Acrylic is a widely used thermoplastic and is favored for its optical clarity. It is a low-cost alternative to transparent polycarbonate. Acrylic laser cutting and engraving are relatively easy on low-powered CO2 laser cutters.

There are two types of acrylic: cast and extruded. Cast acrylic is better suited for engraving, and extruded acrylic is best for cutting. These types of acrylics are more commonly known by the trade names Perspex® and Plexiglas®.

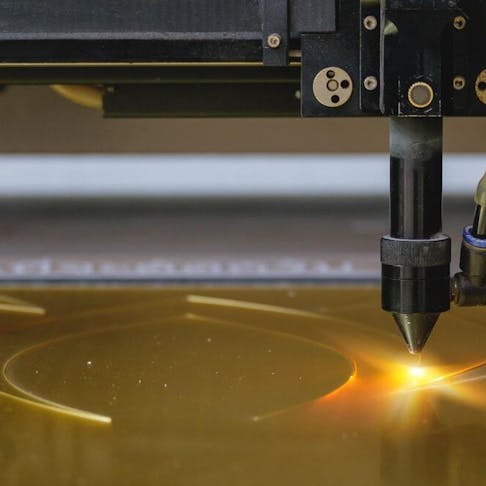

This article will discuss what acrylic is, how to laser cut and engrave it, what steps to take when laser cutting it, and what the optimal acrylic laser cutting settings are. Figure 1 below shows a laser-cut acrylic keypad assembly made by Xometry:

What is Acrylic?

Acrylic is a thermoplastic that is naturally transparent but can also be colored. It can refer to any material that contains acrylic acid or acrylates. Acrylic is often used as a shatterproof glass replacement due to its optical clarity and strength. It is brittle and will crack rather than bend. Acrylic is known by different trade names, such as Plexiglas® or Perspex®. It is sold as cast or extruded acrylic sheets. Various additives can also be added to acrylic to improve various properties such as UV resistance, electrostatic dissipation, and abrasion resistance.

Acrylic has many uses for Xometry customers and others that take advantage of its low cost, optical clarity, strength, and ease of use. Some typical applications are listed below:

- Awards

- Lenses

- Marketing signs

- Artistic products

- Furniture

- Glass replacement

Acrylic plastics are generally broken down into cast acrylic and extruded acrylic. Extruded acrylic comes in sheet form, either transparent, semi-transparent, or opaque, and is relatively flexible. Cast acrylic is also cast into sheets and produces acrylic with excellent clarity, at the expense of increased brittleness. Cast acrylic is best for laser engraving as it produces a frosty white color when engraved which is sometimes desired if filling an area.

Types of Acrylic

Acrylic plastics are generally broken down into cast acrylic and extruded acrylic. Extruded acrylic comes in sheet form, either transparent, semi-transparent, or opaque, and is relatively flexible. Cast acrylic is also cast into sheets and produces acrylic with excellent clarity, at the expense of increased brittleness. Cast acrylic is best for laser engraving as it produces a frosty white color when engraved which is sometimes desired if filling an area.

How to Laser Cut Acrylic

The basic steps for achieving good quality cut acrylic parts are listed below:

- Select material: For cutting, extruded acrylic is better. Cast acrylic is best for engraving.

- Prepare material: Acrylic sheets are often sold in relatively large sizes. Most entry-level and mid-range laser cutters have relatively small beds, so the acrylic must be cut into smaller sheets before it can be used. This process can be done with a table saw or jigsaw.

- Prepare design: Next, the design file must be prepared. This can be done using laser cutting software which turns images or line drawings into a set of laser instructions for the machine. Make sure the correct settings are used for optimal results. Most software packages have presets for acrylic.

- Cutting: Load the cutting instructions into the laser cutter. Make sure the enclosure is secured and the ventilation system is functional, then begin cutting.

- Finishing: Once the parts have been cut, they can be removed from the machine and post-processed. With the right settings, acrylic parts will have a very smooth cut edge that requires no further processing.

The Laser Cutting Process for Acrylic

The most common type of laser cutter used for acrylic laser cutting is a CO2 laser. This laser works by ionizing a glass tube filled with CO2 gas using a strong electric field. These molecules then release photons of a specific wavelength that bounce back and forth in the tube with the aid of opposing mirrors, one of which is semi-transparent. Once the light reaches a certain intensity, it passes through the transparent mirror and is directed to the cutting head by a set of mirrors. A focusing lens in the cutting head focuses the light into a high-intensity point which melts and vaporizes the acrylic. An air blast system will blow out any melted acrylic from the cut. However, multiple-pass cuts are often preferred to cutting through the material in one step.

Settings for Laser Cutting Different Acrylic Materials

Table 1 below lists some recommended settings for acrylic laser cutting and engraving:

| Material | Power (W) | Speed (mm/s) | Points Per Inch (PPI) | Passes | Depth (in) |

|---|---|---|---|---|---|

Material Cut (Extruded Acrylic) (6 mm) | Power

(W) 100 | Speed

(mm/s) 2 | Points Per Inch

(PPI) 1000 | Passes 1 | Depth

(in) 0.25 |

Material Vector Engraving (Cast Acrylic) | Power

(W) 2 | Speed

(mm/s) 4 | Points Per Inch

(PPI) 1000 | Passes 1 | Depth

(in) 0.005 |

Material Raster Engraving - Shallow (Cast Acrylic) | Power

(W) 22 | Speed

(mm/s) 100 | Points Per Inch

(PPI) 500 | Passes 1 | Depth

(in) 0.002 |

Material Raster Engraving - Deep (Cast Acrylic) | Power

(W) 100 | Speed

(mm/s) 90 | Points Per Inch

(PPI) 500 | Passes 1 | Depth

(in) 0.01 |

Table Credit: https://academics.design.ncsu.edu/

Xometry provides a wide range of manufacturing capabilities including CNC machining, 3D printing, injection molding, laser cutting (including acrylic laser cutting), and sheet metal fabrication. Get your instant quote today.

Copyright and Trademark Notices

- PLEXIGLAS® is a registered trademark of Röhm GmbH.

- PERSPEX® is a registered trademark of ICI Chemicals & Polymers Limited.

- Glowforge® is a trademark of Glowforge Inc. CORPORATION DELAWARE.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.