With its ability to make parts with elaborate designs, laser cutting has quickly become one of the most common manufacturing methods used today by both hobbyists and industrial professionals. It’s versatile and can cut, engrave, and etch lots of different materials, including organic leather, wood, paper, non-organic metals, plastics, and… copper!

The way a material reflects light and its melting and boiling points play a huge role in how well it can be laser cut. If a material reflects a lot of the laser’s energy, it can be a pain to cut. Also, the amount of time it takes for a material to melt or turn to vapor ultimately dictates how hot the laser needs to get. A highly reflective material can also damage the laser optics equipment.

Copper and its alloys are notorious for being really difficult to cut because of how much light they reflect, especially infrared radiation (over 95%!) when in a solid state. It makes the process unstable and hard to control—but it’s not impossible! You just need the know-how. We got our in-house experts on the case and picked their brains for the best tips and tricks for successfully laser-cutting copper.

What Is the Definition of Copper Laser Cutting?

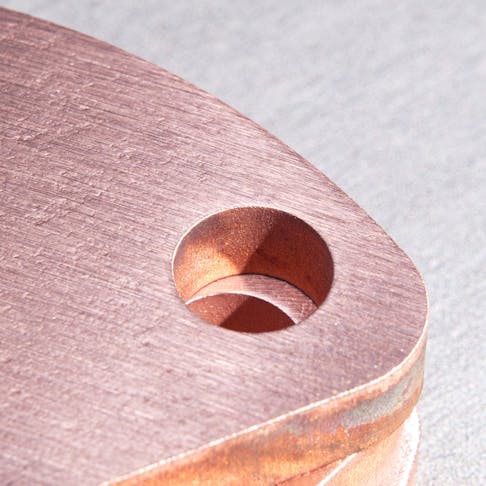

When cutting a copper sheet or workpiece using a laser cutter, you’ll ideally want to use one with a fiber laser because copper can easily absorb the blue, violet, and ultraviolet wavelengths from these. Below, you can see an example of copper that’s been laser-cut.

There are three main types of laser cutting—fusion, flame, and sublimation (vaporization)—but only flame cutting can be used on copper. Flame cutting uses oxygen, which creates a chemical exothermic reaction that releases energy to its surroundings. It heats up the workpiece and forms a copper oxide. The magic is all in this oxide; it makes the material’s surface much less reflective and helps it better absorb energy. Since flame cutting is likely to leave some burrs behind, you’ll need to do some post-processing work if your piece needs to be pretty.

What Is Copper Laser Engraving?

Copper laser engraving is the process of making shallow cuts into a copper workpiece to make elaborate patterns and designs. Copper is widely used for laser engraving because it is a low-cost, readily available material. When engraved using a CO2 laser, copper workpieces must first be coated with a metal marking spray or paste to prevent reflection and to force the workpiece to absorb the energy from the laser. Using a fiber laser avoids the need for such a coating.

What Issues Most Frequently Arise When Copper Is Laser Cut?

The issues that most frequently arise during copper laser cutting are listed below:

- Copper exhibits low absorption and high reflectivity of infrared wavelengths, leading to inefficient laser cutting.

- Copper’s high reflectivity can damage laser optics equipment.

- Copper reflects over 95% of infrared radiation when in its solid state. This makes the cutting process unstable and difficult to control. It absorbs more energy from infrared wavelengths as it warms up and becomes molten — making laser cutting easier and more efficient.

To counter the difficulty surrounding copper laser cutting, users have two options. Firstly, users can opt to use a fiber laser that emits shorter wavelengths than infrared to laser cut copper. While fiber lasers are preferred for laser cutting copper, they are much more costly than CO2 lasers and may not be an economical choice for some users. The second option is to coat copper workpieces with a metal marking spray or paste to reduce the reflectivity of the copper and force the workpiece to absorb energy from the laser.

Which Type of Laser Cutting Is Employed When Cutting Copper?

There are three main types of laser cutting materials: flame cutting, fusion cutting, and sublimation cutting (also known as vaporization cutting). The best type of laser cutting method to use depends on the workpiece material. The three types are described in more detail below.

- Flame Cutting: Oxygen is used to assist the laser cutting process. It creates an exothermic reaction to assist in heating the workpiece and forms oxides that reduce material reflectivity. Oxygen also increases the amount of energy available to the workpiece.

- Fusion Cutting: An inert gas, like nitrogen, is used to force molten material from the kerf. This helps produce clean, smooth cuts.

- Sublimation Cutting (Vaporization Cutting): The material is heated so rapidly that minimal melting occurs, and instead, the material is directly vaporized. Shield gas is used with this cutting process to prevent the workpiece edges from oxidizing.

