Laser cutting is a general term for the use of a beam of coherent photons to deliver highly concentrated energy in a narrowly focused hot spot. The beam causes melting, vaporization, and ablation of a wide variety of materials. Laser sources used are such as those driven by CO2, metal-doped silica glass NdYAG, and doped liquid crystal devices at the low end of the power range.

Applications of laser cutting are diverse and increasing in range. They include: the manufacturing of sheet components, high-speed cutting of tubes, engraving of fine patterns, micro drilling through diamonds, and micro welding in chip manufacture.

Laser cutting offers advantages over more traditional processing methods, including: high precision, no material contamination, high speed, and unlimited 2D complexity. Its disadvantages, on the other hand, include: limitation of material thickness, harmful gases and fumes, high energy consumption, and high upfront costs. Despite the extreme capabilities that laser cutting offers, some alternatives offer similar performance from quite different methods including: waterjet cutting, CNC machining, and plasma cutting. This article will further discuss the laser cutting advantages and disadvantages, explain the laser cutting process, and provide alternatives to laser cutting.

What Is the Laser Cutting Process?

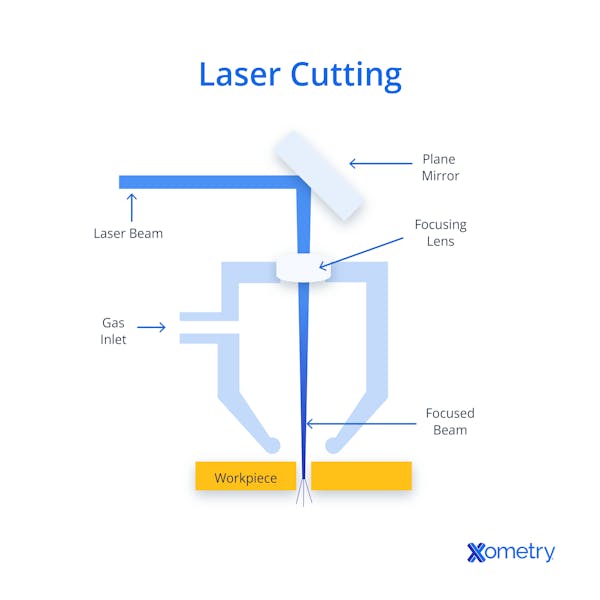

The laser cutting process uses a tightly focused high-energy light/radiation laser beam to create rapid, high-temperature-gradient heating of a single, small-diameter spot. This triggers rapid melting/vaporization of the target material, allowing the spot to travel down through the material thickness rapidly and precisely.

The hot spot is blasted with gas, blowing away the melted/vaporized material. This process exposes the cut bottom to allow renewed melting and localized cooling, enabling the cut to proceed. For lighter and more reactive metals, the gas assist uses nitrogen to minimize oxidation. Alternatively, for steel, oxygen assistance accelerates the cut process by locally oxidizing material to assist in slag clearance and reduce the reattachment of melted/cut material.

Laser cutting machines are built in a variety of formats. The most common type keeps the workpiece stationary while laser optics (mirrors) move in both the X and Y axes. Alternatively, a “fixed optic” format keeps the laser head stationary and the workpiece moves. A third option is a hybrid of the two previous methods. All methods execute 2D and 2.5D G-code patterns using a computer-controlled programming system to deliver fully automated, complex cutting paths. Figure 1 is an example of a laser cutting process:

Laser Cutting Advantages

Laser cutting advantages include: high precision, no material contamination, high speed, unlimited 2D complexity, a wide variety of materials, and a wide variety of applications and industries.

High Precision

The narrowness of the energy beam and the precision with which the material and/or the laser optics can be moved ensures extremely high cutting quality. Laser cutting allows the execution of intricate designs that can be cut at high feed rates, even in difficult or fragile material substrates.

No Material Contamination

Traditional rotary cutter processing of materials requires coolants to be applied. The coolant can contaminate the cut parts, which must then be de-greased. Grinding processes may also require coolant/lubricant to be applied. The ablation of the grinding wheel, a natural part of the process, leaves carbide granules that are a hazard in many products. Similarly, water cutting leaves garnet residues. Laser cutting involves only energy and gases and poses no risk of material contamination of the resulting parts.

High Speed

Few production methods can come close in processing speed to laser cutting. The ability to cut a 40 mm steel sheet using a 12 kW oxygen-assisted laser provides speeds some 10x faster than a bandsaw and 50–100 times faster than wire cutting.

