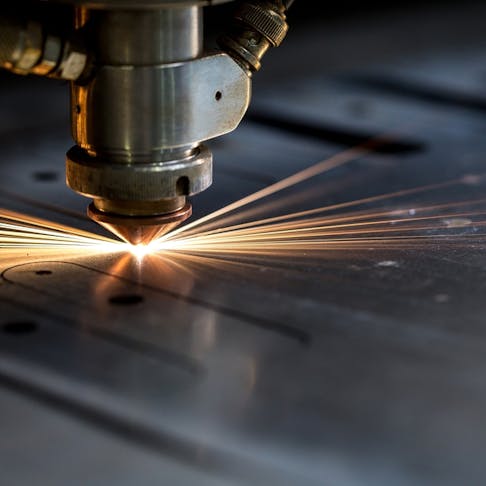

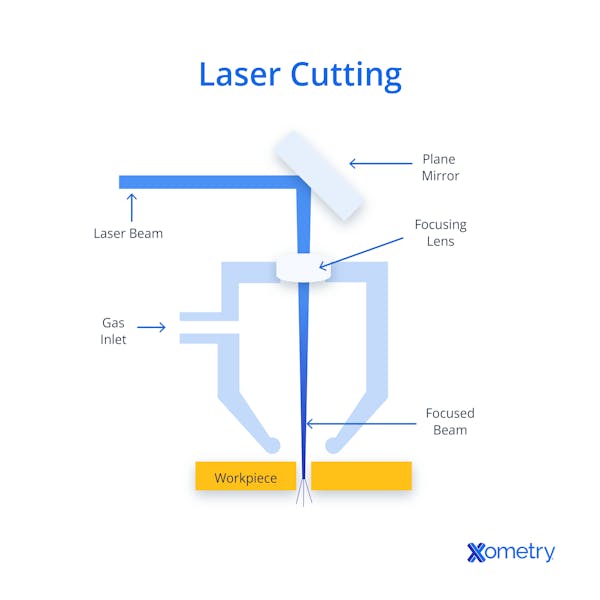

Laser cutting is a popular technology used in a range of different industries. It is used to cheaply and quickly produce flat, precisely cut components. The most common laser cutters are based on CO2 or fiber lasers. However, newer technologies, such as direct diode laser cutting, are gaining popularity. Industrial laser cutters are often used to cut metals, plastics, and even ceramics. Figure 1 below is a diagram of a laser cutting machine:

This article will describe how ten major industries make use of laser cutters, as well as review the characteristics of the major types of laser cutters and the main cutting techniques.

What Industries Use Laser Cutting?

Industrial laser cutters are used in most modern industries because they offer a low-cost, high-speed method for making high-precision cuts. Listed below are some common industries that use laser cutters:

1. Agricultural Industry

The agricultural industry is responsible for the large-scale cultivation of livestock and crops. The scale of modern agriculture demands heavy machinery and equipment to produce large volumes of food efficiently. This includes planting machines, fertilizing machines, and bulk storage tanks. Many types of agricultural machinery are primarily made of flat components with complex profiles that are joined by welding or fasteners. Laser cutting is ideally suited for economically producing the flat complex parts and weldments used extensively in this equipment. Tube laser cutting, a method of cutting holes and slots into a square or round tubing, is also extensively used for structural elements in agricultural equipment.

2. Contract Manufacturing Industry

Contract manufacturing involves outsourcing the production of subcomponents or complete assemblies to another company. Laser cutting is well-suited for this industry because, although the individual parts are inexpensive to produce, the high initial capital investment and ongoing maintenance costs of an industrial laser cutter require it to be in continuous use to remain profitable. Most companies do not have the capacity to justify an in-house industrial laser cutter, making contract manufacturing an ideal solution.

3. Military Industry

The military industry utilizes advanced electronics and heavy-duty machinery. These machines must be produced to exacting specifications using modern, difficult-to-process materials like hardened steel, non-ferrous metals like titanium, fabrics like kevlar, and advanced super alloys like Inconel®. Laser cutting is an indispensable process for fabricating the tens of thousands of parts and products made every year to meet military quality standards. Specific applications can include armored plates, permanent marking of equipment, and components for weapons systems.

4. Construction Industry

The construction industry builds large-scale projects such as bridges and tunnels, as well as residential and commercial buildings. Many structural steel components are fabricated using laser cutting. For example, connection plates and base plates are most optimally manufactured by using laser cutting. There are often thousands of these components for a major steel construction project, so laser cutting speed and precision give it a big advantage in these applications. Additionally, tube laser cutting is widely employed to fabricate structural elements.

