Your most slippery cookware, heated hair tools, and the wire coatings around your home all have a material in common: Teflon. This sleek coating pops up in both household and industrial settings and, because of its lack of friction and thermal and chemical resistance, it gets coated onto quite a lot of products.

What is Teflon?

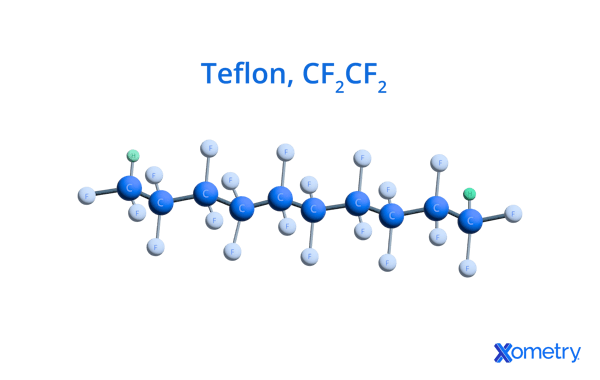

Polytetrafluoroethylene (PTFE) is a fluoropolymer coating that’s usually referred to by its trademark name Teflon—which is much less of a tongue twister. It has a combination of fluorine and carbon atoms that give it unique thermal, mechanical, and chemical advantages.

An employee for DuPont named Roy J. Plunket accidentally created Teflon while trying to invent a different type of refrigerant and, after discovering all of its useful characteristics, it became a popular choice for coating.

What Is the History of Teflon?

Teflon was discovered by accident by Roy J. Plunket in 1938 while working for DuPont. It was discovered while Plunket was producing tetrafluoroethylene gas for testing a new type of refrigerant to potentially replace ammonia and sulfur dioxide. However, after cooling the tanks to -78.5 °C, the gas turned into a white powder. Plunket decided to characterize the material to determine its physical properties, leading to the discovery of Teflon. Teflon was made into a commercial product in 1946.

What Is the Other Term for Teflon?

Teflon is a trademark of Chemours, however, the chemical name for Teflon is PTFE which stands for polytetrafluoroethylene. Rulon® is also a branded PTFE formulation.

What Is Teflon Made Of?

Polytetrafluorethylene’s chemical makeup involves fluorine atoms surrounding carbon atoms in a protective layer. You can see in the image below how these atoms link together and form a molecular structure.

To create PTFE, you’ll need fluorspar, hydrofluoric acid, chloroform, and water. Then they’ll chemically react in a special heated chamber. Once this happens, tetrafluoroethylene is synthesized from the process, which then goes on to get polymerized, leading to the creation of PTFE.

What Are the Properties of Teflon?

Teflon is a go-to choice because of its low friction and high temperature and chemical resistance. We’ve put tables down below that explain the different physical, mechanical, and electrical properties of Teflon.

Here are a handful of some of Teflon’s physical properties worth noting:

| Physical Properties | Values |

|---|---|

Physical Properties Density [g/cm3] | Values 2.07 |

Physical Properties Hardness [Shore D] | Values 57 |

Physical Properties Friction Coefficient [Steel] | Values 0.0646 |

Physical Properties Water Absorption [%] | Values 0.0074 |

Physical Properties Melting Temperature [°C] | Values 325 |

Table Credit: https://matweb.com/

| Mechanical Properties | Values |

|---|---|

Mechanical Properties Ultimate Tensile Strength [MPa] | Values 35 |

Mechanical Properties Yield Strength [MPa] | Values 20.5 |

Mechanical Properties Elongation at Break [%] | Values 306 |

Mechanical Properties Flexural Yield Strength [MPa] | Values 19.6 |

Mechanical Properties Flexural Modulus [GPa] | Values 0.672 |

Mechanical Properties Compressive Yield Strength [MPa] | Values 10.2 |

Mechanical Properties Charpy Impact Strength [J/cm2] | Values 1.76 |

Table Credit: https://matweb.com/

| Electrical Properties | Values |

|---|---|

Electrical Properties Electrical Resistivity [Ω.cm] | Values 8.68E+17 |

Electrical Properties Surface Resistance [Ω] | Values 4.48E+17 |

Electrical Properties Dielectric Constant | Values 2.39 |

Electrical Properties Dielectric Strength [kV/mm] | Values 58.7 |

Electrical Properties Dielectric Loss Index | Values 0.0001 |

Electrical Properties Arc Resistance [sec] | Values 346 |

Table Credit: https://matweb.com/

What Are the Chemical Properties of Teflon?

Teflon offers some impressive chemical properties that give it an upper hand in certain situations and make it such a good coating for different types of products. It’s resistant to acids, bases, solvents, hydrocarbons, oils, fuels, water, and alcohol—making it one of the most chemically resistant choices out there. That being said, it doesn’t do so well when it’s up against alkali metals, gaseous fluorine, chlorine trifluoride, and oxygen difluoride.

What Are the Optical Properties of Teflon?

