Laser cutters are amazing tools, but like all tools, they pose potential hazards to the user. While they lack fast-moving sharps, they do still have moving optics assemblies. The laser itself has the potential to harm the skin and the eyes. Vaporization and scorching/decomposition of the cut material can also release harmful gas, dust, and smoke.

It is essential that user safety is treated with seriousness. The most common and appropriate safety gear when using laser cutters is:

1. Fire Extinguisher

The most obvious risk in operating a laser cutting machine is an ignition of the target material. Lasers rely on generating very high temperatures in the target, to locally char or vaporize the cut zone. Most non-metals that can be cut are flammable. An operating assumption of the risk of fire is a basic precaution for users. A fire extinguisher is a must-have safety accessory. It must be kept close to the machine and maintained in functioning condition. It should be certified and within the recommended service date. Dry powder extinguishers are very effective and have a long operational shelf life. They do leave a mess to clean up, but it’s not hard to remove with a vacuum cleaner. The most common choice for home use is the CO2 extinguisher. They can be hard to use for larger fires. However, for small and contained equipment fires such as those in laser cutting, CO2 extinguishers are simple, effective, and damage-free. Figure 1 below is an example of a CO2 fire extinguisher:

CO2 fire extinguisher.

Image Credit: Shutterstock.com/Mr.Zach

2. Safety Glasses or Goggles

Laser light is highly concentrated energy. In normal operation, it is virtually impossible to put the eye directly into the beam path. Backscatter of low coherence but nonetheless harmful radiation can easily damage the retina. Appropriate filter-type safety goggles are widely available and low cost. Choose an option that is right for the frequency of the laser you are using. For example, goggles that are optimized for UV may be quite ineffective at blocking IR. Most machines will be supplied with goggles. The manufacturer will generally recommend replacements. Figure 2 below is an example of a safety goggle for lasers:

Safety goggles for laser cutting.

Image Credit: Shutterstock.com/Hennadii Filchakov

3. PPE

Personal Protective Equipment (PPE) for laser cutting includes items such as: coveralls, head covers, and face shields. The hazards in laser cutting are rarely “whole body”, but all machining processes tend to produce contaminants that are best excluded from direct contact with skin, clothing, and hair. For lightweight home equipment, PPE is possibly not required, but for higher-energy equipment performing heavier work, it is strongly recommended.

4. Gloves

While the risk to hands is low, it is non-zero. There are three main hand hazards that must be addressed: burns, cuts, and chemically hazardous material contact. Equipment fault or loss of concentration may result in burns, either from the laser light or from hot parts. The beam is invisible, only showing when impacting matter that obstructs it. It is recommended to wear leather work gloves which will give some warning of the beam's presence before skin damage occurs, specifically for low-power home equipment. With higher-power equipment, gloves will barely delay the onset of serious injury, so ensure that the machine is powered down and has a service tag on the power controls before accessing the beam path. Leather work gloves are also recommended for heavier or potentially hazardous materials. Disposable rubber gloves, on the other hand, are suggested for lightweight materials and for handling chemically hazardous materials. Figure 3 below is an example of a leather glove:

Leather glove for safety purposes.

Image Credit: Shutterstock.com/masa44

5. Masks

A wide choice of filter masks are available to protect against the effects of hazardous substances present as powders. A simple paper element filter will be effective at removing almost all dust particles, as long as the mask is close-fitting and face sealed. The mask must preferably have an outflow valve to prevent the act of exhaling from lifting the mask and potentially allowing contamination past the face seal. If volatile, smoke, or sub-micron particulate particles are present, then a filter mask that integrates both particulate and adsorptive elements (such as an activated carbon filter element) is a better choice. This will reduce the potential exposure of very vulnerable tissues to unknown and unmeasurable toxicity. Life-threatening consequences of such exposures can be long delayed, so an assumption of high risk is a logical position.

6. Hearing Protection

Some large laser cutting machines can produce irritant noise levels, although these are rarely harmful. Experience with a machine will allow a personal choice to be made about this safety-gear option—but an assumption of risk is advised.

What Problems Could Occur if Safety Gear & Tools Are Not Used When Laser Cutting?

Non-use of safety gear when using laser cutters can cause significant problems such as health issues and fire risks. Dust, volatiles, and combustion products present the most pernicious and potentially long-term harm to machinery users. Many materials can produce respiratory inflammation and irritation. Combustion products in particular can be carcinogenic and toxic. Additionally, laser cutters are among the class of machine that creates a greater fire hazard by cutting and combustion. It is recommended to follow all safety precautions stated by the OEM.

