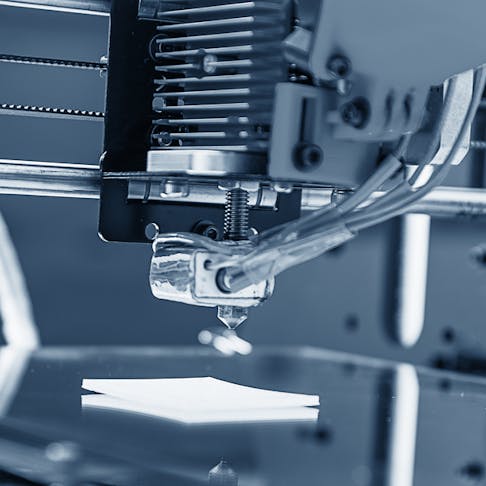

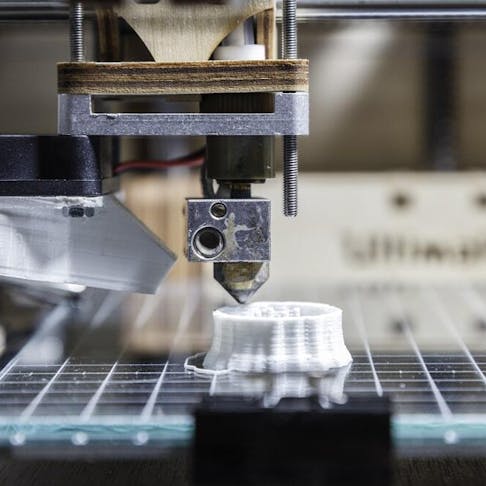

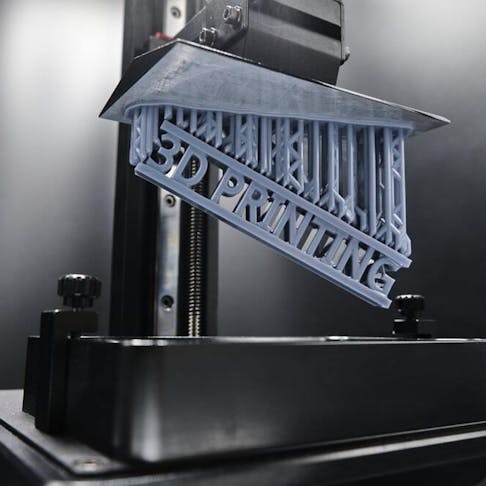

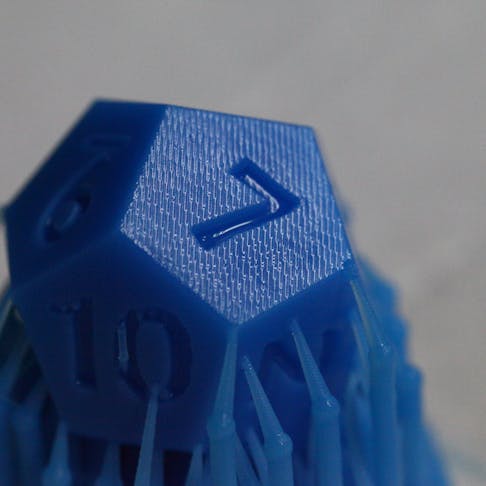

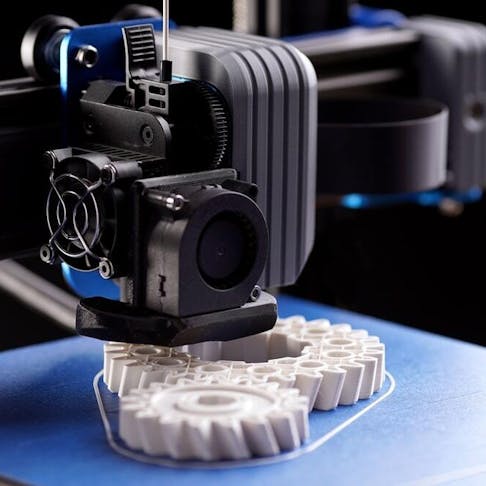

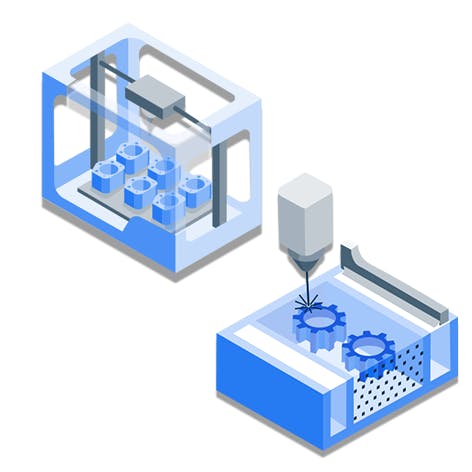

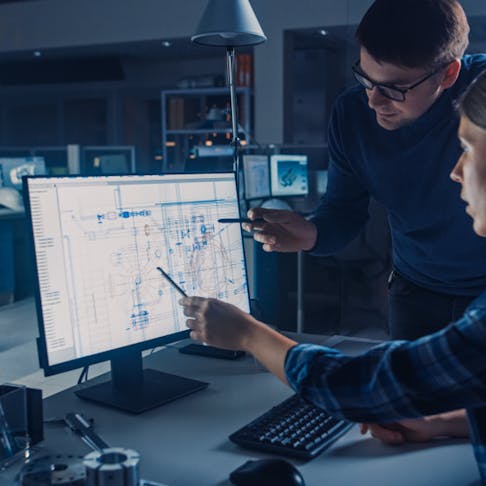

