Polylactic Acid (PLA) is a biodegradable thermoplastic polymer derived from renewable plant-based resources and classified as an aliphatic polyester. PLA forms primarily through ring-opening polymerization of lactide, a cyclic dimer derived from lactic acid, producing linear polymer chains with defined thermal and mechanical behavior. The material exhibits moderate tensile strength, high stiffness, low processing temperature, and a glass transition range near 55°C to 65°C, which establishes performance limitations under heat exposure. PLA undergoes degradation under controlled industrial composting conditions through hydrolytic cleavage into oligomers and lactic acid, followed by microbial metabolism. PLA supports a wide range of applications across manufacturing sectors due to consistent processing behavior and renewable sourcing. Fused deposition modeling enables PLA's use in additive manufacturing applications that require controlled dimensional behavior and smooth surface appearance under calibrated printing conditions. Medical-grade PLA supports biomedical applications through predictable degradation behavior suitable for temporary implants and resorbable medical devices. PLA appears in packaging and disposable products intended for short-life use where plant-based plastics replace petroleum-derived materials within managed waste systems.

What is PLA?

Polylactic Acid (PLA) is a biodegradable thermoplastic polymer derived from renewable biological resources. PLA is an aliphatic polyester produced through ring-opening polymerization of lactide, a cyclic dimer derived from lactic acid generated by fermenting plant-based sugars (corn starch, sugarcane, cassava). Thermoplastics soften under heat and solidify during cooling, supporting melt-based manufacturing processes. PLA demonstrates biodegradability primarily under controlled industrial composting conditions involving elevated temperature, moisture, and microbial activity, where hydrolytic cleavage of ester bonds reduces molecular weight prior to biological assimilation. PLA serves a broad role in everyday applications that prioritize renewable sourcing and predictable material performance. Common applications include food packaging, disposable containers, consumer product housings, agricultural films, and additive manufacturing materials, including 3D printing filament and rapid prototyping parts. PLA maintains relevance within biomedical and pharmaceutical use cases through controlled degradation behavior and documented biocompatibility, supporting temporary medical products, including resorbable sutures and controlled drug delivery matrices.

What is PLA Made Of?

PLA is made of fermented plant-derived sugars that undergo microbial conversion into lactic acid. PLA is derived from renewable agricultural feedstocks that supply starch or sucrose, with corn starch and sugarcane serving as primary raw material sources alongside other carbohydrate-rich plants. Microbial fermentation converts extracted sugars into lactic acid, which functions as the fundamental chemical precursor for PLA synthesis. PLA production proceeds through the oligomerization of lactic acid followed by catalytic depolymerization to form lactide, a cyclic dimer intermediate. Polymer formation occurs through ring-opening polymerization of lactide, producing long-chain aliphatic polyester molecules with repeating ester linkages. PLA achieves consistent thermal and mechanical properties through controlled molecular weight distribution, stereochemical configuration, and reaction conditions during polymer synthesis.

How is PLA Made?

PLA is made through a four-step industrial production process that converts plant-derived carbohydrates into a thermoplastic polymer. First, process renewable agricultural feedstocks (corn starch, sugarcane, other starch-rich plant sources) through milling and hydrolysis to release fermentable sugars for downstream handling. Second, ferment the extracted sugars using microbial activity to produce lactic acid, which establishes the primary chemical precursor required for polymer synthesis. Third, convert lactic acid through dehydration and oligomerization into low molecular weight prepolymers, followed by catalytic depolymerization to generate cyclic lactide intermediates under controlled thermal and pressure conditions. Lastly, polymerize purified lactide through ring-opening polymerization inside industrial reactors to form long-chain aliphatic polyester structures with repeating ester linkages, where controlled molecular weight distribution and stereochemical composition define the final thermal and mechanical characteristics of PLA.

Is PLA made of Plastic?

Yes, PLA is made of plastic. PLA qualifies as plastic because PLA functions as a thermoplastic polymer that softens under heat and solidifies during cooling, aligning with the standard industrial definition of plastics used in manufacturing and product design. PLA differs from petroleum-derived plastics because PLA originates from plant-derived carbohydrates and relies on renewable biological feedstocks rather than fossil fuel sources. The bio-derived thermoplastic is used as an alternative to petroleum-based plastics. PLA exhibits degradability primarily under controlled industrial composting environments involving elevated temperature, moisture, and microbial activity, where hydrolytic cleavage reduces polymer chain length before biological assimilation. PLA maintains mechanical performance suitable for packaging, consumer goods, and additive manufacturing applications while providing a plant-based plastic option aligned with sustainability-focused material selection.

