Xometry instantly quotes laser tube cutting and tube bending projects. Quotes through the Xometry Instant Quoting Engine will always assume normal to surface cuts to reduce lead time and cost for your projects. If you are uncertain what a normal to surface cut is, click here to learn what they are and how they look.

Normalizing tube cuts in your model may seem like a hassle, but it only takes a few tools! This guide will teach you the best method for normalizing mitered cuts on rectangle tubing.

If you are looking to normalize mitered cuts on round tubing, this method won't quite work. Review Designing Normalized Mitered Cuts on Round Tube to learn two great methods.

Before You Start

In this article, we’ll be referring to both rectangle and square tubing collectively as rectangle tubing (since a square is a rectangle). Don’t be mistaken, this method normalizes miters on both rectangle and square tube.

Also, it's crucial to make sure your rectangle tube model has corner radii. This guide assumes your model has coroner radii as it is industry standard for rectangle tubing to be manufactured with rounded corners.

1. Make a Ruled Surface

Start by clicking the Ruled Surface tool from the Surfaces tab. Before making selections, set the “Type” to “Normal to Surface”. This will make the ruled surface extrude normal to the surface of the selected edge.

Next, select the inside edge of your mitered cut. This selection will be recorded as your “Edge Selection” and a yellow preview of your ruled surface should appear.

Then, input any distance greater than the thickness of your tube so that the ruled surface extrudes past the outside surface of the tube. If your ruled surface is extruding inwards, click the “Reverse Direction” icon to change the direction.

Before you finish, make sure "Options" is set to "Trim and Knit" to make your ruled surface one continuous surface. This is important for future steps.

Finally, click OK.

Pro Tip: If the ruled surface is not extruding outward, select your edge from the “Edge Selection” and click “Alternate Face”. This will change the face the tool is referencing.

2. Delete Faces

Now that we have our ruled surface, click the Delete Face tool in the Surfaces tab. Before making selections, make sure “Options” is set to “Delete”.

Next, select all faces of your tube EXCEPT for the outside face. Make sure to select the faces of your rounded corners, they can be easy to miss.

Click OK. You should be left with a continuous outside surface of the tube and your ruled surface.

5. Thicken Surface

With the excess surfaces removed, click the Thicken tool in the Surfaces tab. Select the outside tube surface as the “Surface to Thicken”. Change the thickness direction until the feature is thickening inward. The yellow preview should be inside of your tube.

Enter the wall thickness of your tube and click OK.

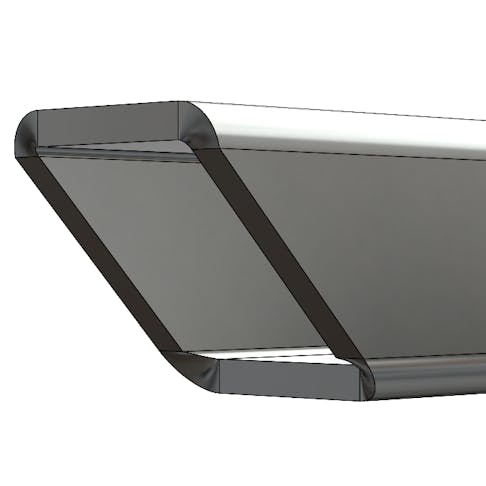

Congratulations! You have normalized your miter cut using the Trim Surface Method. This is what your project will look like post manufacturing.

FAQ

What is a normal to surface cut?

A normal to surface cut is a cut that is perpendicular to the surface of the tube. These cuts are industry standard and can reduce lead time and price of laser tube cutting projects. To learn more about normal to surface cuts, click here.

Do I need to model my cuts normal to surface?

No. But modeling can help you understand how your design will look after fabrication.

Why is my Ruled Surface not normal to surface?

Make sure the “Type” is set to “Normal to Surface”. If the “Type” is correct, select the problematic edge and click “Alternate Face” until the ruled surface is extruding in the correct direction.

Can I use this method for normalizing mitered cuts on round tubes?

No. Methods to normalize cuts on round tubes are similar to rectangle tubes, but have some key differences. Review Designing Normalized Mitered Cuts on Round Tube to learn two great methods.

How do I know if my cuts are normalized?

Rotate your model and imagine if a laser could make every cut perpendicular to the outside surface of the tube. If you still aren’t quite sure, take a look at our tube gallery here.

How Xometry Can Help

Normalizing tube cuts doesn’t have to be a hassle. We hope these methods help you understand how miter cuts on rectangle tubing will look after fabrication. If you want to make sure you’ve followed these steps correctly, review our gallery here.

Now that your tube cuts are normalized, upload your laser tube projects to our Instant Quoting Engine today!

If you have any feedback about the method discussed or have methods of your own you’d like to share, email us at support@xometry.com!

Xometry's Tube and Fabrication Services

Laser Tube Cutting Services

Tube Bending Services

Custom Online Weldment Services by Xometry