When comparing polypropylene vs. polyethylene you’ll find they have a lot in common. They find use across many industries, and both polymers have very similar chemical structures. However, there are also some key differences between the two that need to be considered.

Polypropylene (PP) and polyethylene (PE) both belong to the thermoplastic family. Depending on the grade, they can be melted and reformed multiple times. Polypropylene is a polyolefin, which means that it is made up of repeating units of propylene. Polyethylene, on the other hand, while also a polyolefin, can be made from a variety of different monomers, the most common being ethylene.

Of the two, polypropylene can withstand higher temperatures. It is more rigid and has a higher melting point than polyethylene. Also, polypropylene is used in food packaging, as it is food-safe and moisture-resistant. Polypropylene finds its way into packaging, carpets, ropes, and plastic parts.

Polyethylene is widely used in packaging as well since it is very strong and durable. This includes food packaging. Other common places to find polyethylene are cable and wire insulation, toys, buckets, and grocery bags. In this article, we will compare polypropylene vs. polyethylene in terms of its properties, applications, and more.

What is Polypropylene?

Polypropylene (PP) is a thermoplastic polymer that belongs to the polyolefin family. It is made up of repeating units of propylene and can be made through various different manufacturing processes, including injection molding and extrusion. For more information, see our guide on All About Polypropylene.

Polypropylene is a versatile polymer that can be found in: packaging for food and other consumer goods, carpets, and ropes. Some common characteristics of polypropylene include

- High melting point

- Good chemical resistance

- Good moisture resistance

- Rigidity

Since polypropylene has a high melting point, it can be used in applications where it needs to withstand higher temperatures. Polypropylene is also moisture-resistant, which makes it a good choice for food packaging. Plus, its inherent rigidity gives it good strength and durability.

What is Polyethylene?

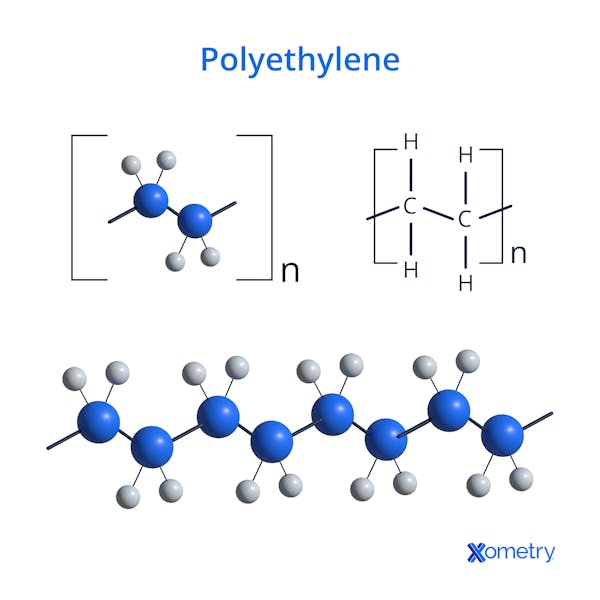

Polyethylene (PE) is also a thermoplastic polymer that belongs to the polyolefin family. It can be made from a variety of different monomers, the most common of which is ethylene. Polyethylene products can be manufactured through many different processes, including extrusion and injection molding. For more information, see our guide on What is Polyethylene.

This versatile polymer can be used in various applications, including houseware, bottles, wire insulation, toys, etc. As polyethylene is available in multiple different grades, it can be tailored to meet specific needs. Some common characteristics of polyethylene include:

- Good chemical resistance

- Good moisture resistance

- High impact strength

- Flexibility

The most common polyethylene grades are low-density polyethylene (LDPE) and high-density polyethylene (HDPE). LDPE is a soft, flexible polymer that is often used in food packaging and grocery bags. HDPE is a stronger, more rigid polymer that is often used in bottles, pipes, and buckets.

Polypropylene vs. Polyethylene: Applications and Uses

Both polypropylene and polyethylene are versatile polymers that can be used for many different purposes. Some common uses for polypropylene and polyethylene include:

- Food packaging

- Packaging for other consumer goods

- Carpets

- Ropes

- Buckets

- Grocery bags

The two polymers differ, however, and some products can make use of one but not the other. For example, polypropylene is often used in the production of non-translucent materials (though it can be made translucent through a chemical treatment called bleaching). Some polyethylene materials, meanwhile, are naturally translucent.

Comparison of Physical Properties

Table 1 below highlights some physical properties of polypropylene vs. polyethylene:

| Physical Properties | Polypropylene | Polyethylene |

|---|---|---|

Physical Properties Chemical Resistance | Polypropylene High chemical resistance | Polyethylene Very high chemical resistance |

Physical Properties Tensile Strength | Polypropylene 0.5-3.0 GPa | Polyethylene 3.7-19 Gpa |

Physical Properties Impact Tolerance | Polypropylene Good impact tolerance or resistance | Polyethylene Good impact tolerance or resistance |

Physical Properties Water Absorption | Polypropylene Resists water absorption | Polyethylene Resists water absorption |

Physical Properties Surface Hardness | Polypropylene 92 on the Rockwell R scale | Polyethylene - |

Physical Properties Translucency | Polypropylene Naturally opaque in color but can be made translucent | Polyethylene Some variants are translucent |

Physical Properties Static Charge | Polypropylene Higher static charge | Polyethylene Lower static charge |

Physical Properties Purity | Polypropylene Is often co-polymerized with ethylene | Polyethylene The purity level is often 100% |

Physical Properties Operating Temperature | Polypropylene 82.2 °C (180 °F) | Polyethylene - |

Physical Properties Melting Temperature | Polypropylene 163.8 °C (327 °F) | Polyethylene Low-density polyethylene melts at 110 °C (230 °F) while High-density polyethylene melts at 120 °C (250 °F) |

Cost Comparison of Polypropylene vs. Polyethylene

Polypropylene costs about $0.55-0.80 per kilogram while polyethylene costs about $0.80-1.60 per kilogram. The actual cost depends on the specific grade that is being used, but polypropylene is generally less expensive than polyethylene.

Alternative Materials to Polypropylene and Polyethylene

Listed below are some alternative materials to both polypropylene and polyethylene:

- Polystyrene: Polystyrene is a rigid thermoplastic polymer in the polyolefin family. It can be made from a variety of monomers, the most common being styrene. Injection molding is used to manufacture many polystyrene products. Polystyrene is commonly used in packaging, insulation, and construction.

- Polyvinyl Chloride (PVC): PVC is a thermoplastic polymer that belongs to the polyolefin family. Vinyl chloride is the most common monomer used in its production. PVC can be produced in both rigid and flexible variations and is often seen in the form of pipes, cables, and window frames. Dioxins are created as by-products of the PVC production process, which can have negative effects on the environment

- Polycarbonate: Polycarbonate is a thermoplastic polymer that belongs to the polyolefin family. It can contain a variety of monomers, the most common of which is bisphenol A. Polycarbonate is often used as a substitute for polypropylene in applications that require both impact resistance and transparency.

Xometry provides a wide range of manufacturing capabilities including 3D printing, CNC machining, injection molding, laser cutting and more for prototyping and production parts. Get your instant quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.