Manufacturing materials put up with a lot of different stresses—the engineering kind, that is. From tensile to compressive to shear stress and many more in between, they show the strength of materials and their point of deformity. But it’s how they react to these forces that matters to designers, manufacturers, and engineers who are aiming to create products and structures that can handle these forces in real-life scenarios. Two such examples of stresses that are important for determining what materials to use are tensile stress and compressive stress, which we’ll explore the differences between.

What Is Tensile Stress?

Tensile stress is all about elongation, and it describes when an applied force stretches the length of a material along the axis of the force. If you’re working with a formula, you can represent tensile stress through this:

stress = F/A

Measurements for this type of stress, and most other kinds, are usually expressed through Pascals (Pa) or through pounds per square inch (psi). While tensile elongates, it’s helpful to see how it compares to compressive and shear forces, too, which you can see in the diagrams below.

How Does a Tensile Stress Work?

When a force is applied to a material that tends to pull the material's atoms apart, the material resists, because the bonds between atoms are so strong. The total stretching force is spread across all the atoms on a cross-sectional plane, all of which are resisting the applied force. The stretching force per unit of cross-sectional area is what we call "tensile stress.

The level of tensile stress at which plastic deformation begins to occur varies depending on the material’s chemical composition, microstructural details, and environmental conditions (such as temperature). These factors largely control a material’s mechanical properties. Stress concentrations due to part geometry can also impact the deformation mechanics of a material.

What Causes Tensile Stress?

Tensile stresses are caused by the dislocation motion of atoms in a material’s microstructure when a force is applied. Dislocation typically happens in the same direction as the applied force.

Where Does Tensile Stress Use For?

Tensile stress has many practical applications that enable the proper function of parts and structures. For example, the cables on a suspension bridge experience tensile stresses as vehicles pass across the bridge decking. The cables must be made of materials able to withstand these planned tensile stresses.

Another example where tensile stress is used for a practical purpose is in the ropes or steel cables in pulleys and cranes. As with the cables of a suspension bridge, these lines must be able to withstand the tensile stresses developed while an object is suspended from it. In both cases, the parts must withstand the applied tensile stress for safe and effective use.

What Is the Importance of Tensile Stress?

It is essential for engineers and designers to understand tensile stress and its effects on different materials so that parts and structures can be properly designed for safe and functional use. Conducting a tensile test in a laboratory to determine the yield stress and ultimate tensile strength of a material is one way engineers and designers can do this. From these values, many other mechanical properties such as: elastic modulus, Poisson’s ratio, and strain hardening characteristics can be determined.

What Are the Benefits of Tensile Stress?

The benefits of testing materials under conditions of tensile stress are listed and described below:

- Determine Tensile Strength: Some materials are preferred over others for a particular application due to their higher tensile strengths. Tensile strength describes the stress at which a material will rupture while yield strength is the stress value at which plastic deformation occurs. High tensile strength means that the material is strong and can be used in structural applications where applied forces tend to elongate or stretch materials.

- Measure Ductility: Ductility can be determined from tensile strength by calculating the slope of the linear portion of a stress-strain curve. High ductility means materials can experience significant deformation before failure. This is highly desirable in numerous applications such as the cables in suspension bridges, structural beams, and more.

- Evaluate Fatigue Resistance: Fatigue resistance is a material’s ability to withstand cyclic or repeated loading. Materials with higher tensile strength and ductility have higher fatigue resistance. Fatigue resistance is desirable in applications with oscillating loads such as bridge crossmembers and aircraft components.

What Are Examples of Tensile Stress?

There are tons of examples that exist in the real world of tensile stress and how it looks. We’ve listed a few to give you a good idea of how it appears:

- Pulling a rubber band apart

- Two people pulling opposite ends a rope away from each other

- A crane cable that’s holding something suspended in the air

- Cables on a suspension bridge while vehicles pass over it

What Is Compressive Stress?

This type of stress could be viewed as the reverse of tensile stress. Rather than elongating a material, compressive stress makes it become more compact, exactly as its name states. It’s also expressed in Pascals or pounds per square inch and it, too, deforms and dislocates the material as force is applied.

How Does a Compressive Stress Work?

Compressive stress is caused by forces that compress or compact a material. The dimensions of a material tend to shrink in the direction parallel to the direction of the compressive force and grow in the directions perpendicular to the application of the compressive load.