Is PLA Made From Corn?

Yes, PLA is made from corn in many commercial production systems. PLA originates from fermentable sugars extracted from corn starch, where microbial fermentation converts sugars into lactic acid that serves as the chemical precursor for PLA polymer synthesis. PLA production relies on renewable agricultural feedstocks rather than petroleum, placing PLA within the category of plant-based plastics used as alternatives to fossil-derived materials. Composting PLA requires controlled industrial composting conditions that maintain elevated temperatures, regulated humidity, and active microbial populations. PLA degradation proceeds through hydrolytic cleavage of ester linkages that reduces polymer molecular weight into oligomers and lactic acid, followed by microbial assimilation into carbon dioxide and water. PLA does not readily degrade in natural soil, freshwater, or marine environments, which limits unmanaged environmental breakdown and requires appropriate industrial composting infrastructure for effective end of life processing.

What are the Applications of PLA?

The applications of PLA are listed below.

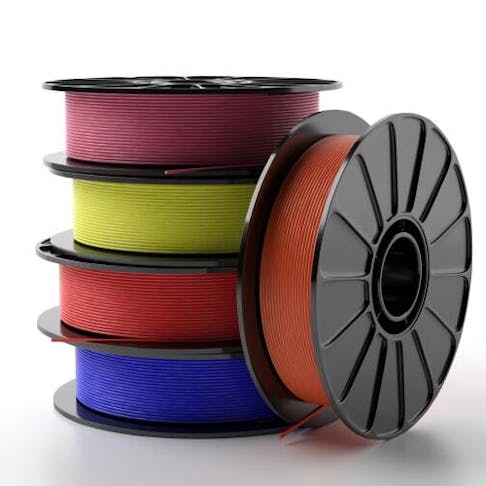

- 3D Printing: PLA functions as a primary filament material in fused deposition modeling due to relatively stable melt flow, low processing temperature, and predictable dimensional behavior during layer deposition. PLA supports prototyping, educational models, and decorative end-use components produced through desktop and industrial additive manufacturing systems.

- Medical Implants: Medical-grade PLA supports temporary biomedical applications through its degradation into biocompatible lactic acid, which is safely metabolized by the human body. PLA appears in resorbable sutures, fixation devices, tissue scaffolds, and drug delivery matrices, where hydrolytic degradation aligns with biological healing timelines.

- Packaging: PLA serves as a plant-based plastic used in food containers, cups, trays, and transparent films intended for short term use. PLA packaging targets compostable product lines for managed waste systems that support industrial composting infrastructure.

- Biodegradable Films: PLA forms thin films applied in agricultural mulch films, compostable bags, and disposable wraps intended for controlled degradation under industrial composting conditions. PLA film applications aim to reduce long term material persistence compared to conventional petroleum-based plastics.

- Consumer Products: PLA appears in disposable tableware, cosmetic containers, household goods, and promotional items that prioritize renewable feedstocks and predictable molding behavior during injection molding and thermoforming processes.

- Industrial Prototyping: PLA supports rapid design validation through visual prototypes, functional mockups, and low-load mechanical components produced during early-stage product development cycles.

What is Polylactic Acid Used For?

The uses of Polylactic Acid are listed below.

- Biodegradable Plastic Production: Polylactic Acid functions as a bio-based thermoplastic material used in compostable plastic products for short-life applications within managed industrial composting systems. Polylactic Acid supports molded components that require predictable stiffness and controlled degradation behavior under elevated temperature and humidity conditions.

- 3D Printing Filaments: Polylactic Acid operates as a standard filament material in fused deposition modeling systems due to stable melt flow, relatively low processing temperatures, and predictable dimensional behavior during extrusion. Polylactic Acid supports prototyping, educational models, and decorative components produced through additive manufacturing workflows.

