Types of 3D Printing Metals

A variety of metal 3D printing options through laser sintering and binder jetting are available for an instant online quote. If you do not see the material stock you are looking for, please choose "Custom" under the material drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required.

Direct Metal Laser Sintering (DMLS) 3D Printed Materials

Also known as Selective Laser Melting (SLM) or Direct Metal Laser Melting (DMLM). Material spec sheets are for reference only.

Learn more about our metal 3D printing services

- 3D Printed Aluminum AlSi10Mg: Lightweight aluminum alloy, AlSi10Mg. A great alternative to machining or casting complex geometries. (View spec sheet)

- 3D Printed Stainless Steel 17-4: Fully-Dense 17-4 PH stainless steel metal, hardness 40 HRC, heat treatable. (View spec sheet)

- 3D Printed Stainless Steel 316/L: Fully-dense 316L stainless steel metal, superb corrosion resistance, meets requirements of ASTM F138 (View spec sheet)

- 3D Printed Maraging Steel MS1: A heat-treatable tool steel that can be post-hardened to more than 50 HRC to achieve excellent hardness and strength. (View spec sheet)

- 3D Printed Inconel 625: A heat and corrosion-resistant nickel alloy offering high oxidation resistance. (View spec sheet)

- 3D Printed Inconel 718: A heat and corrosion-resistant nickel alloy ideal for high-temperature applications. It offers good tensile, fatigue, creep, and rupture strength at temperatures up to 700 °C (1290 °F). (View spec sheet)

- 3D Printed Titanium Ti64: A lightweight alloy with excellent mechanical properties and corrosion resistance used in high-performing engineering applications as well as biomedical implants. (View spec sheet)

Gallery of Select 3D Printed Metals

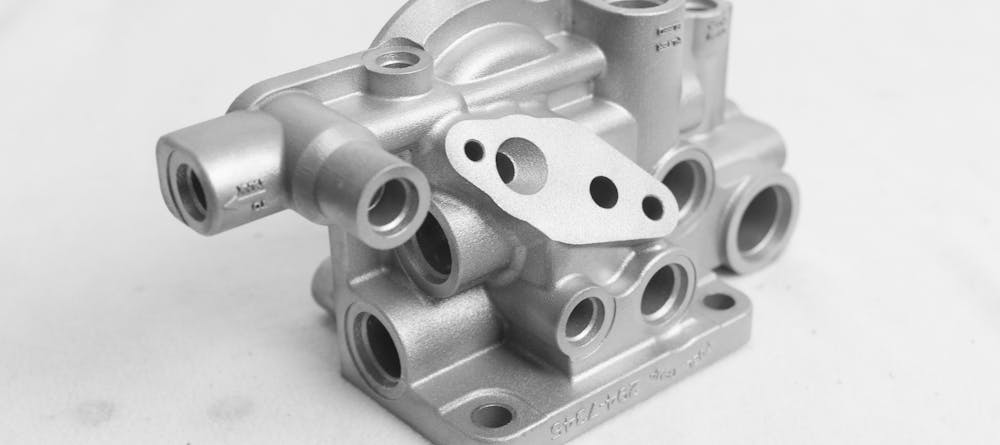

Lightweight aluminum alloy, AlSi10Mg. A great alternative to machining or casting complex geometries. (View spec sheet)

Fully-Dense 17-4 PH stainless steel metal, hardness 40 HRC, heat treatable. (View spec sheet)

Fully-dense 316L stainless steel metal, superb corrosion resistance, meets requirements of ASTM F138 (View spec sheet)

A matrix metal composite material composed of 60% 420 stainless steel and 40% bronze infiltrant. (View spec sheet)

Metal Binder Jetting 3D Printed Metals and Metal Composites

ExOne's Binder Jet Metal 3D printing instantly quotes online with its premiere material 420i.