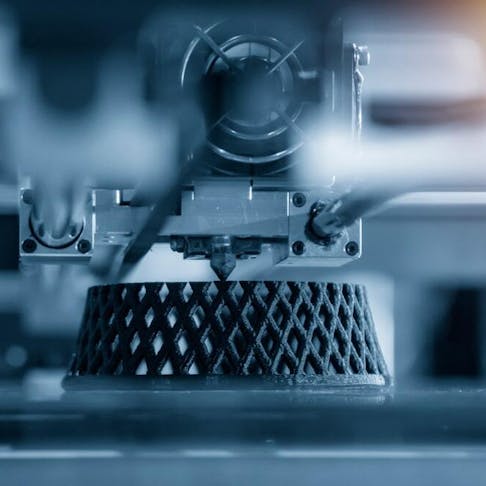

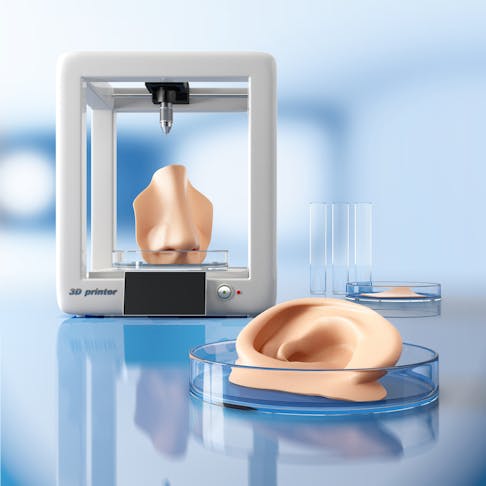

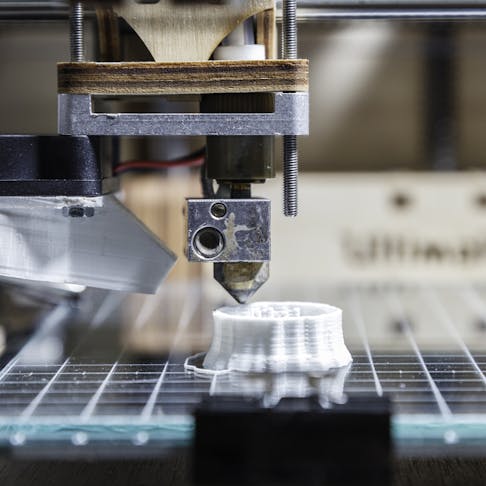

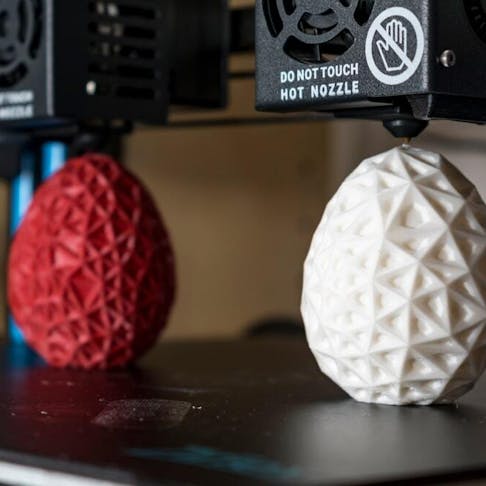

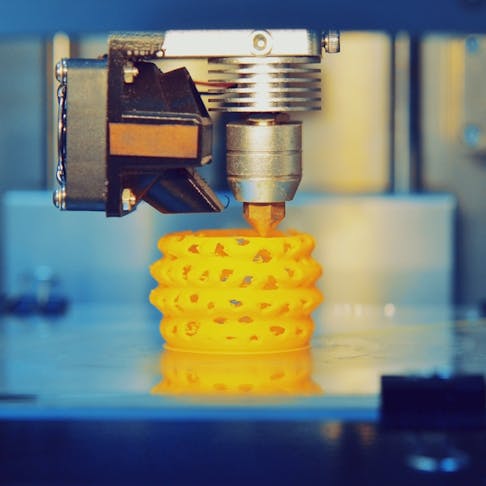

3D Printing Design

The latest news, trends, and manufacturing design tips for additive manufacturing.