As compressive stress is applied, the atoms in the material’s crystal structure are pushed closer together. As atoms in the crystal structure move, they push against other atoms. Since atoms cannot occupy the same space, the displaced atoms tend to move in directions perpendicular to the applied force. This causes the material to bulge, or become thicker, in those directions. As compressive stress increases, buckling failure or the sudden bending or twisting of the material occurs. As with tensile stress, the level of compressive stress at which plastic deformation occurs is the yield stress while the level of stress at failure is the compressive strength.

What Causes Compressive Stress?

Compressive stress is caused by atomic dislocations. The dimensions of a material tend to grow in the directions perpendicular to the direction at which the compressive force is applied. When a compressive force is applied, atoms dislocate around a slip plane or an imaginary plane through the material’s microstructure. The atoms above the slip plane compress while the atoms below the slip plane go into tension. This phenomenon is what causes the “widening” effect when materials are in compression.

Where Does Compressive Stress Use For?

Compressive stress has many practical applications that allow engineers to design structures and parts for safe and effective use. For instance, when it comes to designing structural columns, knowing the compressive strength of a material is essential. With this knowledge, engineers can design structures based on the expected loads to avoid buckling of columns.

What Is the Importance of Compressive Stress?

It is critical for engineers to understand compressive stress and how different materials respond to compressive stresses. The safety and functionality of large structures such as bridges, high-rises, and other buildings are highly dependent on their structural members’ ability to withstand compressive stresses. Conducting a compression test in a laboratory can help determine the yield strength of a material in compression, as well as its ultimate compressive strength, and its buckling characteristics such as Euler’s critical load. These properties then enable engineers to design structures that satisfy an application’s loading requirements.

What Are the Benefits of Compressive Stress?

Some benefits of compressive stress testing are listed below:

- Determine Compressive Strength: Some materials are stronger in compression than in tension.Materials such as concrete and steel, have high compressive strengths, which make them great for applications such as roads, bridges, high-rise buildings, and roller mills used for compressing steel sheets or crushing rocks into small pieces, where compression stresses are common.

- Improved Stiffness: Materials that are stronger in compression than in tension tend to also be stiffer. This makes them suitable for applications where high stiffness is desired, such as in road, bridge, and high-rise construction, but also in furniture.

What Are Examples of Compressive Stress?

There are plenty of examples of this type of stress, too, many of which you’ll come across in everyday life:

- Concrete slabs as flooring in buildings or as sidewalks that deform as people, animals, and machines walk and roll over them.

- Structural columns in buildings that support the weight of every floor

- Furniture items like chairs and couches which compress under the weight of people on top

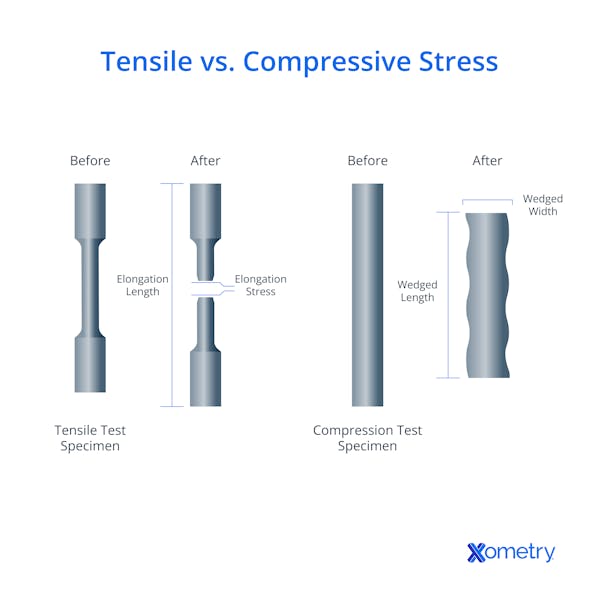

The image below shows a visual comparison of before and after testing and how tensile stress impacts a material versus how compressive stress affects it.

[IMAGE]

Comparing Tensile and Compressive Stress

The main difference between tensile stress and compressive stress is the type of force applied and how the material deforms as a response. With tensile stress, the force stretches and elongates the material, whereas compressive stress presses it together and makes the material more compact.