Unlimited 2D Complexity

Laser cutting allows intricacy through the nature of the G-code movement control method of positioning and the small size of the applied energy hot spot. Features that are only weakly attached to the main body are cut without any application of force, so the process is essentially limited by material properties, rather than process capabilities.

Variety of Materials

Laser cutting is a flexible technology that can be adapted to cut widely different materials efficiently, including: acrylic and other polymers, stainless steel, mild steel, titanium, hastelloy, and tungsten. This versatility is increasing as technology develops. For example, dual frequency lasers can be applied to cut carbon fiber reinforced composites—one frequency for the fiber, one for the bonding agent.

Variety of Applications and Industries

Laser cutting finds application in many manufacturing industries because of the combination of versatility, high processing speeds, and precision. Sheet materials are key to production across most manufacturing industries. Applications of laser cutting across industries include: airframes, ships, medical implants, electronics, prototyping, and mass production.

Laser Cutting Disadvantages

Laser cutting disadvantages include: limitations on material thickness, harmful gases and fumes, high energy consumption, and upfront costs.

Limitation on Material Thickness

Most laser cutting machines sit in the <6 kW range. Their cut depth is limited to ~12 mm in metal thickness—and they accomplish that only slowly (~10 mm/s). It requires the largest and most powerful machines to reach the practical limits of cutting. However, similar limits apply to waterjet and wire erosion cutting. All three processes perform these deeper cuts faster than can otherwise be achieved.

Harmful Gases and Fumes

While many materials—particularly metals—do not produce harmful gases in the cutting process, many polymers and some metals do. For example, PTFE and various fluoropolymers produce phosgene gas (which is incompatible with human environments) when heated to high temperatures. These materials require controlled atmosphere processing.

High Energy Consumption

Laser cutting machines have a higher energy consumption rate than other cutting tools. A 3-axis CNC machine cutting out 40 mm steel plate blanks will consume around 1/10th of the power of a laser cutting machine extracting the same part. However, if the processing time is 1 minute on the laser cutter and 20 minutes on the CNC, the net power usage is 2:1 in favor of the laser cutter. Each part will have a different profile in this regard, but the differentials are rarely simple to analyze.

Upfront Costs

Headline costs for laser cutting machines vary widely. Examples of upfront costs are:

- Typical 1–3 kW entry-level machine-shop devices start at around $2,000 for machines suited to relatively light use with up to 10 mm steel sheet and moderate throughput.

- Higher-power machines in the 6–10 kW range, capable of greater cut depth and faster processing, start at $10,000 and range up to $150,000 for popular brands and high-capacity machines.

- This compares well with an entry-level 3-axis CNC machining center at $8,000 or a similar grade 5-axis CNC at $24,000, rising to $260,000 for sought-after brands and exceptional performance.

If running your laser cutting shop, the upfront costs of laser cutter equipment and training can be significant. However, the cost of using a laser cutting service like Xometry is very reasonable.

Alternatives to Laser Cutting

The alternatives to laser cutting are wire cutting, plasma cutting, waterjet cutting, and CNC machining.

Plasma Cutting

Plasma cutting is similar to electrical discharge machining (EDM) in that it erodes material by applying an arc to ablate the substrate. However, the arc is conducted from an electrode on a superheated gas plasma stream that directs the arc and blasts out the molten material from the cut. Plasma cutting and laser cutting are similar in that both are capable of cutting metal parts. Additionally, plasma cutting is suited to heavy materials and relatively coarse processing, for example, preparing heavy steel components for architectural and ship projects. It is a much less clean process and generally requires significant post-cut cleanup to make presentable parts, unlike laser cutting.

Waterjet Cutting

Waterjet cutting is typically a small machine process for the precise processing of a wide range of materials. The garnet abrasive employed is considerably harder than the majority of processed materials, but the hardest workpieces do pose a challenge for the process. Waterjet cannot match the processing speeds of laser cutting on thicker, hard substrates. In terms of similarities, both waterjet cutting and laser cutting produce high-quality cut parts, are suitable for working with many materials, and both processes have a small kerf (cut) width.

CNC Machining

CNC machining is considered one of the more traditional methods of extracting parts from flat material stock. It is similar to laser cutting in that both produce high-precision parts, are fast, reliable, and provide excellent repeatability. Compared to laser cutting, CNC requires more setup and more processing time. CNC also delivers lower throughput/capacity and requires greater manual intervention. However, results can be of similar quality, albeit at a generally higher cost. Rotating cutting tools apply considerable forces to the cut material and can result in more extensive local heating. The main advantages of CNC processing are the ability to accommodate complex 3D designs and to perform partial depth (rather than through) cuts.

How Xometry Can Help

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free CNC machining quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.