Gas welding, also known as oxy-acetylene welding (although nobody really calls it that), is a common fabrication process that can be done pretty much anywhere since you don’t need to be near an electrical outlet, and don’t need copious training, either. In this article, we’ll learn more about it, including when it’s used, its different types, and its pros and cons.

What is Gas Welding?

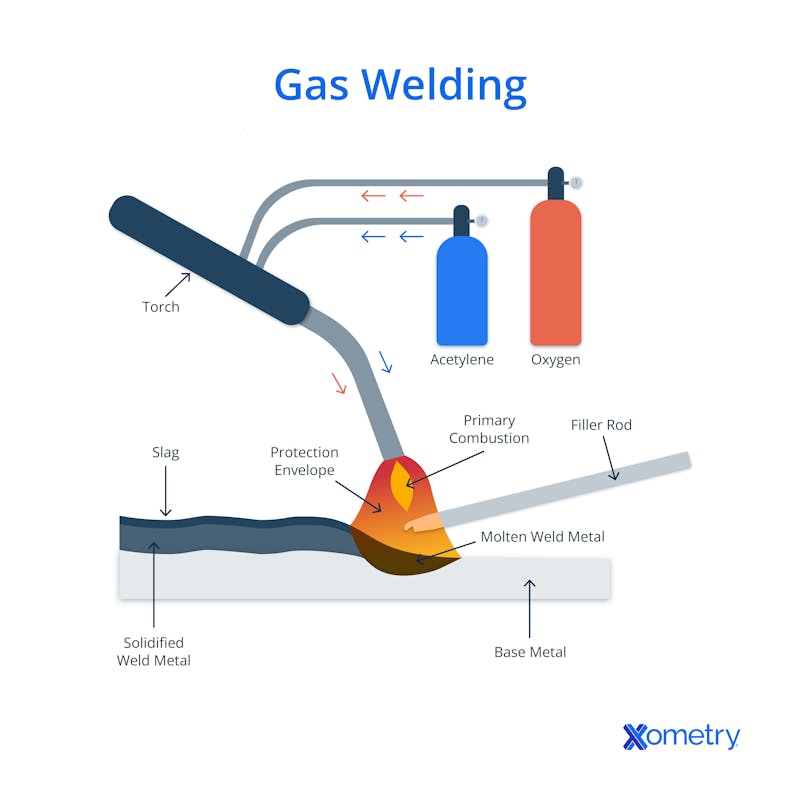

Gas welding uses oxygen and fuel gas to create a hot flame that can melt parts of metals and join them together. When cooled, this creates a very strong bond. To a certain extent, gas welding has been replaced by electrical welding forms (they’re cheaper and don’t involve gas which could be considered a safety hazard by some), but gas welders are still very much in use by hobbyists and professionals (including some Xometry customers) alike as it’s effective, simple, and portable. The below diagram explains how the process works:

There are five types of gas welding which are categorized according to what gas is used (not all gas welding methods use the same type of gas). These are butane or propane, hydrogen, MAPP (methylacetylene-propadiene propane), oxy-acetylene, and oxy-gasoline. You’d usually opt for different fuel gases depending on your circumstances and what you need to weld. Although it's often used for repair work, gas welding can be turned to for fabricating sheet metal, joining aircraft parts, making automotive chassis and frames, and even joining high-carbon steel. If parts need to look good, too, they’ll more than likely have to go through some form of post-processing.

What Is the Other Term for Gas Welding?

Gas welding is a general term that covers a few subcategories of welding. Acetylene welding is another term used interchangeably with gas welding because acetylene is the most common welding fuel. Specific types of gas welding include: oxy-acetylene, oxy-gasoline, MAPP, butane, propane, or hydrogen gas welding.

What Is the Importance of Gas Welding?

Gas welding is important in the fabrication of metal products. It’s a simple, mobile, and economical method for joining metal parts.

What Is the Purpose of Gas Welding?

The purpose of gas welding is to fuse ferrous or nonferrous metal items together and may be used instead of other fastening techniques. Manufacturers may choose gas welding over other forms of welding because it’s cheap and the equipment is portable.

How Does a Gas Welding Work?

Gas welding works by feeding both oxygen and fuel gas out of the end of a torch to produce a highly concentrated flame that can melt metal. Material is melted at the seam between two parts to create what is known as a weld pool. The pool then cools and bonds the pieces together to form a strong joint. The welder’s flame must be moved slowly to allow the joint to cool without oxidation which can create brittle connections.

What Are the Key Parameters of Gas Welding?

Your temperature, pressure, speed, and torch position can easily change depending on how you’re welding (i.e. the type of fuel you’re using, your oxygen ratio, or your ambient conditions). Let’s see how:

- Temperature: To control the temperature of a gas welding flame, all you have to do is adjust the ratio between oxygen and fuel. The more fuel you add, the lower the temperature will be. That way, you can adjust the temperature to match each material’s melting point. But, for high-strength steel, the heat could mess with its mechanical properties.