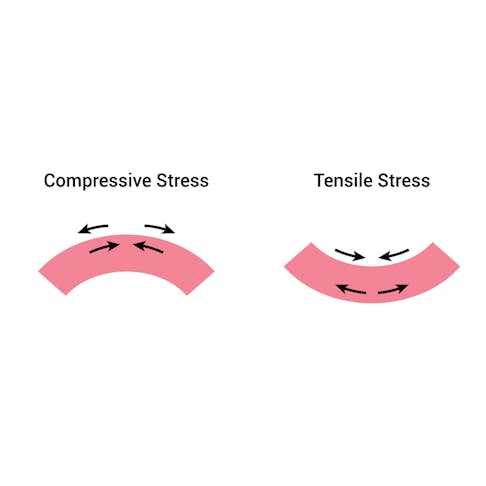

Although they’re different and basically opposite in nature, they can still happen at the same time. It may sound impossible, but it’s a common occurrence in materials and objects that bend. For example, if you bend a pencil until it breaks, you can see both of these stresses in action. As the pencil bends into a U-shape, you can witness compressive stress in the upper portion of the U and tensile stress in the bottom area.

What Is the Significance of Tensile Stress vs. Compressive Stress in 3D Printing?

Both tensile and compressive stresses are important in 3D printing. However, tensile stresses tend to have a larger impact on 3D-printed parts than compressive stresses. 3D-printed plastic parts are often weaker than plastic parts produced by traditional plastic manufacturing techniques such as injection molding or extrusion. This is due to the nature of the 3D printing process, in which parts are constructed layer by layer. 3D-printed parts are weakest in the direction in which the layers build up — the Z-axis. For load-bearing 3D-printed parts, it is a good practice to 3D-print parts in such a way that loads are applied perpendicularly to the Z-axis rather than parallel to it to maximize the amount of tensile stress the part can withstand.

How Is Tensile and Compressive Stress Determined?

Tensile and compressive stresses can be determined using the same equation: the general equation for engineering stress. The equation for engineering stress is shown below:

=FA

Where:

- σ = engineering stress (Pa or psi)

- F = applied force (N or lbf)

- A = cross-sectional area on which the force is applied

Stress is commonly expressed in units of Pascals (Pa) or pounds per square inch (psi). If both the force and cross-sectional area are known, it is easy to calculate the tensile or compressive stress.

How Do Tensile and Compressive Stresses Affect Material Behavior?

Both tensile and compressive stresses affect material behavior. The atoms making up the material attempt to resist attempts to either pull them apart or push them closer together. Tensile and compressive stresses cause atoms in the material’s microstructure to deform and dislocate. As this response occurs, atoms in the microstructure attempt to maintain their interrelationships (elastic deformation). After the stress becomes too great, the atoms can no longer maintain their relationship, and plastic deformation begins. Once plastic deformation begins, elongation or compression due to the applied force becomes permanent. Beyond the physical changes in the material’s microstructure due to excess tensile or compressive stresses, increased susceptibility to corrosion is possible due to the increase in lattice and surface energy.

Frequently Asked Questions About Tensile and Compressive Stress

Can Tensile and Compressive Stress Occur Together?

Yes, tensile and compressive stress can occur together. This is commonly observed in parts that are subjected to bending. Bending a pencil until it breaks is a great example to illustrate these phenomena. Imagine an imaginary line that runs along the entire length of the pencil. When held at both ends and pushed down at a point in the middle, the pencil forms a U-shape, with the middle of the “U” being forced below its original position. Near the bottom of the U, the upper surface of the pencil experiences compressive stresses, while the bottom surface of the pencil experiences tensile stresses.

Is Tensile Stress More Important Compared to Compressive Stress?

It depends on the stress environment in service. For many applications, only tensile stresses need to be considered, while for others, only compressive stresses are important. However, most products and structures operate in complex stress environments, requiring consideration of the effects of both tensile and compressive stresses. When it comes to tensile stress vs. compressive stress, engineers and designers should carefully consider the effects of both. By calculating and analyzing the effects of both types of stresses, engineers can ensure that they produce parts and structures that can tolerate the stresses that will be encountered in service and will not fail or collapse.

Is Compressive Stress Higher than Tensile Stress?

Yes, applied compressive stress levels can often be higher than applied tensile stresses, since some materials (such as concrete) tend to be stronger in compression than in tension. However, applied compressive stresses are not inherently larger than applied tensile stresses. Various factors such as loading, part geometry, and material properties can affect the allowable magnitudes of applied tensile and compressive stresses. For instance, concrete can withstand high compressive stresses, but is weak when tensile stress is applied.

How Xometry Can Help

Whether you’re working with objects made of materials that are frequently exposed to compressive stress or tensile stress, our instant service quotes can help you find the right process, from 3D printing to CNC machining.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.