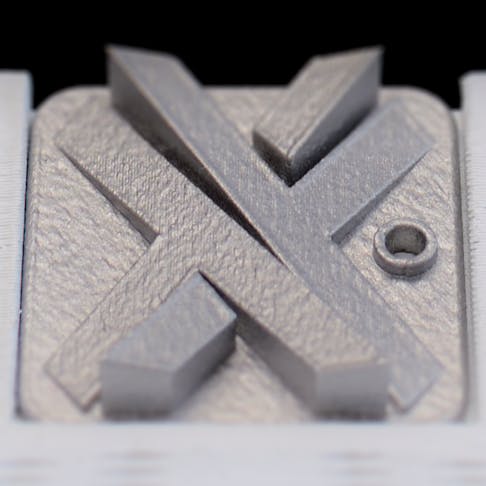

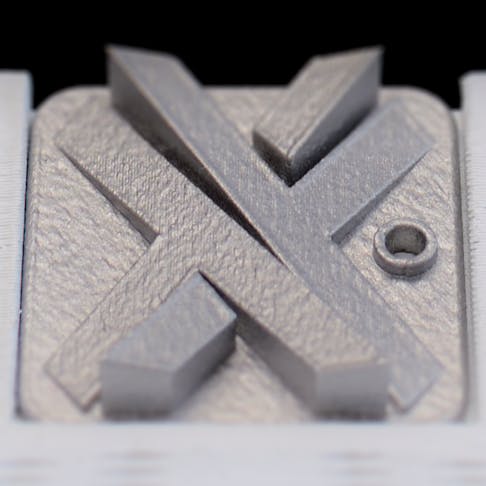

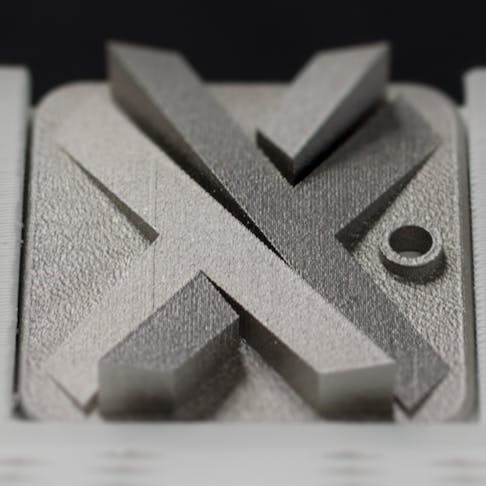

- X1 Metal 420i (Stainless Steel Infiltrated with Bronze): A matrix metal composite material composed of 60% 420 stainless steel and 40% bronze infiltrant. This material offers good mechanical properties and offers excellent wear resistance. 95%+ density. Properties compare similarly to 4140 steel. Available in six finishes: Zirblast (Standard), Tumble Polished, Medieval Pewter, Damascus Steel, Antique Bronze, and Wheat Penny. (View spec sheet)

- X1 Metal 316i (Stainless Steel Infiltrated with Bronze): A matrix metal composite material composed of 60% 316 stainless steel and 40% bronze infiltrant. This material offers good mechanical properties and offers excellent wear resistance. 95%+ density. 316i is more corrosion resistant than 420i. Available in six finishes: Zirblast (Standard), Tumble Polished, Medieval Pewter, Damascus Steel, Antique Bronze, and Wheat Penny. (View spec sheet)

- 316L SS (single alloy): 98%+ dense 316L stainless steel metal, superb corrosion resistance, and excellent feature details. Zirblast finish. (View spec sheet)

- 3D Printed Single Alloy 17-4PH Stainless Steel

- 3D Printed Single Alloy 304L Stainless Steel 97% dense

- 3D Printed Single Alloy M2 Tool Steel

- 3D Printed Single Alloy Inconel 718, 99.2% dense

- 3D Printed Tungsten-Bronze metal composite, 97% dense

- Other 3D printed binder jet metals. Please reach out to a Xometry sales associate for inquires.

Finishes and Post-Processing Options

We offer a wide range of surface finishes applicable to these plastics including:

- Sanding

- Media Tumbling

- Media Blasting

- Vapor Smoothing

- Painting

- Dyeing

- Nickel Plating (SLS)

- Custom: we evaluate custom requests on a case-by-case basis