- Medical Devices: Medical-grade Polylactic Acid supports temporary biomedical products that rely on controlled degradation inside the human body. Polylactic Acid appears in resorbable sutures, fixation pins, tissue scaffolds, and drug delivery carriers, where hydrolytic chain scission aligns with medical recovery timelines.

- Packaging: Polylactic Acid functions in food containers, cups, trays, and transparent films intended for single-use or short-duration storage. Polylactic Acid packaging targets managed waste systems that support industrial composting rather than long-term durability or repeated reuse.

- Agricultural Films: Polylactic Acid forms films used in agricultural applications that require controlled material recovery after use. Polylactic Acid agricultural films are intended for collection and processing within industrial composting infrastructure rather than uncontrolled environmental degradation.

What are the Properties of PLA?

The properties of PLA are listed below.

- Density: PLA maintains a density range of 1.24 to 1.27 grams per cubic centimeter, which is higher than many petroleum-derived plastics and reflects its aliphatic polyester molecular structure.

- Melting Point: PLA presents a melting temperature between 130°C and 180°C, depending on molecular weight and stereochemical composition, supporting relatively low temperature processing in extrusion and molding operations.

- Glass Transition Temperature: PLA exhibits a glass transition temperature near 55°C to 65°C, marking the transition from rigid glassy behavior to softened rubber-like behavior under heat exposure.

- Tensile Strength: PLA demonstrates tensile strength values ranging from 50 to 70 megapascals, indicating comparatively high strength among biodegradable thermoplastics.

- Flexibility: PLA displays low inherent flexibility and relatively brittle behavior under impact loading, with a typical elongation at break of 2% to 10%, which is significantly lower than polyethylene-based or elastomeric plastics.

- Biodegradability: PLA undergoes degradation under controlled industrial composting environments through hydrolytic cleavage of ester bonds that reduce polymer molecular weight into oligomers and lactic acid, followed by microbial metabolism into carbon dioxide and water.

- Thermal Stability: PLA shows moderate thermal stability during processing but experiences rapid loss of structural rigidity when exposed to sustained temperatures above the glass transition range, which limits high-temperature service applications.

What is the Difference Between PLA and PLA Plus?

The difference between PLA and PLA Plus lies in the formulation strategy used to modify mechanical and thermal behavior. Conventional polylactic acid formulations differ from manufacturer-specific PLA-based materials engineered through proprietary additive systems to adjust strength, toughness, and print performance. Standard formulations provide high stiffness and exhibit brittle fracture behavior with limited thermal resistance near the glass transition temperature. The improved formulations deliver increased impact resistance, greater ductility, and improved interlayer adhesion compared to standard material grades. Increased durability results from additive systems that influence polymer chain interaction and reduce crack propagation under mechanical stress. Standard grades offer simpler processing and lower cost, while improved formulations support functional additive manufacturing with higher toughness and moderate heat resistance compared to standard thermoplastics, such as PLA and PLA Plus.

Is PLA Plus Biodegradable?

Yes, PLA Plus retains biodegradability under industrial composting conditions when the specific formulation complies with recognized industrial composting standards. PLA Plus remains based on polylactic acid chemistry, which enables degradation through hydrolytic cleavage of ester bonds under sustained heat, controlled humidity, and active microbial conditions present in industrial composting systems. Polymer chain scission reduces molecular weight into oligomers and lactic acid, followed by microbial metabolism into carbon dioxide and water. PLA Plus does not degrade efficiently in natural soil, freshwater, or marine environments due to insufficient temperature and moisture required to initiate ester bond cleavage. PLA Plus formulations containing toughness or heat-resistant additives degrade at variable rates depending on additive chemistry, reinforcing reliance on managed industrial composting systems for effective end of life processing of PLA+ Filament.

How is PLA Used in 3D Printing?