Flame cutting is the best technique for copper laser cutting because it heats the workpiece and causes oxidation on the surfaces of the part near the cut. The presence of copper oxide makes the workpiece less reflective and allows it to absorb energy from the laser more efficiently. Post-processing is typically required to achieve desired dimensions and appearance because flame cutting tends to leave burrs on the part

What Are the Elements in Laser Cutting Copper Successfully?

The challenges associated with laser cutting copper all pretty much boil down to its inability to absorb enough laser energy. That said, if you carefully optimize your laser power settings, you can work around it.

- Laser power: For smooth and efficient cutting on copper, set the machine to maximum power throughout the whole process. This will reduce the amount of time the copper is most reflective. The table below provides a rough guide to the most suitable laser power for a range of copper thicknesses:

| Material Thickness | Power |

|---|---|

Material Thickness 0.04-0.06” (1–1.5 mm) | Power 1000W |

Material Thickness 0.08” (2 mm) | Power 1500W |

Material Thickness 0.12” (3 mm) | Power 2000W |

Material Thickness 0.16” (4 mm) | Power 3000W |

Material Thickness 0.25” (6 mm) | Power 4000W |

Copper Thicknesses for Laser Cutting

- Cut speed: Keep this at 85–90% of the maximum speed allowed. That will keep the copper heated and not highly reflective, which should allow you to keep cutting without any interruptions. If you do make some cuts that are unsuccessful at first, you can reduce the cutting speed a little.

- Point of focus: This can be adjusted using different optical lenses and changing the distance between the lens and the worktable. Keep the focal point on the surface of the workpiece, or as close as possible, to maximize the energy density of the laser at the surface of the workpiece. This will ultimately melt it faster.

- High-pressure oxygen gas: Although we’ve saved this for last, it’s actually a high-priority point because this is what will make that reflectivity-reducing copper oxide we mentioned. Aim for 100–300 psi, depending on the thickness of your material.

Does Oxygen Assist Gas in Making Copper Cut Faster?

Yes, oxygen gas makes copper laser cutting faster. While copper laser cutting can be accomplished without oxygen-assists gas if using a fiber laser, the presence of oxygen creates an exothermic reaction that helps make the laser cutting process more efficient. This is more applicable to CO2 laser cutting than fiber laser cutting. The exothermic reaction between the copper and the oxygen creates heat and copper oxide at the material surface. The copper oxide then reduces the workpiece's reflectivity, which assists in increasing the absorption of the laser energy. Using oxygen during cutting makes the process easier. However, it also leads to the formation of burrs along the length of the cut. This results in additional post-processing of the part to achieve the desired surface finish.

Does Employing Faster Cut Speeds Cut Copper Well?

No, using faster cutting speeds is not an effective way to laser-cut copper. Because of copper’s high reflectivity, faster cutting speeds prevent the laser from effectively heating the surface of the workpiece. This can cause reflection back into the optics and potential damage to the laser system. It is best to start with slower cutting speeds, coupled with a high-powered laser that is focused on the surface of the workpiece. This will maximize both the heat generation rate in the copper and the amount of energy absorbed.

FAQs on Copper Laser Cutting

Can you laser-cut copper with a low-powered laser?

You can, but a high-powered laser can better provide the energy needed to cut through copper, leading to better results. For a low-powered laser, you’ll need to keep the cutting speed low and carefully adjust settings like focus and pulse frequency.

Does Using a Fiber Laser Make Cutting Copper Easier?

Yes, but it’s harder to do than with a fiber laser because the copper will reflect the laser’s red and infrared wavelengths. But there is a workaround; you can coat the copper with a metal marking spray or paste, which will allow it to absorb the CO2 energy. It won't provide the same high-quality cut, or work as well as a fiber laser, but should be fine for small-scale or hobby projects.

Copper laser cutting vs. laser engraving–what's the difference?

Laser cutting is able to cut right through a material, whereas laser engraving just makes marks on the surface. The first can basically chop a workpiece into two or more pieces, while engraving is used to change the external appearance of the copper with logos, identification marks, designs, patterns, or other decorative details.

How is flame cutting different from fusion and sublimation cutting?

Fusion cutting uses an inert gas like nitrogen to force molten material from the slit or kerf, and sublimation cutting works by heating up the material so quickly that it doesn’t have much time to melt, so it’s directly vaporized. With this type of cutting, a shield gas is used to help prevent the edges of the workpiece from oxidizing. Flame cutting, as we’ve covered, uses oxygen.

How Xometry Can Help

Producing copper parts is more than possible at Xometry, and we have a long list of manufacturing services you can get quotes for depending on your needs, including copper CNC machining, copper sheet metal fabrication, and other related customized services. You can get an instant quote on these processes, as well as many others, easily on our website.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.