Ever since lasers burst onto the manufacturing scene in the ‘60s, they’ve come in handy for everything from cutting and welding to 3D printing. They’re also widely used in engraving and etching machines by hobbyists and major manufacturers alike. Both laser etching and engraving can make intricate patterns and jazz up or personalize things like pens, jewelry, and nameplates, and it can be a common go-to for brand logos and motifs. But their usefulness isn’t limited to aesthetics. These methods are used for marking permanent traceable part identifiers, like serial numbers, QR codes, and barcodes, in very high resolution (even on the smallest of parts).

Part identification is actually a government safety regulation to help figure out the causes of failures or accidents. Parts that need to be labeled include drive shafts, engine blocks, and brake discs, to name just a few in the automotive sector, and in aerospace, it could be electrical circuit boards, landing systems, turbine blades, and hardware like bolts. Interestingly, in the medical industry, tools and other important items like forceps, scalpels, catheter connections, tubes, and implants are also marked so that they can be clearly identifiable.

Just a quick clarification before we go into the differences between laser engraving and laser etching: these are not forms of laser marking. Marking labels the parts with a low-powered laser and doesn’t change the part’s material. In both engraving and etching, the material’s surface is permanently marked—in that it’s deformed—and can’t be scratched off. Now that’s out of the way, let’s get to it. In this article, you’ll learn about these two laser techniques, how they work, and how they’re different from one another.

What is Laser Engraving?

The laser in a laser engraving machine makes shallow cuts by vaporization. In this method, excess material is removed to make the complex patterns and designs required. The process needs a very high laser power to reach the required temperature for vaporization.

What is Laser Etching?

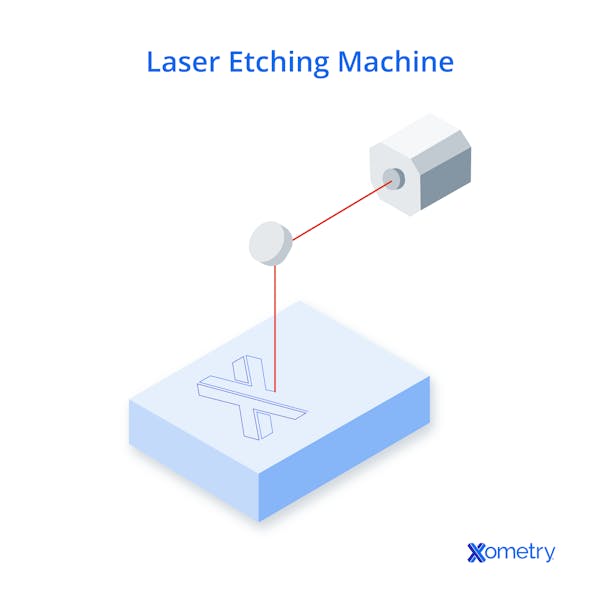

Similarly, laser etching also removes material to make the markings, but instead of vaporizing it, the workpiece is melted where necessary. The laser causes the material to expand at the point of focus, and this leaves a raised mark that can be seen and felt with your fingers. It doesn’t go as deep as to cut the workpiece, but just enough to mark it. Below is a diagram of how this process works.

In addition, laser etching has fewer power requirements and less energy density than laser engraving (melting is a lot more cost-effective than vaporizing, in both high and low production volumes), and is also a lot quicker. Here’s a picture of laser-engraved parts made by the Xometry team.

What Is the Most Commonly Used Technique Between Laser Engraving and Etching in Terms of Traceability of Parts?

Laser engraving and laser etching are both used to mark codes for traceability onto parts and components. The choices of engraving or etching depend on the part application. Laser etching is used for part identification more often than laser engraving for the two reasons described below:

- It is more cost-effective and uses less energy than laser engraving to produce patterns and codes.

- It is a faster process than laser engraving because the laser does not cut deeply into the workpiece.

What Is the Difference in the Process Between Laser Engraving and Etching?