- Pressure: By adjusting the pressure ratio between the delivery of oxygen and the fuel gas, you can get three types of flames: neutral, oxidizing, and carburizing. The most common of these is the neutral flame, which is easy to spot because it has a small bright white inner flame and a larger blue flame around it. You can get it by mixing almost equal amounts of oxygen and fuel gas. For an oxidizing flame—perfect for welding cast iron and zinc alloys—mix more oxygen than fuel gas. You’ll notice that the inner flame is much shorter and more pointed and burns slightly hotter than a neutral flame. If you mix more fuel gas than oxygen, you’ll get a carburizing flame, which has a visible secondary flame between the short inner one and the larger outer one. This type of flame is popular among Xometry customers for welding aluminum and its alloys.

- Speed: The speed at which you need to weld depends on how long it takes to form a proper weld pool. Be careful not to move so fast that the weld doesn’t complete, and don’t move slow enough to burn a hole through the material. In general, this type of welding isn’t as hot as other types, so it might take a little longer.

- Torch Position (aka Gun Position): The torch position can directly affect the weld pool size. If you notice your weld pool getting too big, it means everything’s getting too hot, so try moving the torch parallel to the weld to reduce some of the heat. On the other hand, if the weld isn’t receiving enough heat and the weld pool is too small, move the torch almost perpendicular to the weld. Also, adding filler material needs heat, so it becomes easier and faster to do so when your weld pool is very hot. Another thing to be aware of is that this type of welding lacks flux shielding, so keep an eye out for any defects in the weld.

What Are the Different Types of Gas Welding?

There are five main types of gas welding. They differ by the fuel gas involved:

- Butane or propane welding

- Hydrogen gas welding

- MAPP gas welding

- Oxy-acetylene gas welding

- Oxy-gasoline gas welding

What Are the Applications or Uses of Gas Welding?

One of the primary uses of gas welding is repair work. This technique is better than most at bridging gaps between parts. Other applications of gas welding include:

- Fabrication of sheet metal

- Joining of aircraft parts

- Automotive chassis and frame fabrication

- Joining of high-carbon steel

How Does Gas Welding Being Utilized in Aerospace Industry?

Gas welding was the primary welding technique used in aerospace up until the mid-1950s when arc welding became widespread. However, gas welding is still used for the fabrication and repair of aircraft structures.

How To Use a Gas Welder?

Here’s your cut-out-and-keep, step-by-step guide on how to use a gas welder:

- Make sure you have all the equipment you need, that it’s all securely attached, and that the nozzle is clear.

- Put the metal on some heat-resistant material like fire bricks, and make sure it’s secure and won’t move around.

- Adjust the fuel gas with the nozzle’s regulator closed. Open the cylinder shut-off valve, and slowly open the regulator to the pressure you want. When that’s set, close the fuel gas shut-off valve at the torch.

- Do the same as step 2, but now with the oxygen supply.

- Only turn on the fuel gas at the torch and ignite the flame. At first, the flame will let off some black smoke from the unburnt carbon, so make sure you don’t breathe any of it in. Then, open the fuel valve at the torch until the smoke stops.

- Open the oxygen valve at the torch and adjust it until you get the type of flame you need

- Make a tack weld at each end of the joint to stop the pieces from moving during welding. You can do this by holding the torch at a 45-degree angle close to the metal and moving in a zigzag pattern between the metals. When they heat up and a weld pool forms, remove the heat.

- Welding the joint is very similar to making the tack welds. Move in the same zigzag way at the same angle across the two pieces of metal until the pool starts to form. Then, push the pool along by moving the torch slowly from one end to the other.

- When you’ve finished, let it air-cool. Don’t involve water because that’ll make the weld brittle.

- When shutting everything off, always turn off the fuel gas first and then the oxygen, and then close the shut-off valves at the cylinders.

What Are Tips and Strategies To Have a High-Quality Gas Welding Result?

Here are a few tips to improve your gas welding technique:

- Use a zigzag or circular motion to evenly heat both metal items.

- Hold the torch at a 45-degree angle to the weld, then tilt it as needed to increase or decrease the impinging heat.

- Hold the torch 2-3 mm away from the weld site.

- The bigger the weld pool, the better the weld penetration. Be careful not to let the weld pool get large enough to create a hole.

- Small explosions at the nozzle signify that either the torch is too hot, it’s not getting enough fuel gas, or the nozzle needs to be cleaned.

Is Gas Welding Hard?

No, gas welding is one of the easier forms of welding. Beginners are often required to master gas welding before moving on to electrical methods.

Is Gas Welding for Beginners?

Yes, gas welding is good for beginner welders, although metal inert gas (MIG) and tungsten inert gas (TIG) may be easier for beginners.