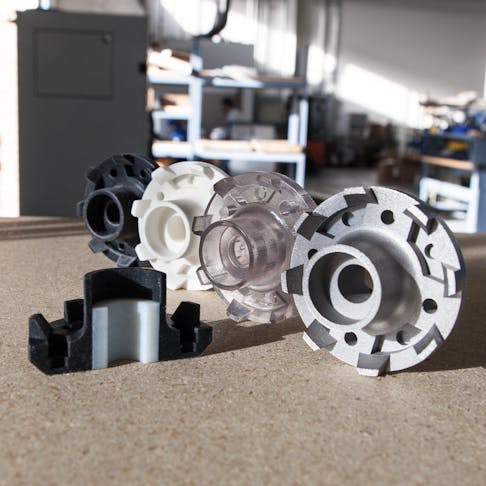

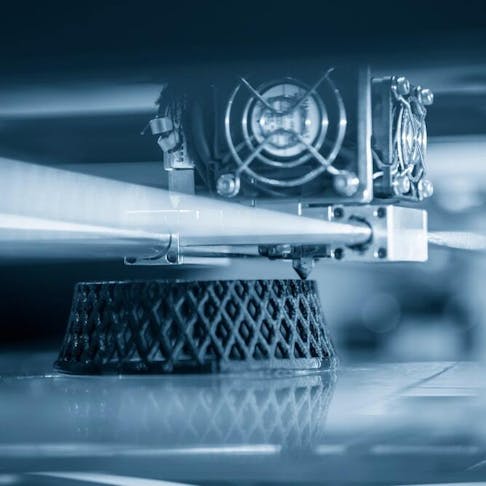

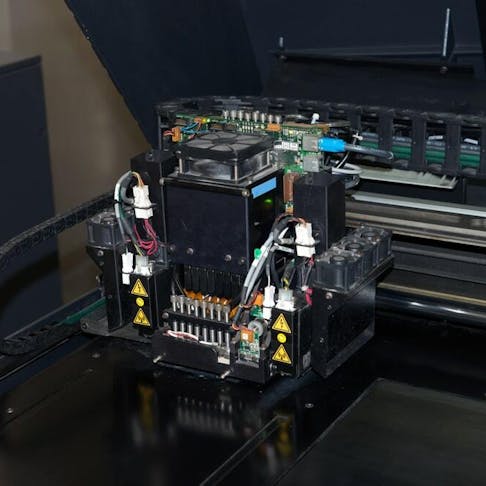

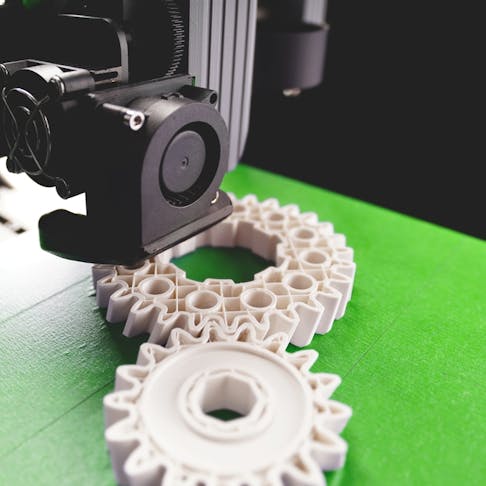

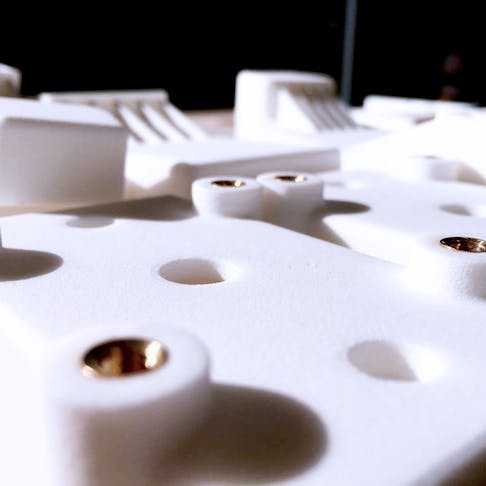

Binder Jetting vs. Material Jetting 3D Printing — What's the Difference?