5. Automotive Manufacturing Industry

The global automotive industry is a large consumer of manufacturing output, with over 90 million vehicles produced globally in 2024. The automotive industry demands highly precise parts with minimal variation, produced at high speeds to match the fast pace of vehicle manufacturing. Laser cutting is an ideal technology for meeting the simultaneous requirements of pace, precision, and repeatability. Typical examples of laser-cut components include sheet metal body elements and textiles for upholstery.

6. Musical Instruments Industry

Musical instruments must be manufactured with special precision to achieve the high level of sound quality demanded by professionals. Laser cutting is an ideal method for achieving unmatched levels of dimensional accuracy. Wood is a common material used in musical instruments, and laser cutters can precisely cut out the basic panels that will be assembled into instruments like guitars and violins, for example. The finished instruments can also be laser engraved with custom artistic patterns, adding cosmetic appeal and a personal style element.

7. Medical Equipment Industry

Medical diagnostic equipment such as X-ray and FMRI machines are complex pieces of equipment that employ several different manufacturing technologies. Laser cutting can be used to produce a number of components for these machines, such as their sheet metal housings.

8. Electronics Industry

Laser cutting is widely used in the electronics industry due to the precision required to process micro-scale electronics components. Silicon wafers are also cut using specialized laser cutting techniques such as fracture-controlled cutting, where a focused laser beam creates controlled micro-cracks along predetermined scribe lines, allowing for clean separation without excessive thermal damage. Other applications include laser engraving information onto components and drilling precise holes in printed circuit boards.

9. Furniture Industry

The furniture industry makes use of a range of materials such as textiles, wood, and plastics. Laser cutting can process these materials cost-effectively, which is why it is a popular technology in this industry. Textile and padding patterns can be cut for upholstery, and wood can be engraved with various designs. MDF (Medium Density Fiberboard) wood panels can also be cut to produce innovative furniture designs.

10. Arts

Laser cutters are regularly utilized for artistic purposes because they can reproduce intricate images on a wide variety of materials, such as wood, leather, metal, and plastic. Typical applications can include engraved inlays and complex art pieces built up from multiple-cut designs.

What Is Laser Cutting?

Laser cutting is a process that can make accurate, complex cuts completely through the thickness of such materials as metal, plastic, and wood. It does this by focusing a beam of light energy into a small point on the surface of the material to be cut, melting/vaporizing it, and blowing it from the cut path with the assistance of a gas jet. Metal cutting requires higher laser power than cutting plastics and wood. The most common industrial lasers employ fiber and CO2 lasers, although there are a number of laser-cutting technologies. For more information, see our guide on Laser Cutting.

What Are the Types of Laser Cutting Used in Industry?

Four general types of laser cutters are used in industrial applications, as listed below:

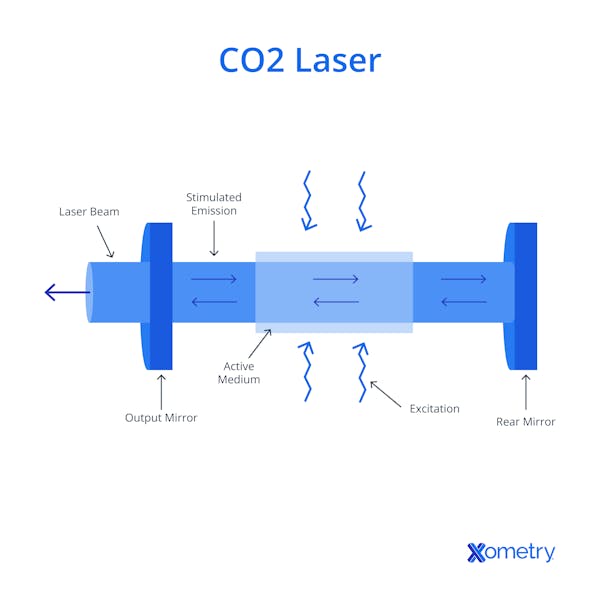

- CO2 Laser: CO2 lasers are based on technology developed several decades ago and are primarily used for cutting non-metal materials. While they can cut metal under specific conditions with assist gases, fiber lasers, developed more recently, are generally preferred for metal cutting in the automotive and manufacturing industries. The CO2 lasers also do well with organic materials like wood and fabric. They require regular maintenance, as their laser tubes tend to fail over time.

