PBT) due to high production volumes, lower raw material costs, and efficient manufacturing processes. Its affordability, combined with desirable properties (strength, durability, and recyclability), makes it a popular choice for packaging and textile applications. Polycarbonate is more expensive due to its superior impact resistance and optical clarity, while PBT’s higher cost is attributed to its excellent chemical resistance and dimensional stability. PET’s cost-effectiveness, when compared to other plastics, has driven its widespread use across industries, including food packaging and clothing, where cost, performance, durability, and environmental impact are key considerations.

How is PET Plastic Recycled?

PET plastic is recycled through mechanical processes involving cleaning, shredding, and re-melting, followed by pelletization before being used to manufacture new products (bottles, textiles, or packaging materials). The recycling process involves cleaning, shredding, and melting the plastic before it is molded into new forms. Contamination remains a significant challenge despite improvements in PET recycling rates. Impurities from other materials reduce the quality of the recycled PET, making it harder to reuse effectively. Ongoing advancements in sorting technologies and recycling practices aim to increase the efficiency and quality of PET recycling.

Is Polyethylene Terephthalate (PET) More Resistant to Fatigue than Acrylonitrile Butadiene Styrene (ABS)?

No, Acrylonitrile Butadiene Styrene (ABS) is not more resistant to fatigue than Polyethylene Terephthalate (PET). PET has superior fatigue resistance due to its semi-crystalline molecular structure, which supports long-term performance under cyclic loading. ABS has high impact strength due to its rubber-modified structure, but its amorphous configuration makes it more susceptible to fatigue failure compared to PET under repeated stress. PET maintains its structural integrity under cyclic stress, making it suitable for fatigue-prone applications where repeated loading occurs. The different applications of PET and Acrylonitrile Butadiene Styrene (ABS) reflect their fatigue resistance. ABS is commonly used in applications requiring high impact resistance (automotive parts and protective housings), while PET is preferred for applications demanding fatigue resistance and dimensional stability (mechanical parts, reinforced components, and containers).

Does Polyethylene Terephthalate (PET) Have Better Dimensional Stability than High-Density Polyethylene (HDPE)?

Yes, Polyethylene Terephthalate (PET) has better dimensional stability than High-Density Polyethylene (HDPE). PET’s semi-crystalline structure provides greater resistance to deformation under heat, stress, and load, making it suitable for applications requiring tight tolerances and long-term structural consistency. PET has a semi-crystalline structure, which provides moderate resistance to shape distortion. HDPE maintains form well under chemical exposure and impact, but it has higher thermal expansion and lower stiffness than PET, reducing its dimensional precision under mechanical or thermal stress. HDPE retains its shape even under moisture, temperature, or impact-related stress, making it suitable for outdoor piping and storage containers. PET exhibits low thermal expansion and minimal creep, offering high dimensional tolerance in molded components and packaging applications. HDPE’s flexibility allows it to absorb impact, but it is more prone to warping and creep under prolonged mechanical strain compared to PET. PET provides more reliable long-term performance than High-Density Polyethylene (HDPE) in applications where dimensional accuracy and structural rigidity are critical.

Is Polyethylene Terephthalate (PET) Easier to Dye than Polyethylene (PE)?

Yes, Polyethylene Terephthalate (PET) is easier to dye than Polyethylene (PE). PET’s chemical structure, which contains ester groups, allows it to absorb dye more readily compared to PE. The polar nature of PET’s molecular structure enables it to form stronger bonds with dye molecules, leading to better color uptake. PE's non-polar structure makes it less receptive to dyes, requiring additives or higher temperatures for effective coloring.

The dyeability of PET supports flexible manufacturing and branding by allowing a wide range of color options in textiles and molded packaging. Products made from PET (bottles and textiles) are easily customized for different brands or designs. The Polyethylene (PE) material requires effort and cost to achieve the desired color.

Does Polyethylene Terephthalate (PET) Offer Better Surface Gloss than High Impact Polystyrene (HIPS)?

Yes, Polyethylene Terephthalate (PET) offers better surface gloss than High Impact Polystyrene (HIPS). PET provides superior gloss retention, giving it a shiny, smooth finish that refines its visual appeal. High Impact Polystyrene (HIPS) exhibits lower surface gloss and is more prone to dulling over time, under UV exposure, or from surface abrasion, compared to PET.