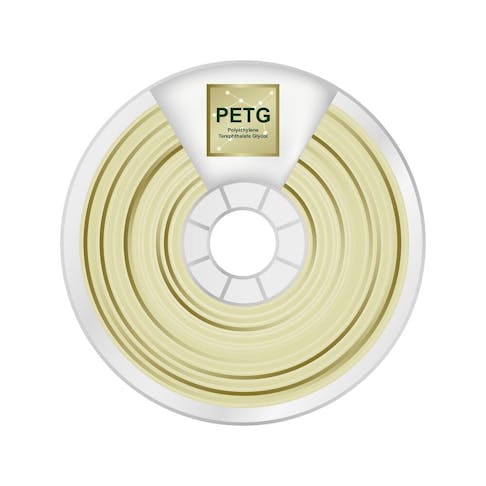

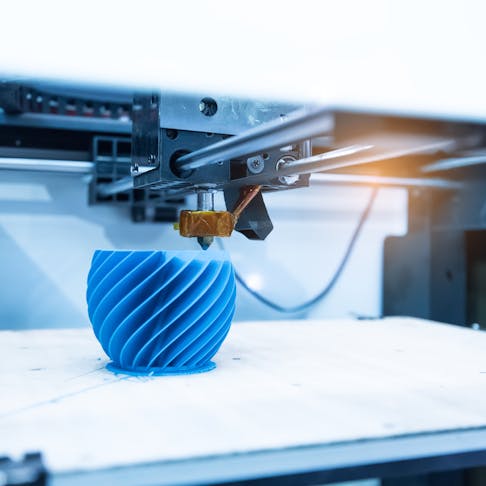

Vapor Smoothing PETG: Definition, Purpose, How It Works, Advantages, and Examples