What Are the Materials That Can Be Used in Gas Welding?

Most metals can be gas welded to metals of the same type. For example, steel can be welded to steel, but not to aluminum. Another benefit of this process is that it’s compatible with both ferrous and non-ferrous metals.

1. Aluminum

With a relatively low melting point of 1,220 degrees Fahrenheit, aluminum is welded using a carburizing flame. When gas welding aluminum, it’s important to remove the oxide layer with a brush because it has a much higher melting point than the aluminum itself.

2. Copper

One of the most popular metals among our customers for making water and gas pipes, copper pipes can be connected either by gas welding or forming using compression joints. Copper is slightly different from other metals when welding, in that you need to place a fitting over the pipe first, and heat it along with the pipe instead of heating the joint directly. You’d then add filler metal to the joint and capillary actions will suck the melt into the joint.

3. Stainless Steel

Stainless steel requires a lot of heat to melt because it has a very high melting point. It’s also protected against corrosion because of its chromium content (at least 11%).

4. Brass

Brass is welded using an oxidizing flame and is made up of copper and zinc. It’s also highly thermally conductive and has a melting point of 1,710 degrees Fahrenheit so only a large nozzle can apply enough heat to melt it.

5. Cast Iron

Cast iron is an iron-based metal that contains more carbon than steel. It has a high melting point, so it needs an oxidizing flame. The hefty carbon content makes cast iron difficult to weld without creating cracks or problematic hard spots.

6. Nickel Alloys

Nickel-based alloys can be welded without significantly affecting their corrosion resistance or mechanical properties. Nickel alloys are formed mostly of nickel with varying amounts of chromium and molybdenum. Nickel alloys should not be welded using oxy-acetylene welding. TIG welding or MIG welding should be used instead.

What Are the Materials That Cannot Be Use in Gas Welding?

Nonmetals, including composites, woods, and plastics, cannot be gas welded. And even weldable metals have limitations. Dissimilar metals typically cannot be gas welded to one another. For example, aluminum and steel, aluminum and copper, or titanium and steel melt at significantly different temperatures, so they can’t form a proper weld pool together.

How Durable Is a Gas Weld?

A good weld can be as strong as the metal parts it joins. However, that assumes it fully penetrates the joint. If the joined parts butt too closely together or are simply too thick, the weld may not complete properly. Gas welds also need to be air-cooled to be strong. If quenched in water or other fluids, the weld will become brittle.

How Much Does Gas Welding Machine Cost?

Welding machines are relatively cheap but vary in quality. Basic DIY systems go for approximately $300 while high-end ones can range all the way up to approximately $5000.

How Long Does a Gas Welding Machine Last?

Most welding machines will easily last 10 years with regular use. If regularly maintained, though, they should survive 20 years or more.

What Are the Advantages of Gas Welding?

Gas welding has many advantages, the most notable of which is its low cost. Other advantages of this technology are:

- It can join parts made of both ferrous and non-ferrous metals.

- It does not require electricity which means it can be used in isolated areas.

- It does not require high-rated skills.

- Welding equipment is portable, requiring only a fuel and oxygen tank, control valves, and a torch.

What Are the Disadvantages of Gas Welding?

The main disadvantage of gas welding versus other forms is that it is limited to relatively thin sections of metal. Other disadvantages of gas welding are:

- It usually requires post-processing if aesthetics are important.

- The heat affects the mechanical properties of high-strength steel.

- It is slower than other methods because it doesn’t get as hot.

- Its lack of flux shielding can cause weld defects.

What Are the Side-Effects of Gas Welding?

Gas welding is a hazardous activity by nature and can cause harmful side effects. One of the most prominent is a respiratory illness. Welding can lead to asphyxiation when performed in a confined space. Other possible health side effects are:

- Skin burns

- Eye burns

- Coughing/occupational asthma

- Tight breathing

- Dizziness

- Fatigue

Is Gas Welding Hot Enough To Twist and Warp Metal?

Yes, gas welding can warp and twist metal. Metals such as copper and aluminum can warp when too much heat is added during welding. More specifically, warping occurs where there is rapid (and thus uneven) heating and cooling of the welded metal.

Can Gas Welding Take Longer Than Laser Welding?

Yes, gas welding takes longer than laser welding. Gas welding is limited by the heat at which the gasses burn. Laser welders can reach 200 inches per minute whereas gas welding is far slower.

What Is the Difference Between Gas Welding and Arc Welding?

The difference between gas welding and arc welding is that the former heats metal by burning gas while the latter creates heat through an arc of electricity. This makes gas welders portable but also arguably more dangerous.

How Xometry Can Help

We provide a wide range of manufacturing capabilities and services here at Xometry, including CNC machining, 3D printing, laser cutting, and of course, gas welding as a post-processing operation. If you’d like to find out more about gas welding or get a free no-obligation quote, reach out to a Xometry representative today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.