From machining to injection molding to 3D printing with it, we are all too familiar with working with nylon at Xometry. “Nylon” actually refers to the family of synthetic polymers made of polyamides that have repeating units linked by amide bonds. It’s a popular material in many industries as it can be melted and shaped into many different fibers, fabrics, films, and shapes. To enhance its properties, nylon polymers can be mixed with different additives.

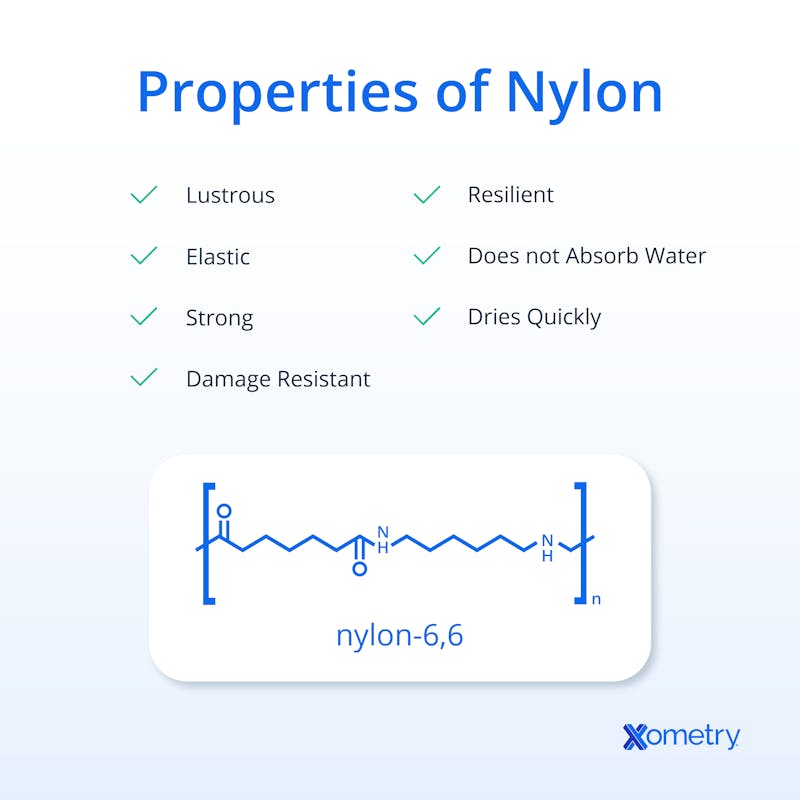

Properties of Nylon

We will explain the different properties of nylon, specifically its lustrousness, elasticity, strength, damage resistance, resiliency, moisture resistance, and quick-drying nature.

1. Nylon is Lustrous

Nylon is shiny and lustrous in and of itself, but it can also be made to have varying levels of sheen (very lustrous, semi-lustrous, or dull). This is one reason it is often used as a fabric. Parts 3D printed from nylon, such as our nylon 12 materials through the SLS and MJF processes, will naturally come out with a matte sugar cube-like finish. We can; however, vapor smooth SLS and MJF nylon parts to improve their lustrousness.

2. Nylon is Elastic

When heated to its melting point, nylon’s molecular structure changes into either a soft solid or thick fluid. To get a bit technical, its molecular chains are arranged randomly like tangled coils, which allow it to easily change shape. Two main regions make up its structure when it’s cooled down (crystals and amorphous). It’s the amorphous parts that give nylon its ability to stretch and then easily return to its original shape.

3. Nylon is Very Strong

Nylon on its own has high tensile strength and durability, making it suitable for applications that require the material to survive impacts. In some applications, nylon plastic is filled with 10-40% glass fibers to increase tensile strength further. Xometry offers glass-filled nylon for both SLS and MJF 3D printing, as well as with our injection molding services. While strength is increased in such situations, the glass fibers also make the material very stiff. No glass fill means that the plastic will bend and yield more before a potential break. With the addition of fibers (especially in a higher percentage), the break (or failure) comes earlier, with minimal bending. However, for reinforced nylon, the resulting tensile strength can be up to 70% higher than un-filled nylon plastic.