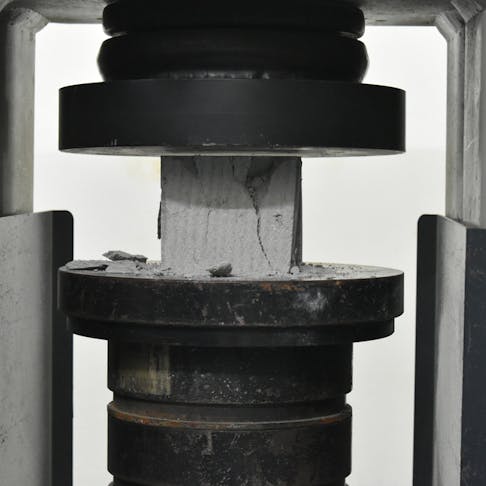

Bulk Modulus: Definition, How It Works, Formula, Examples, and Benefits

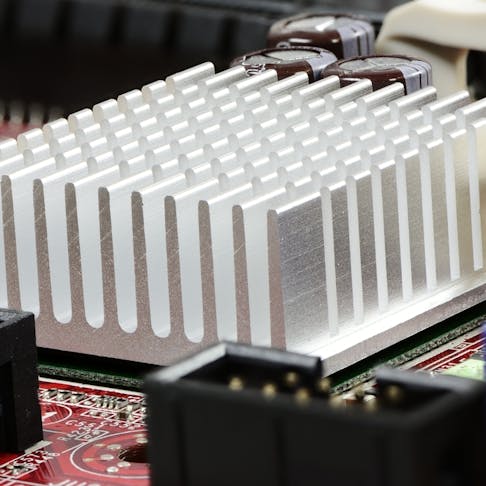

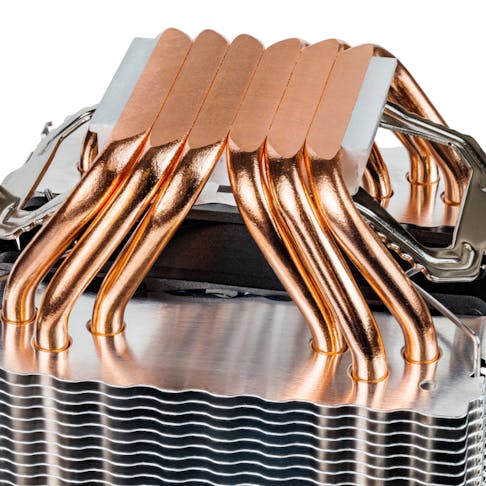

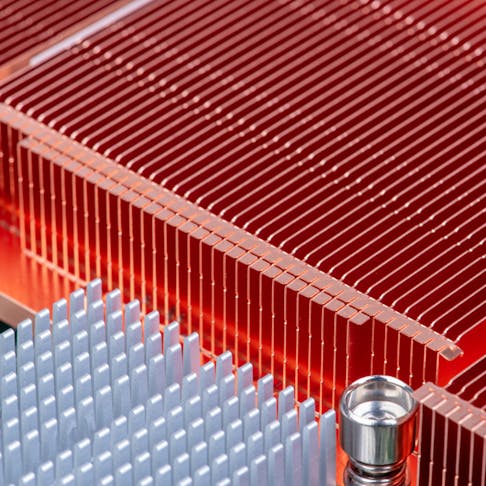

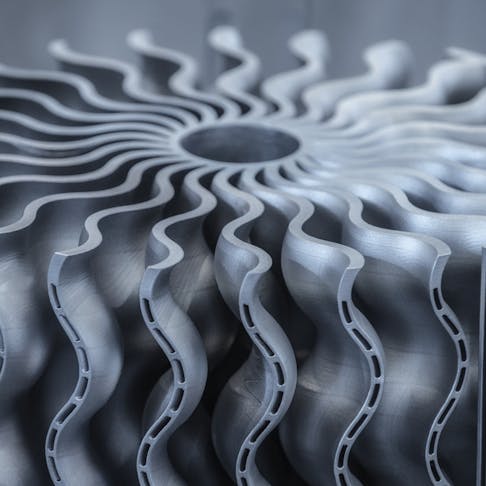

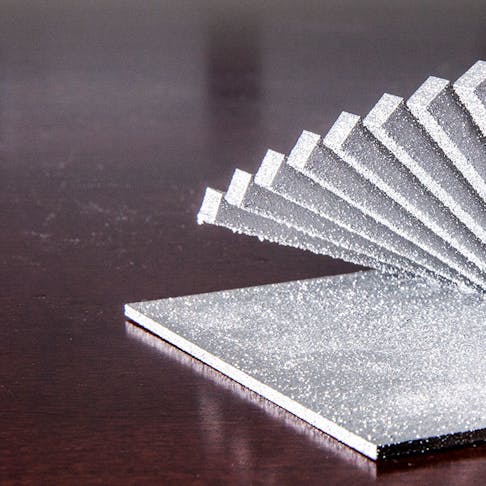

Heat Spreader: Components, Types, Applications, and Factors That Affect Its Performance

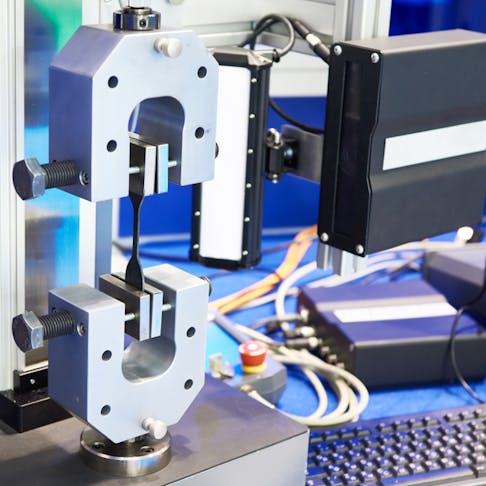

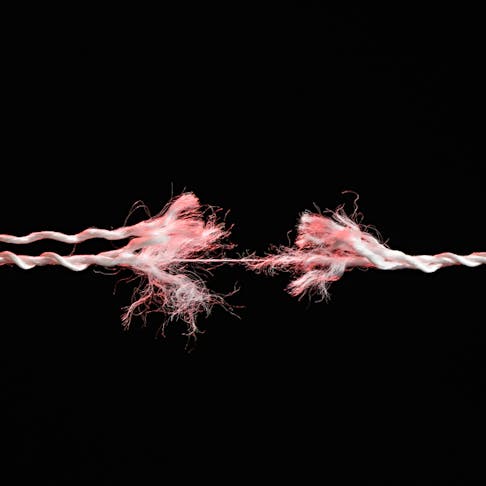

Tear Strength: Definition, Relation to 3D Printing, Formula, Unit, and How to Measure