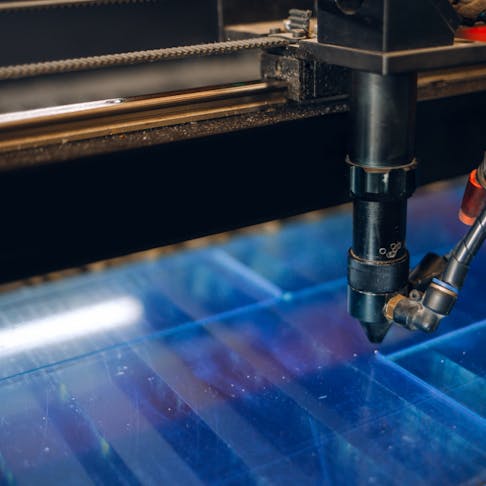

What Is Laser Cutting?

Laser cutting uses the ablation by melting or charring of material by laser light. It makes narrow cuts using a focused and coherent beam of typically UV radiation following a controlled path to “extract” parts from a sheet/block of material. The removed/destroyed material exits the cut either as char, vapor, or melted droplets, usually assisted by an air current. Additional cutting performance can be achieved by an aggressive nitrogen assist to clear debris, or an oxygen assist to oxidize melted materials (usually metals) to speed up the destruction of the cut pathway. Laser cutting is widely used in various industries including: automotive, medical, jewelry, metalworking, and woodworking. Laser cutters help produce car components, pacemakers, intricate jewelry, pipes, and types of furniture.

What Are the Dangers of Laser Cutting?

The dangers associated with laser cutting are essentially twofold: universal dangers in the use of machine tools and thermal-based cutting processes and laser-specific safety hazards. Some examples of dangers with machine tools and thermal-based processes are: smoke, vapor, and particles in the air, fire risks from hot cutting, moving-equipment hazards (impacting, pinching, or trapping a person), and electrical hazards from faulty wiring. Laser-specific safety hazards include extreme danger to the eyes due to the coherent light and highly concentrated radiation that can cut fast and deep into skin and tissue.

What Are Some Laser Cutting Safety Tips?

Some laser cutting safety tips are listed below:

- Never operate the laser cutting equipment unattended.

- Keep the table and the work area clean.

- Use all provided and recommended safety equipment.

- Use interlocked, laser-proof covers when available. Use a non-interlocked screen at least.

- Keep a fire extinguisher on hand and ensure it is within its use date.

- Precautionary “warning, laser light” signs are not required for home equipment, but are advisable in shared areas.

- Ensure good ventilation in the workspace and vent air extraction outside.

For more information, see our guide on Laser Cutting Safety Precautions.

What Are the Things To Avoid When Laser Cutting?

The things to avoid when laser cutting are listed below:

- Don’t assume the process is safe just because the hazards are not clear.

- Don’t bypass safety features like cover interlocks.

- Don’t vent cutting gases/smoke into the workspace.

- Don’t fail to act when a hazard is identified.

- Don’t operate messy equipment; clean up first.

- Don’t operate potentially faulty equipment; check and repair first.

- Don’t closely watch the cut point without good-quality eye protection.

Are There User-Friendly Laser Cutting Machines?

Yes, there are user-friendly laser cutting machines. Laser cutting machines range from very low-power desktop devices with no cover and no “user protection” features, through mid-range machines with good safety features, up to immense industrial machines that pose life-threatening risks and require very careful and experienced supervision.

Selecting a laser cutter is first a functional decision. The choice between prioritizing function or safety often comes down to budget. The lowest power and simplest machines are designed for home use, so they’re specifically designed for the less experienced user and they’re made to be easy to operate. The Laser Pecker 2 laser engraver is a low-cost, open-frame machine. But it’s easy to use and quick to set up. In the mid-range, machines have more power and usually an enclosure that makes them safer. The Glowforge® and xTools M1 are good options that are widely appreciated as being easy to use.

Is Laser Cutting Harmful to the Human Body?

Yes, laser cutting is harmful to the human body. The use of safety gear when using laser cutters is essential. The risks to the operator and others in the machine environment are significant but very manageable. Productive activities are virtually never without risk, so the key with laser cutters, as with any tools, is to stick to good practices and avoid hazardous behaviors.

Summary

This article presented safety gears and tools for laser cutting, explained what they are, and discussed the importance of each one. To learn more about laser cutting safety, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notices

- Glowforge® is a trademark of Glowforge Inc.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.