As far as optical properties go, there is a version of Teflon (Teflon AF) that can have a high level of optical clarity and great UV stability, which is helpful for some applications and manufacturing needs.

What Are the Types of Teflon?

There are a few variations of PTFE out there, and here are six of the most common to know about:

1. Granular PTFE

This Teflon is a powder and it usually bolsters rods or tubes, which will be made through compression molding and then sintered. It is created through suspension polymerization.

2. Fine Powder PTFE

Also a powder and sometimes called emulsion-grade PTFE, this version of Teflon is finer in texture and made with the help of emulsion polymerization. The paste-like form of it gets extruded into wires, tubes, films, and fibers.

3. Micro Powder PTFE

Made of even finer particles, Teflon of this kind comes to be through direct polymerization. It can go through milling and grinding, as well, and it helps lessen friction on the surfaces that will be subject to wear and tear and flames.

4. Dispersion PTFE

This style of Teflon has its particles dispersed in a fluid, which makes it a great choice for coatings that you’ll need to apply on things like fabric or cookware. The liquid format makes it easy to cling onto surfaces and provide the qualities people want from Teflon.

5. Film PTFE

This is a PTFE found in film or tape form made by shaving down a thick, solid bar of PTFE. It’s a good choice for helping stick different materials together.

6. Expanded PTFE

Made up of tiny fibers, this Teflon type usually is used for gaskets, mostly due to its top-notch thermal and chemical resistance.

What Are the Applications of Teflon?

Teflon can be found in so many products and components, so we’ve listed out a few examples:

- Bearings and seals

- Electrets

- Chemically inert liners for storage tanks and pipes

- Tensioned membrane structures

- Composites

- Musical instrument coatings, like for guitar strings and wind instruments

- Lubricants between surfaces

- Kitchenware as coatings for pots and pans

- Medical products like tubes, catheters, and pumps

- Coatings for automotive gaskets, wires, seals, and bushings

- Coatings on spacecraft and rovers

- Insulators for electric wires

Is It Safe To Use Products With Teflon?

PTFE is chemically inert and is often used for coating cooking surfaces. It is safe to be used in contact with food. However, if overheated, the fumes from Teflon-coated cookware can cause a flu-like sickness called polymer fume fever.

What Are the Advantages of Teflon?

There are a few benefits you’ll find in working with Teflon, including the following

- Good thermal resistance: Teflon can handle temperatures of up to 325 ℃ and extremely cold temperatures as low as 275 ℃.

- Low friction: Teflon can take the prize for having the lowest friction out of almost any other material out there.

- Chemically inert: While it can’t handle some chemicals, for the most part, Teflon is highly resistant and inert to a wide range.

What Are the Disadvantages of Teflon?

There are also a handful of characteristics that can make it limiting or difficult to work with Teflon:

- Nonstick: Although this is a perk for things like cookware, it’s not ideal when you need to bond Teflon to another surface.

- High thermal expansion: When compared to other plastics, you’ll find Teflon expands more than most.

- Poor radiation resistance: Although it’s chemically resistant, radiation is one such thing that’ll break down Teflon.

- Not biodegradable: Unfortunately, Teflon isn’t a biodegradable material, but it is recyclable.

Frequently Asked Questions About Teflon

Are Teflon Biodegradable?

No, Teflon is not biodegradable and will not break down under natural conditions as it has high thermal, chemical, and UV (ultraviolet) resistance. Teflon can, however, be recycled.

Are Teflon Water Soluble?

No, Teflon is resistant to moisture ingress and will not dissolve in water.

Are Teflon Elastic?

Yes, however, this is only true at low elongations.

Is Teflon a Type of Polymer?

Yes, Teflon is a fluoropolymer. Its molecular chain consists of a carbon backbone with tightly packed fluorine atoms around it.

What Are the Differences Between Teflon and Plastic?

Teflon is a type of plastic, specifically, it is a thermoplastic polymer.

What Are the Differences Between Teflon and Metal?

Teflon is a polymer made up of repeating carbon and fluorine molecules. Metal typically has a crystalline structure and is made up of tightly placed metallic elements like iron and aluminum for example.

What Are the Differences Between Teflon and Silicone?

Both silicone and Teflon are polymers with high thermal resistance. However, silicone has a relatively high friction coefficient compared to Teflon and is also a thermosetting polymer compared to Teflon—a thermoplastic polymer.

What Are the Differences Between Teflon and Nylon?

Teflon and nylon are both thermoplastic polymers. Nylon has a relatively low friction coefficient compared to most other polymers but is still higher than Teflon. Nylon also has a lower thermal and chemical resistance when compared to Teflon. However, nylon is easier to process.

How Xometry Can Help

We offer services that work with Teflon, including Teflon CNC machining. We also have plenty of other manufacturing and processing options that involve plastics and polymers, like plastic 3D printing, plastic extrusion, and nylon CNC machining.

Copyright and Trademark Notices

- Teflon® is a trademark of the Chemours Company

- Rulon® is a trademark of the Dixon Industries Corporation

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.