Surface gloss plays an important role in product presentation, particularly in packaging and consumer goods. PET’s glossy finish is ideal for products (beverage bottles, food containers, and cosmetic packaging) where aesthetics are important to attract consumers. The High Impact Polystyrene (HIPS) material, while durable, does not offer the same level of gloss, making it less suitable for high-visual applications.

Is Polyethylene Terephthalate (PET) More Suitable for Thin-Wall Applications than Polylactic Acid (PLA)?

Yes, Polyethylene Terephthalate (PET) is better suited to thin-wall applications than Polylactic Acid (PLA). PET is commonly used for thin-wall containers due to its strength, rigidity, and ability to maintain structural integrity under stress. Its toughness allows PET to be molded into thin walls without compromising its durability, which is essential for applications (beverage bottles and food containers).

The difference between PLA and PET is that PLA is biodegradable and compostable under controlled conditions, but it is more brittle and less impact-resistant than PET. The lower strength of Polylactic Acid (PLA) makes it less suitable for applications requiring thin walls and structural support. PET’s superior mechanical properties make it the preferred choice for lightweight, thin-walled products that must withstand handling and pressure.

Does Polyethylene Terephthalate (PET) Have Better Electrical Conductivity than Polystyrene (PS)?

No, Polyethylene Terephthalate (PET) does not have better electrical insulating properties than Polystyrene (PS), as they have similar low conductivity, making them unsuitable for conducting applications. Neither PET nor PS is considered a good electrical conductor, as Polyethylene Terephthalate and Polystyrene are insulating materials. Its electrical conductivity remains in the same insulating range as Polystyrene, with no practical performance advantage in conductivity, but PET has a slightly different molecular structure. Polyethylene Terephthalate and Polystyrene materials are used in applications where electrical conductivity is not a primary requirement. The electrical properties of PET and Polystyrene (PS) make them suitable for insulation purposes (in electrical housings and packaging). The materials prevent the flow of electricity, ensuring safety in products where electrical conduction is unwanted.

Is Polyethylene Terephthalate (PET) More Resistant to High-Pressure Environments than Nylon (PA)?

No, Polyethylene Terephthalate (PET) is not more resistant to high-pressure environments than Nylon (PA). Nylon performs better in high-pressure applications due to its superior tensile strength and resistance to mechanical stress. PET, while strong and dimensionally stable, is more brittle and less impact-resistant than Nylon, limiting its use in high-pressure or high-load mechanical applications.

Nylon is preferred in high-stress, high-pressure environments (automotive parts, industrial equipment, and gears) where durability and flexibility are essential. The molecular structure of Nylon (PA) allows it to maintain its integrity under pressure without significant deformation, making it more suitable for demanding applications.

Does Polyethylene Terephthalate (PET) Perform Better in Vacuum Forming Applications than Polybutylene Terephthalate (PBT)?

Yes, Polyethylene Terephthalate (PET) performs better in vacuum forming applications than Polybutylene Terephthalate (PBT). PET is more commonly used in vacuum forming due to its superior formability, which allows it to stretch and conform to molds without cracking. PBT, while durable and strong, lacks the thermoformability required for vacuum forming, making it more suitable for injection molding applications than for creating complex or flexible shapes.

Factors influencing material selection in vacuum forming include the material’s ability to mold easily, heat resistance, and flexibility. PET’s lower melting point and ease of processing make it ideal for applications (packaging and consumer goods). The use of Polybutylene Terephthalate (PBT) is common for applications requiring high strength and thermal stability, but not necessarily for vacuum forming processes.

Is Polyethylene Terephthalate (PET) More Stable Under Extreme Temperature Changes than Acetal (POM)?

No, Polyethylene Terephthalate (PET) is not more stable under extreme temperature changes than Acetal (POM). Acetal offers better thermal stability, even with significant temperature fluctuations, without losing its mechanical properties. PET becomes brittle at low temperatures and softens under moderate heat, limiting its use in applications exposed to wide or extreme temperature swings.

Acetal's high resistance to temperature changes makes it suitable for applications in the automotive and aerospace industries, where components are subject to rapid temperature variations. PET is more commonly used in applications that do not require frequent exposure to extreme temperatures. The superior thermal stability of Acetal (POM) makes it the preferred choice for environments that demand high performance under temperature stress.

How Xometry Can Help

Xometry offers injection molding services and 3D printing using a variety of materials. Contact us for a quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.