In the below table, you’ll find the vaporization and melting temperatures of some common metals used with laser engraving and etching. As you’ll see, vaporization temperatures are much higher than melting temperatures—sometimes twice as high. The table only covers metals but both processes can also be used on wood and leather (as briefly mentioned above), as well as different types of plastic.

| Material | Laser engraving (vaporization temperature) | Laser etching (melting temperature) |

|---|---|---|

Material Cast iron | Laser engraving (vaporization temperature) ~5,072°F | Laser etching (melting temperature) ~2,372°F |

Material Aluminum | Laser engraving (vaporization temperature) ~4,352°F | Laser etching (melting temperature) ~1,220°F |

Material Carbon steel | Laser engraving (vaporization temperature) ~4,892°F | Laser etching (melting temperature) ~2,552–2,732°F |

Material Stainless steel | Laser engraving (vaporization temperature) ~4,892–5,432°F | Laser etching (melting temperature) ~2,732°F |

Material Titanium | Laser engraving (vaporization temperature) ~5,972°F | Laser etching (melting temperature) ~3,038°F |

Comparison of Vaporization and Melting Temperatures of Common Metals

| Factor | Laser Engraving | Laser Etching |

|---|---|---|

Factor Process | Laser Engraving Vaporization | Laser Etching Melting |

Factor Cut depth | Laser Engraving Up to 0.020 inch (varies with laser system’s power rating) | Laser Etching About 0.0001 inch |

Factor Cost (production, volume) | Laser Engraving More expensive | Laser Etching More cost-effective |

Factor Versatility | Laser Engraving Many different materials, but higher power requirements and slower process | Laser Etching Broader range of materials, quick production, low energy usage |

Factor Output durability | Laser Engraving Long-lasting and wear-resistant markings as these are cut deeper | Laser Etching Lower, markings are only produced at surface level |

Factor Power requirement | Laser Engraving Higher | Laser Etching Lower |

Laser Engraving vs. Etching

It’s worth noting that the cut depth can vary depending on the laser system’s power rating, energy density, and the material properties (i.e., its reflectivity). Wood, leather, and other organic materials are easier to etch or engrave because they’re not reflective so can readily absorb the lasers’ energy. Metals and other inorganic materials that tend to be reflective could make these processes a little more challenging.

1. Cut Depth

Cut depth is a critical aspect of the legibility of a marking and the marking’s wear and abrasion resistance. Marks produced by laser engraving have a depth of up to 0.020 inches. This can vary depending on the power rating of the laser system, energy density, and properties of the workpiece material such as reflectivity. Organic materials, like wood and leather, are easier to engrave and etch because they readily absorb energy from lasers and are not highly reflective. Whereas inorganic materials like metals have varying levels of reflectivity that make laser engraving and etching more challenging.

Markings produced by laser etching have little to no depth (about 0.0001”) since cutting isn’t actually performed. Instead, laser etching marks are raised above the surface of the part.

2. Production Volume and Cost

Laser etching is generally more cost-effective for both high and low production volumes. This is because etching requires less power to mark parts and is a faster process.

3. Applications

Laser engraving and laser etching are used in many of the same applications by hobbyists and commercial manufacturers. Both are used to mark parts for traceability purposes and create decorative patterns. Applications of both processes include engraving or etching products to add a personal touch such as pens, nameplates, belts, and jewelry.

In industrial applications, both are used in the automotive, aerospace, and medical industries. In these industries, manufacturers use laser processes to mark parts for traceability purposes with barcodes, QR codes, and serial numbers. Manufacturers also use these laser marking methods to mark parts with their logo or brand.

What Are the Differences in Versatility Between Laser Engraving and Etching?

Both laser engraving and laser etching can be used on various materials. However, laser etching is more versatile because it produces marks by melting. Laser etching can be used on a broader range of materials and rapidly produce marks while using less energy compared to laser engraving. Laser engraving can also produce marks, but its higher power requirements and slower process make it inefficient in many scenarios.

What Are the Differences in Output Durability Between Laser Engraving and Etching?

Markings made by laser engraving are more durable than those formed by laser etching. Laser engraving produces more long-lasting markings because the markings are cut deeper compared to the etching process. In laser etchings, markings are only produced at the surface of the part. Deeper cuts lead to more contrast between the marking and the rest of the part. The greater depth of the marking makes it more resistant to wear, enhancing its useful life.

