Before the late 18th century, strong materials certainly existed, but we were in for a surprise when tungsten came onto the scene, overshadowing all other metals in this respect. As the heaviest known engineering metal, tungsten has earned the crown for strength, weight, and conductivity. Due to its desirable characteristics, we at Xometry and our customers have worked together to create custom parts from the material.

When you’re on the market for a material that can put up with immense wear and tear and extreme temperatures, tungsten will rise to the challenge. If you’re interested in learning more about this metal, read on to get an understanding of what tungsten is made of, how it works across industries, and how it’s made.

What is Tungsten?

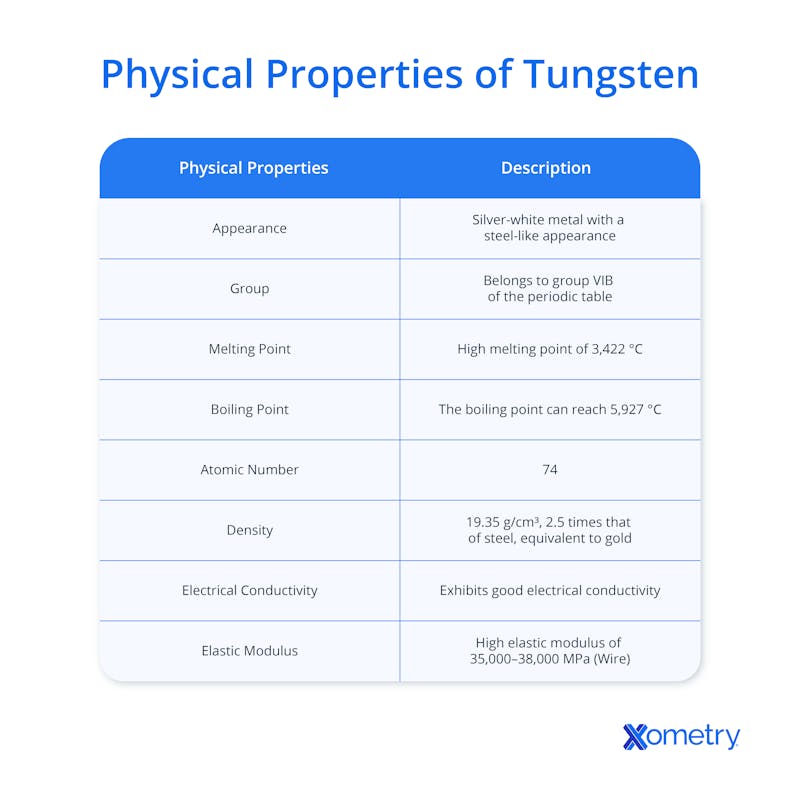

Tungsten is a metal, and you’ll find it on the Periodic Table of Elements, under the symbol W and atomic number 74. Originally called wolfram, tungsten got its new name later, derived from mashing the words for heavy stone in Swedish (tung and sten) into one, which is quite a fitting name. The first name was in honor of one of the ores tungsten is found in.

Engineers and manufacturers love tungsten for its extremely high melting point, 3,422°C, and impressive tensile strength. Although you might be most familiar with tungsten’s block form, which is light to medium gray, in its purest form, it’s actually bright white.

Chemical Formula and Composition

The type of tungsten we know and work with isn’t just tungsten alone. When it hails from scheelite ores, it’s known as calcium tungstate, which has the formula (CaWO4). When you find it in wolframite ores, it’s considered iron-manganese tungstate (Fe,Mn)WO4.

| Chemical Properties | Description |

|---|---|

Chemical Properties Acid Resistance | Description Resistant to nitric acid, hydrofluoric acid, hydrochloric acid, sulfuric acid, and aqua regia at low temperatures; weakly affected by some acids at elevated temperatures |

Chemical Properties Dissolution in Mixed Acid | Description Quickly dissolves in a mixed acid of hydrofluoric acid and concentrated nitric acid at normal temperatures |

Chemical Properties Reaction with Oxidants | Description Intense reaction with oxidants (NaNO3, NaNO2, PbO2, KClO3) to produce tungstate |

Chemical Properties Alkali Resistance | Description Does not dissolve in alkaline solutions |

Chemical Properties Reaction with Carbon | Description Reacts with carbon at high temperatures to produce tungsten carbide, known for its hardness and wear resistance |

Chemical Properties Combination with Elements | Description Can combine with chlorine, nitrogen, oxygen, fluorine, bromine, iodine, carbon, and sulfur at high temperatures; does not undergo hydrogenation |

Chemical Properties Oxidation in Air | Description Molten alkali in the presence of air can oxidize tungsten to tungstate |

Chemical Properties Dissolution in Mixed Acid | Description Quickly dissolves in a mixed acid of hydrofluoric acid and concentrated nitric acid at normal temperatures |

Chemical Properties of Tungsten

The Origin and Discovery of Tungsten

Brothers Juan José and Fausto Elhuyar, two Spanish chemists, get the credit for discovering tungsten and making it a big name in chemistry and industry. Still, the origin story is slightly more convoluted as tungsten was actually being used hundreds of years before – in China. It was also discovered by a Swedish chemist and German miners, but it wasn’t until the Elhuyar brothers distilled it into its metallic form that it really became a big deal and prominent material.