PLA is used in 3D printing by fused deposition modeling, where PLA filament feeds into a heated extruder, melts, and deposits material layer by layer to form solid objects. PLA printing typically operates with nozzle temperatures between 190°C and 220°C, while bed temperatures range from ambient to about 60°C depending on PLA formulation, printer hardware, build surface, and adhesion strategy. PLA exhibits consistent melt flow at relatively low temperatures, supporting smooth extrusion and a lower tendency toward warping compared to higher temperature thermoplastics. The bonding between PLA layers improves when extrusion temperature, print speed, and first layer parameters promote polymer diffusion and thermal contact between deposited layers. PLA print quality depends on cooling control and slicer configuration that maintain dimensional accuracy and surface definition. Active part cooling commonly follows the initial layers to accelerate solidification and preserve fine details. PLA printing performance improves with moderate print speeds, calibrated retraction settings, stable filament feed, consistent layer heights, and dry storage conditions that limit moisture-related extrusion defects during 3D printing.

Is PLA Compatible with 3D Printing?

Yes, PLA is compatible with 3D printing and ranks among the most used filaments in fused deposition modeling. PLA supports interlayer bonding through consistent melt flow and predictable solidification behavior when extrusion temperature and print parameters permit adequate thermal diffusion between successive layers. PLA printing operates within nozzle temperature ranges of 190°C to 220°C, while bed temperatures remain low or optional due to low thermal shrinkage and a relatively low glass transition temperature. Entry-level and general-purpose printing remain popular with PLA due to its ease of processing and predictable dimensional behavior under controlled conditions. PLA extrudes smoothly at lower temperatures than many engineering thermoplastics, which reduces thermal stress on printed parts and printer components. PLA supports clean surface finish and consistent extrusion when printer calibration, cooling control, and slicer configuration remain properly managed, reinforcing broad compatibility and adoption in 3D printing workflows.

What are the Best PLA Settings for 3D Printing?

The best PLA settings for 3D printing are listed below.

- Use nozzle temperature. Set the nozzle temperature between approximately 190°C and 220°C to maintain stable melt flow, consistent extrusion, and reliable interlayer bonding.

- Choose bed temperature. Set the build plate between ambient temperature and about 60°C to support first layer adhesion, with reduced edge lifting primarily resulting from PLA low thermal shrinkage.

- Apply print speed. Use moderate print speeds commonly ranging from 40 to 60 millimeters per second, with optimal values dependent on printer kinematics, nozzle diameter, and cooling capability.

- Select layer height. Apply layer heights between approximately 0.12 and 0.28 millimeters depending on nozzle diameter and resolution requirements, where lower values improve surface detail and higher values reduce print time.

- Enable cooling settings. Use active part cooling after the initial layers to accelerate solidification, preserve fine features, and limit stringing or sagging.

- Adjust retraction parameters. Apply calibrated retraction distance and speed to reduce filament oozing during travel moves while maintaining consistent material flow through the nozzle.

What are the Advantages of PLA?

The advantages of PLA are listed below.

- Ease of Printing: PLA prints with stable extrusion and predictable melt flow at relatively low temperatures, which simplifies setup under properly calibrated printing conditions across common fused deposition modeling systems.

- Low Warp: PLA exhibits minimal thermal contraction during cooling due to low shrinkage characteristics, which limits warping, edge lifting, and dimensional distortion during part formation.

- Good Surface Finish: PLA supports smooth surface quality and sharp detail resolution when extrusion temperature, cooling behavior, and layer height remain properly controlled during printing.

- Biodegradability: PLA undergoes degradation under controlled industrial composting conditions through hydrolytic cleavage of ester bonds into oligomers and lactic acid, followed by microbial metabolism into carbon dioxide and water.

- Low Odor: PLA emits minimal odor during extrusion compared to many petroleum-derived thermoplastics, which improves suitability for enclosed or indoor printing environments.

- Renewable Sources: PLA originates from plant-derived carbohydrates sourced from agricultural feedstocks, which reduces reliance on fossil-based raw materials.

From a design engineering perspective, selecting PLA requires a strict focus on the part's operating environment, as the low heat deflection temperature can lead to structural failure in even moderately warm conditions. Effective material selection hinges on balancing PLA's high surface hardness and stiffness against its limited impact resistance, often requiring geometry-specific optimizations to compensate for the polymer's inherent brittleness.

What are the Disadvantages of PLA?

The disadvantages of PLA are listed below.

- Brittleness: PLA exhibits low impact resistance and limited elongation at break, which increases susceptibility to cracking or fracture under sudden mechanical loading.

- Low Heat Resistance: PLA softens near the glass transition temperature around 55°C to 65°C, which restricts use in warm environments or applications exposed to sustained heat.