Which Industries Make Use of Laser Engraving and Etching?

Industries that make extensive use of laser engraving and laser etching include the automotive, aerospace, and medical industries. Government regulations require components to be marked for traceability since many of the parts fabricated for use in these industries are safety-critical. These markings assist in determining the causes of failures or accidents involving the marked parts. Laser etching and engraving are especially valuable for creating permanent part identification because they can create high-resolution markings even on small parts. Examples of parts that receive identification markings include:

- Automotive: Drive shafts, steering columns, engine blocks, brake discs, and transmission cases.

- Aerospace: Electrical circuit boards, landing systems, turbine blades, bolts, and gear parts.

- Medical: Forceps, scalpels, catheter connections, medical tubes, implantable devices, and electrical circuit components.

What Is Cheaper to Use - Laser Engraving or Etching?

Laser etching is a cheaper process than laser engraving because it consumes less power and marks parts faster than laser engraving.

What Are the Best Machines for Laser Engraving?

| Laser Engraving Machine | Attributes |

|---|---|

Laser Engraving Machine Trotec SP Series | Attributes CO2 laser

Worktable: Up to 87” x 126.4”

Power: 60-400 W

Price: Start at $18,000

Best for industrial purposes |

Laser Engraving Machine Boss Laser™ LS Series | Attributes CO2 laser

Worktable: Up to 36” x 55”

Power: 50-155 W

Price: ~ $5000-$11,000

Best for industrial and small business applications |

Laser Engraving Machine Tool D1 Laser Engraver | Attributes Diode laser

Worktable: 17” x 16”

Power: 60 W

Price: $700

Best for small business and hobbyist applications |

Best Machines for Laser Engraving

| Laser Etching Machine | Attributes |

|---|---|

Laser Etching Machine FSL Muse® Core 40 W | Attributes CO2 laser

Worktable: 20” x 12”

Power: 40 W

Price: $3800 |

Laser Etching Machine OMTech CO2 Laser Engraver | Attributes CO2 laser

Worktable: 7.9” x 11.8”

Power: 40 W

Price: $420 |

Laser Etching Machine FLUX Beamo® 30 W | Attributes CO2 laser

Worktable: 11.8” x 8.2”

Power: 30 W

Price: $2300 |

Best Machines for Laser Etching

Frequently Asked Questions About Laser Engraving and Laser Etching

Are There Machines That Have Laser Engraving and Etching Features?

Yes, any laser machine that can engrave can also perform laser etching. This is because laser engraving is carried out at higher power levels than laser etching. The settings on a machine capable of engraving can be set to lower power and tailored to perform etching.

Are Laser Engraving and Etching Safe to Use for Glass Marking?

Yes, laser engraving and laser etching are safe to use for glass marking. It is recommended to adjust laser settings such as power and speed accordingly to avoid damaging or deforming the glass.

Are Laser Engraving and Etching the Same as Laser Marking?

No, laser engraving and etching are not the same as laser marking. In laser engraving and laser etching, the surface of the part is fundamentally changed and deformed. Laser marking is a family of techniques used to mark the surfaces of parts with a low-power laser without deforming the part.

Are Laser Engraving and Etching Important?

Yes, laser engraving and laser etching are important because both processes provide manufacturers with the ability to trace their parts in the event of a defect or recall.

How Xometry Can Help

If you’re thinking about laser engraving or etching, but aren’t sure which to go for, reach out to a Xometry rep who will be glad to assist you. The choice largely depends on what type of part you’re making and what it will be used for. If the decision is mainly down to your budget, then laser etching is the more cost-effective route, and it uses much less energy than laser engraving, too. It’s also a much faster process because the laser doesn’t have to cut the material very deeply.

In addition to these two laser processes, we have a wide range of manufacturing services to offer for many prototyping and production needs. If you already have your designs at the ready, you can also get a quick and totally free quote by uploading them to the Xometry Instant Quoting Engine®.

Copyright and Trademark Notices

- Boss Laser™ is a registered trademark of BOSS LASER.

- Muse® is a registered trademark of FSL.

- Beamo® is a registered trademark of FLUX.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.