How It’s Made

You won’t find a hunk of tungsten lying around out in the wild, as it needs to be heated and combined with other elements to become the form that’s used for industrial and manufacturing purposes. First, you need to get the tungsten out of the scheelite and wolframite ores it hides in, and this is done by gravity concentration and crushing, which separates the minerals from the element.

Scheelite and wolframite ores will go through flotation, fine grinding, and even leaching, roasting, and high-tension separation to get tungsten out. If you’re in need of ammonium tungsten paratungstate, acid leaching and autoclave-soda processes are most common. Once you get as pure of a solution as you need or have processed the ores, the tungsten trioxide powder can be heated and turned into its pure metal form.

Applications of Tungsten

There are several ways we’ve taken tungsten and made it workable across industries, covering needs for rockets, oncology, fusion power, and beyond. Here are a few applications you should know about:

1. Electronics

When you’re building circuits, you can use tungsten as the interconnecting material between integrated circuits. It’s lauded for its electrical conductivity and resilience, so it’s a great choice when you require a good signal transfer and smooth sailing with interconnected technologies.

2. Alloys

Tungsten makes for a great mix-in ingredient when you’re making alloys. It’s often thrown in with refractory metals, like molybdenum, to boost their properties and create items such as turbine blades, rocket engine nozzles, and even darts.

3. Fusion Power

This power source works by garnering enough heat from nuclear fusion reactions, and tungsten is an attractive candidate when it comes to assisting the reactors where this takes place. There are a few reasons why scientists and engineers herald tungsten for this purpose, including its high melting point, great thermal conductivity, and low reactivity under neutron irradiation.

4. Medical Applications

The medical industry is one that has found many uses for tungsten. If you’re a doctor, you might find it in gamma radiography and oncology instruments. If you’re working with radioactive materials, tungsten materials can create great containers for holding them. In procedures, you may find a tungsten alloy in the form of a radiation-resistant syringe shield.

5. Nanowires

Like with other electronics, tungsten is a suitable option if you need a material with good conductivity and optical properties. Tungsten can be spun into nanowires that are useful for sensors, electronics, optoelectronics, and energy storage.

6. Military Materials

Tungsten has its place in the military, too, offering several uses when it comes to weaponry for defense. You might discover tungsten that’s used in tungsten-alloy bullets, shrapnel heads, and armor-piercing projectiles.

7. Chemical Applications

You can whip tungsten into solutions and chemical compounds as well, which are found in many industries. The list is varied, and you can find pigments, paints, lubricants, and inks all made with tungsten.

8. Jewelry

You’ll find another modern-day use for tungsten in the jewelry industry. Because it’s stronger than gold, silver, and even titanium, tungsten has proven to be a great material if you’re making rings and necklaces. For these reasons, you’ll also see it used in drill bits, too.

9. Welding

Tungsten plays a vital role in tungsten inert gas (TIG) welding, as you can tell from the name alone. Tungsten is made into a non-consumable electrode that creates the electric arc you use to weld. This type of welding is perfect for you if you’re working on more fragile projects and need extra control.

Advantages and Disadvantages

There are several advantages and disadvantages to be aware of when you’re working with tungsten.

Advantages

- High temperature stability: As far as pure metal goes, tungsten impresses by having the lowest coefficient of thermal expansion, so it will hardly expand when you expose it to extreme heat.

- High density and weight: Tungsten is used for racecar ballasts because its density is 1.7 times higher than lead's.

- Good blend of conductivity and inertness: Tungsten is ideal for use in environments with a lot of electricity or radiation because it won’t react in the same way other chemicals would while still remaining conductive.

- High corrosion resistance: You can use tungsten in industries and environments where it’ll be exposed to water, solvents, and acid without having to worry that it’ll corrode.

- Highest melting point: Amongst its fellow pure metals, you’ll find that tungsten has the highest melting point of all at a whopping 3,422° C.

Disadvantages

- Hard and brittle: There are many ways in which you can make the most of tungsten’s hardness, but with some applications, it’s too hard, brittle, and prone to shattering. One example is that if you have the wrong size tungsten wedding ring, it’s not possible to resize it.

- High density means heavy: Although it may come in handy for ballasts, you might find that tungsten is too heavy for other uses where weight reduction is an important factor.

How Xometry Can Help

Xometry and its global partner network have experience working in a variety of metal materials, including tungsten alloys. We have worked with it to machine critical tungsten components. Although it's not available for automatic quoting like many of our other materials, it doesn't mean you can't get a quote for it!

Start by uploading your 3D CAD file to our Instant Quoting Engine® and select the desired process (e.g., CNC machining). Under the material drop-down options, select "Other" and write in the specific tungsten alloy you're interested in. Once you submit your request, our manufacturing experts will manually review it and be in touch shortly.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.