Disclaimer

Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network.

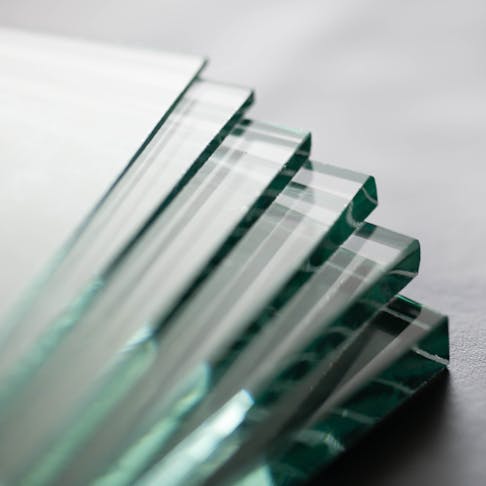

Laser cutting is used a great deal in manufacturing on materials like plastic, wood, and metal, but over the last few decades, it’s started gaining popularity for glass, too. Glass is notoriously brittle so using a laser on it may seem like a shattering waiting to happen, but with the right type of laser, it can be (and is) done with great success.

It might not be as common as the other materials, but laser cutting glass has become a go-to for many glass fabricators, manufacturers, and artists thanks to its accuracy, effectiveness, and adaptability. The lack of mass demand for it at the moment means that there are only a select few partners in our network that provide this service, which you can manually request a quote for via the Xometry Instant Quoting Engine®.

Let’s have a look at how this technique works, what types of glass can be cut, and, most importantly, how to do it.

What is Glass Laser Cutting?

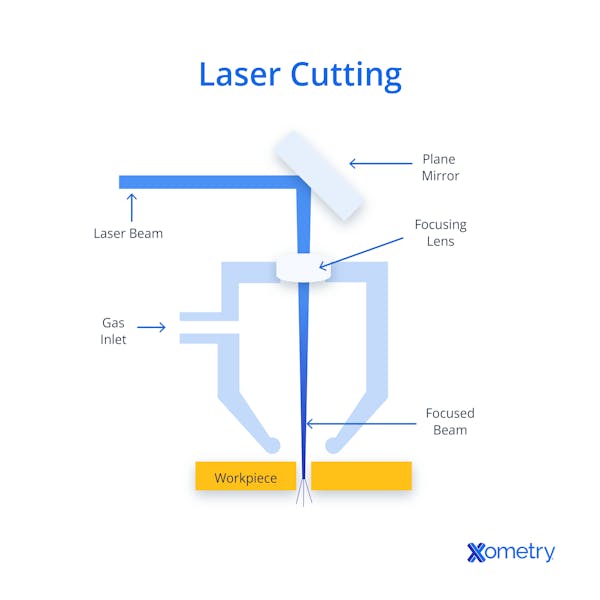

Glass laser cutting is the method of cutting glass materials using a high-powered laser beam. Unlike with other materials, glass laser cutting needs to be done with a specific kind of laser, namely ultrafast pulsed lasers (picosecond or femtosecond in the 10–100W range). These lasers emit a high-energy beam that focuses on the glass surface and, instead of literal “cutting,” provides clean, accurate fractures along a predetermined path. This is necessary because glass doesn’t melt in the same way as plastic to make a quick and clean cut.

The thermal stress induced by the laser then causes even thick or dense glass to cleanly separate, with minimal heat damage. This method can make intricate, highly detailed designs with reduced chances of chipping or cracking as the laser doesn’t actually come in contact with the material.

Techniques

There are three methods of cutting glass with a laser, which are described in the below table.

| Method | Laser type | How it works | Applications | |

|---|---|---|---|---|

Method Laser cutting | Laser type Ultrafast pulsed lasers (UPL) | How it works Creates controlled fractures along a set path, the thermomechanical stress separates the glass | Applications Precision parts for automotive, aerospace, and medical devices, electronics, display panels | |

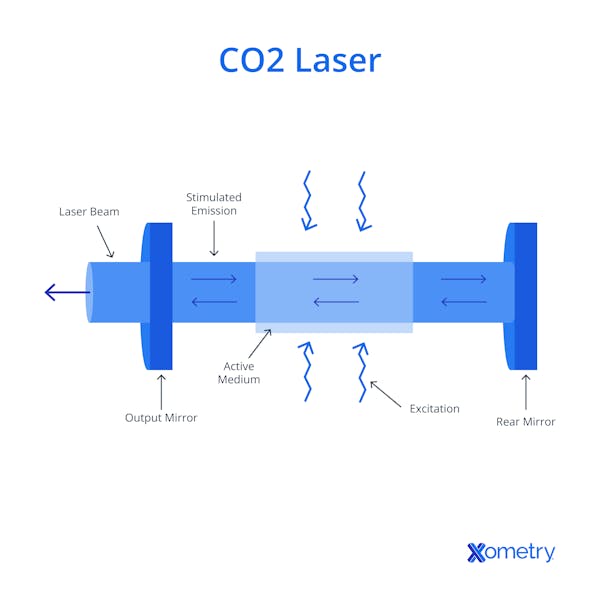

Method Laser engraving | Laser type Low-powered CO2 laser (doesn’t have to be as strong as with laser cutting) | How it works Carves out a permanent pattern/design into the glass surface by removing a small amount of material | Applications Personalized or decorative ornaments, glassware, signs, awards, and trophies | |