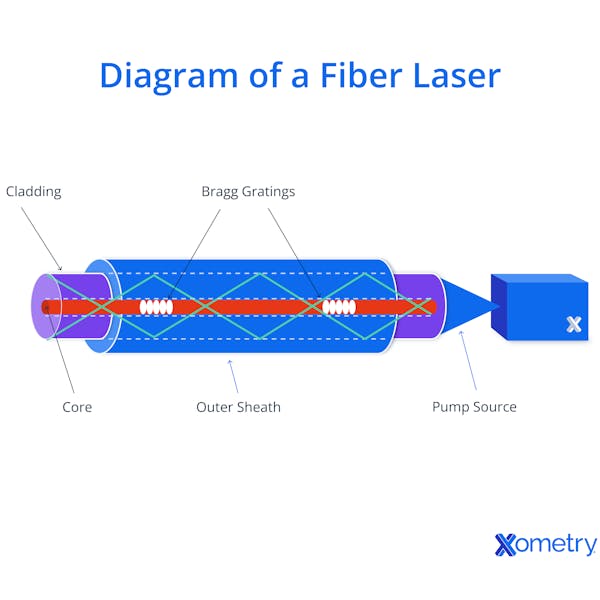

- Fiber Lasers: Fiber lasers are well suited for metal cutting and can produce precise cuts in a variety of materials. Fiber lasers have higher energy densities than CO2 lasers and are preferred over CO2 lasers in the automotive, manufacturing, and aerospace industries.

- Nd:YAG & Nd:YVO Lasers: These crystal-based lasers (Nd:YAG - Neodymium-Doped Yttrium Aluminium Garnet and Nd:YVO - Neodymium-Doped Yttrium Orthovanadate) have higher power densities than fiber lasers and are widely used for marking and etching as well as for use in the medical industry for various eye treatments. These lasers, however, have high operating costs and low efficiencies.

- Direct Diode Lasers: Direct diode lasers are far simpler than the other technologies in this list, and recent advances have achieved power densities high enough for cutting metals. Direct diode lasers can achieve high cutting speeds in certain applications, though the speed advantage over fiber lasers may vary depending on the material and specific cutting requirements. Due to the high precision, superior cut edge, and improved efficiencies, direct diode lasers are used for cutting superalloys like Inconel® and Hastelloy®, which are typically used in the aerospace and energy industries.

For more information, see our guide on Types of Laser Cutters.

What Are the Things You Can Do With Laser Cutting?

Apart from simply cutting materials, lasers can be used for a range of other techniques, as listed below:

- Perforating: Laser perforation is a process whereby a small hole, roughly the diameter of the beam, is made through the material. These holes are often very close to each other. An example of perforation would be the creation of tear lines in vehicle interior trim components so that they separate as intended when an airbag is deployed.

- Seaming: Seaming is a type of welding used to bond two thin materials to each other. It is often used on fabrics, as well as for welding thin metal components like those found in battery housings.

- Etching: Laser etching melts a thin surface layer of material in a prescribed pattern. It removes no more than 0.0001 inches of material and leaves a high-contrast image. Etching is often used to permanently mark components for traceability.

- Engraving: Laser engraving ablates surface material away to produce a 3D design. Two common techniques include concave and convex engraving.

- Marking: Laser marking is used to discolor the surface of a material by using a low-power laser beam. Unlike laser etching, laser marking does not remove any material from the surface. For some metals, the surface is annealed, which causes a color change.

- Drilling: Laser drilling is an alternative to mechanical drilling using a rotating drill bit. It is often used to cut very small, high aspect ratio holes of as small as 0.002” (~50 microns). These holes can be made to be extremely precise.

Common FAQs About Laser Cutting

How Does Laser Cutting Work?

Laser cutting works by directing a high-powered beam of light into a sheet of material to produce a 2-dimensional profile. In the case of common lasers like CO2 and fiber lasers, the beam is generated inside a resonator that amplifies the light energy until it reaches the desired energy level. The beam is then directed using mirrors (in CO2 lasers) or fiber optic cables (in fiber lasers) onto the material surface. The laser melts, burns, or removes the material to create the cut-through.

Is There an Industry That Offers Laser Cutting Services?

Yes, the contract manufacturing industry offers various laser-cutting services. Outsourcing laser cutting is an excellent way to save money, as the initial capital investment for a laser cutter is significant.

Summary

This article reviews how laser cutting is applied across industries - from agriculture to electronics - detailing its process and key technologies such as CO2, fiber, Nd:YAG/Nd:YVO, and direct diode lasers, along with various techniques like engraving and drilling. To learn more about laser cutting and our manufacturing services, contact an Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including laser cutting, sheet metal fabrication, CNC machining, 3D printing, and injection molding. Visit our website to learn more or to request afree, no-obligation quote.

Copyright and Trademark Notices

- Inconel® is a registered trademark of Special Metals Corporation

- Hastelloy® is the registered trademark name of Haynes International, Inc.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.