- Limited Chemical Resistance: PLA shows reduced resistance to certain solvents and chemical agents, which accelerate surface degradation and loss of mechanical integrity.

- Lower Durability Compared to ABS or PETG: PLA demonstrates reduced long term toughness and thermal stability relative to ABS or PETG, which limits performance in parts that require flexibility, impact strength, or exposure to elevated temperatures and outdoor environments.

Is PLA less Durable than ABS?

Yes, PLA is less durable than ABS. PLA exhibits higher stiffness and surface rigidity, while showing lower impact resistance, reduced elongation at break, and increased brittleness under mechanical stress. ABS demonstrates superior toughness and higher heat resistance compared to PLA, supporting longer service life in functional parts subjected to mechanical and thermal loading. PLA softens near the glass transition temperature around 55°C to 65°C, which limits durability in warm or mechanically demanding environments. ABS maintains structural integrity at higher temperatures and absorbs impact energy more effectively, reducing crack initiation and fracture during use. PLA remains suitable for visual models and low-load functional applications, while ABS supports components that require greater impact resistance, thermal stability, and long-term mechanical durability in the PLA vs. ABS comparison.

Does PLA Filament Absorb Moisture?

Yes, PLA Filament absorbs moisture because polar ester groups within the polymer backbone attract water molecules during storage in humid conditions. Moisture presence triggers hydrolytic chain scission during extrusion, which produces bubbling, stringing, surface roughness, and reduced mechanical strength in printed parts. PLA Filament moisture absorption disrupts melt flow stability, which affects print consistency and dimensional accuracy during fused deposition modeling. PLA Filament exposed to humidity requires controlled storage conditions to limit water uptake, since absorbed moisture accelerates polymer chain scission when heated during the printing process.

What are the Different Types of PLA?

The different types of PLA are listed below.

- Standard PLA: Standard PLA represents conventional polylactic acid formulations for stable processing and smooth surface appearance. Standard PLA emphasizes stiffness and low processing temperature, supporting prototyping and visual models under controlled printing conditions.

- PLA Plus: PLA Plus refers to manufacturer-specific PLA formulations engineered with proprietary additive systems that improve toughness, impact resistance, and interlayer adhesion relative to standard PLA. PLA Plus targets functional printing applications that require improved mechanical performance compared to conventional PLA.

- Blended PLA: Blended PLA combines polylactic acid with other biodegradable or synthetic polymers to modify flexibility, thermal behavior, or print stability. Blended PLA performance varies based on blend composition and aims to adjust ductility or heat response relative to standard PLA.

- Reinforced PLA: Reinforced PLA incorporates fillers or fibers that increase stiffness, strength, or wear resistance. Reinforced PLA variants support structural components, fixtures, and printed parts that require higher load tolerance and dimensional rigidity.

- Specialty PLA Variants: Specialty PLA includes formulations developed for specific performance objectives, including improved heat resistance through increased crystallinity or annealing, improved transparency, electrical conductivity achieved through conductive fillers, or specialized aesthetic surface finishes. Specialty PLA variants address application requirements beyond general-purpose additive manufacturing.

Which PLA is the Strongest?

The strongest PLA is carbon fiber reinforced PLA when strength is specifically by its high tensile modulus and resistance to elastic deformation under load. Carbon fiber reinforced PLA incorporates chopped carbon fibers into a polylactic acid matrix, which increases stiffness and limits deformation under mechanical loading while increasing brittleness and directional anisotropy. Carbon fiber reinforced PLA suits rigid structural components, fixtures, and brackets where dimensional stability and load bearing stiffness take priority over impact resistance. PLA Plus represents a PLA formulation optimized for balanced mechanical performance rather than maximum rigidity. PLA Plus improves toughness and impact resistance through proprietary additive systems that improve polymer chain interaction and interlayer adhesion. Blended PLA formulations occupy an intermediate position by trading some stiffness for improved ductility, supporting functional parts that require resistance to cracking during repeated handling rather than maximum structural rigidity.

Summary

Xometry provides a wide range of manufacturing capabilities including CNC machining, 3D printing (including PLA 3D printing), injection molding, laser cutting, and sheet metal fabrication. Get your instant quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.