4. Nylon is Damage-Resistant

Nylon has a chain of alternating chemicals that makes its bonds extra strong, oil- and chemical-resistant (for the most part), and able to withstand exposure to various substances without being damaged easily. But let’s start from the beginning. A blend of coal, water, and oxygen is used to make nylon. A polymer is then thrown into the mix, creating two chemicals: hexamethylenediamine (HD) and adipic acid (diacid). When combined, HD and diacid make up a polymer chain. This is the part when they start alternating, giving nylon its superior strength and damage resistance.

5. Nylon is Resilient

Nylon’s resilience and durability are all in its synthetic make-up. Because nylon can be molded into virtually any shape, it is useful for products that require flexibility. Nylon's flexibility comes from its natural elasticity, which we mentioned before. This makes it great for applications that require living hinges or snap-fits.

6. Nylon Can Absorb Water

Nylons are hygroscopic and absorb moisture from the air as a function of ambient humidity. Different levels of moisture will cause the polymer to react in different ways. First off, its dimensions will change, but more of an issue is the fact that moisture acts as a plasticizer. This will lower the glass transition temperature (Tg) and, as a result, the elastic modulus will also drop to temperatures below the Tg. Polyamide is a great electrical insulator when it’s dry. While it can hold some water, nylon is not as absorbent as some other materials like wool or cotton. For parts made of nylon with thicker walls, water does not permeate all the way through the material. For example, when we submerge and dye SLS 3D-printed nylon parts, the dye is only present in the first 0.25mm or so.

7. Nylon is Quick-Drying

Despite its ability to hold some level of moisture, nylon is famed for how much quicker it dries than other similar materials. Its wicking characteristics make it a firm favorite in the fabrics industry. If you have a favorite outdoor garment advertised as “fast drying,” there is a good chance that it is partially, if not entirely, made of nylon.

Physical Properties of Nylon

Compared to other plastics, nylon has more strength and higher levels of temperature- and friction-resistance. Here’s a brief breakdown of its physical properties:

- Elasticity: Nylon has a breaking extension of 20–40%.

- Stiffness: 20-40 gm/density

- Moisture regain: 3.5-5%.

- Specific gravity: 1.14

- Abrasion resistance: Excellent

- Dimensional stability: Good

- Softening point: Nylon 6,6 – 229°C and nylon 6 – 149°C.

- Melting point: Nylon 6,6 – 252°C and nylon 6 – 215°C.

- Resiliency: Excellent

Chemical and Environmental Exposure Properties of Nylon

The chemical properties of nylon relative to exposure to various substances and environmental conditions are as follows:

- Acid: Nylon attacked by mineral acids is disintegrated or almost dissolved. It is inert to dilute acetate acid and formic acids. It is dissolved in concentrated formic acid. Nylon is attacked by mineral acid but resistant to dilute boiling organic acid.

- Bleaches: Nylon is not attacked by oxidizing and reducing bleaches but may be harmed by chlorine and oxidizing solid bleaches.

- Organic solvent: Most organic solvents have little or no effect on nylon. Phenol metacresol and formic acid dissolve the fiber, but solvents used in stain removal and dry cleaning do not damage it.

- Alkali: Nylon is substantially inert to alkalis.

- UV-resistance: Nylon gradually loses strength and may yellow over time with prolonged UV exposure.

- Biological: Neither microorganisms nor moth larvae attack nylon.

- Electrical: High insulating properties lead to static charges.

- Flammability: Burns slowly. Additives can be utilized to enhance flame retardancy.

Uses of Nylon

Nylon has many uses. In the military, it’s used for tents, uniforms, bags, and ropes thanks to it being durable, and heat- and chemical-resistant. Because of nylon's durability, lightweight nature, and resistance to heat and chemicals, it can even be used to make machine parts such as screws, nuts, and bolts. In addition, nylon is often used in the electronics industry for items such as circuit boards and electrical cords.

In some instances it is used as a replacement for metal parts for its strength but flexible nature, so it can be used for certain tools that need to behave in a way that metal simply cannot. As it has good chemical resistance and can survive sterilization, nylon is ideal for use in the medical industry for things like catheters, bandages, hospital beds, walkers, and syringes.

How Xometry Can Help

We hope you have a clearer idea of what nylon is and how it can be used in your projects. If you want to start utilizing nylon, Xometry offers multiple manufacturing options to help you get started. For example, we can 3D print prototypes from nylon powders or filaments, we can cut and machine components from it, or injection mold with it for mass-produced products. You can get started today by uploading your designs to the Xometry Instant Quoting Engine®!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.