Method Laser etching | Laser type Various (CO2, UPL, UV) | How it works The laser exposure only alters the glass surface, producing a frosted effect | Applications Glass sculptures, decorative items, art |

Glass Laser Cutting Techniques

A Note on Glass

To understand how glass laser cutting works exactly, we need to first look at the type of material that glass is. We all know that it’s hard, brittle, and transparent, but it also boasts chemical resistance and electrical insulation, making it a staple in modern industry and technology. That’s not to say it’s a new material; glass dates back thousands of years when our ancestors discovered that they could make it by melting sand in a furnace. Today, the process of making glass isn’t too dissimilar to the early method; sand, soda ash, and limestone are mixed and melted together at a high temperature.

Glass blowing entered the scene sometime in the first century, and people started making glass items in various shapes, and in large quantities, and in the 19th century, the glass industry boomed. As a manufacturing material, it’s considered very versatile; it can be molded, painted, and coated depending on what it’s needed for. Some of its applications are things like windows, lenses, mirrors, containers, and even fibers, appliances, and screens on smartphones and tablets.

But back to glass laser cutting, there are many different types of glass, and not all of them can be put through this cutting method. For instance, stained glass is not ideal for laser cutting because its metallic oxides affect the laser absorption. Neither can tempered glass as it will totally shatter when the laser hits it due to internal stress.

The below table shows the glass types that are suitable for laser cutting:

| Glass type | Properties | How it’s made | Applications |

|---|---|---|---|

Glass type Borosilicate | Properties Superior chemical resistance, high heat resistance | How it’s made Silica, boron trioxide | Applications Laboratory equipment, kitchenware |

Glass type Aluminosilicate | Properties High strength and toughness, impact and scratch resistance | How it’s made Silicon oxide, aluminum oxide | Applications Smartphones, touchscreens |

Glass type Fused quartz | Properties High thermal stability, durability | How it’s made Silica dioxide | Applications High-temperature applications, lamps, furnace tubes |

Glass type Fused silica | Properties High purity and homogeneity | How it’s made Silica-based, made by the high-temperature melting of silica powder, can also be made with chemical vapor deposition | Applications Precision optics, lenses, mirrors |

Types of Glass Suitable for Laser Cutting

How to Laser Cut Glass

There aren’t too many steps in the glass laser cutting process, but that’s not to say that some expertise in the method isn't needed. For proper and safe cutting with lasers, you’ll need specialized tools and be trained on how to use them. These are the steps to follow to laser cut glass:

- Choose a piece of glass to work on, and make sure it fits inside your laser cutter.

- Make a DXF file of your design (if it’s a 3D model, you’ll have to convert it) for your laser cutter to read.

- Wear your PPE, such as safety goggles, mask, and gloves.

- When you’ve put the glass on the laser platform, turn on the ventilation system (usually a fan inside the machine).

- Load the DXF file into the laser cutter and set your cutting parameters—high power, low speed, and longer focal length (i.e., 150–200 mm) for clean cuts.

- Make a start! Keep an eye on the machine while it’s running to make sure everything is going smoothly and as planned.

- After the machine is done, you’ll likely have to sand down any sharp edges on the glass for obvious safety reasons. This can also be done by flame polishing.

FAQs on Glass Laser Cutting

What other methods are there for cutting glass?

Another common way to cut glass is with diamond-tipped cutters. These score the glass and create a dividing line, which the glass is then carefully snapped along. As you can imagine, this particular method needs a lot of skill, care, and precision. That’s why laser-cutting glass has largely taken over the space; it’s precise, can make detailed shapes and designs, and doesn’t have as much of a risk of chipping or cracking the glass.

What’s the best laser wavelength for glass cutting?

The most suitable wavelength for laser cutting glass with a UPL is around 1030–1064 nm (Nd:YAG, fiber, or diode-pumped lasers). UV wavelengths (355 nm) can also be used for more high-precision work.

Why are UPL pulsed lasers used instead of CO2 for glass cutting?

Glass absorbs CO2 laser energy and results in uncontrollable micro-fractures, which prevents the cutting of intricate shapes. High-power ultrafast pulsed lasers are the industry standard for precise glass cutting without excessive heat damage. The rapid duty cycle of these types of lasers reduces heat zones in the glass, and therefore reduces unwanted micro-scale cracking. UPLs are commonly used for this process, allowing for precise cuts with minimal cracking, whereas CO2 lasers are mainly only used for laser-engraving or etching applications. Similarly, continuous-wave lasers emit a steady beam which is suitable for engraving or etching but not cutting.

How Xometry Can Help

As mentioned early on in this article, we do have some glass laser cutting providers in the Xometry network, and you can request a quote from them directly from our website. You can also get an estimate on other related services, including CNC cutting and acrylic laser cutting, or reach out to one of our representatives with any questions.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.