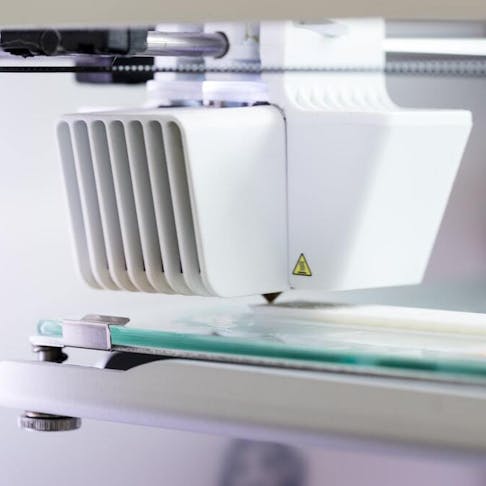

Heat Sink: Definition, How It Works, Components, Types, and Applications

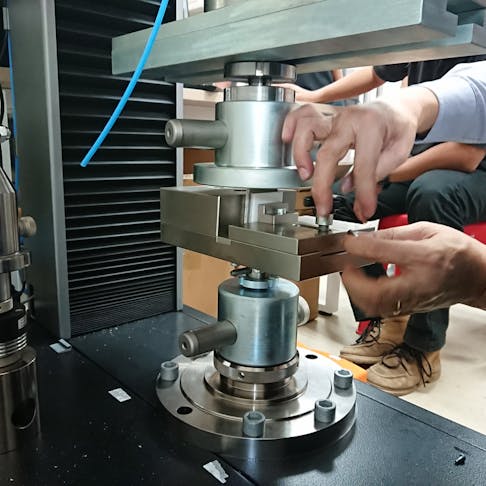

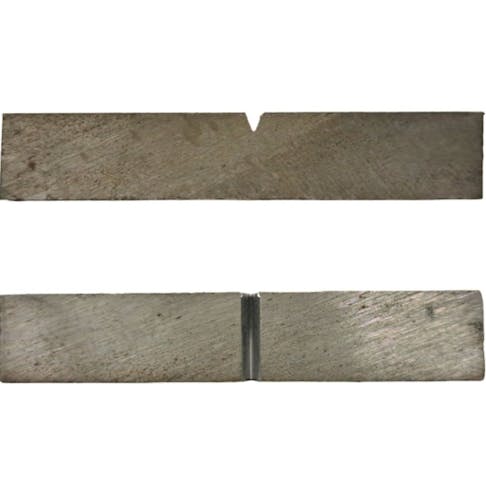

Ductility Test: Definition, Purpose, Applications, and How Does It Work

Heat Pipe: Definition, Components, Types, Applications, and Factors That Affect Its Performance

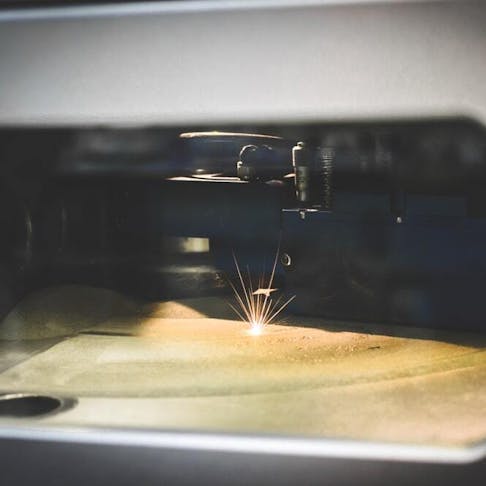

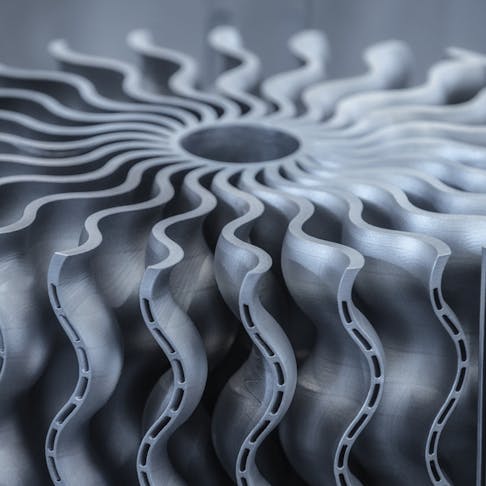

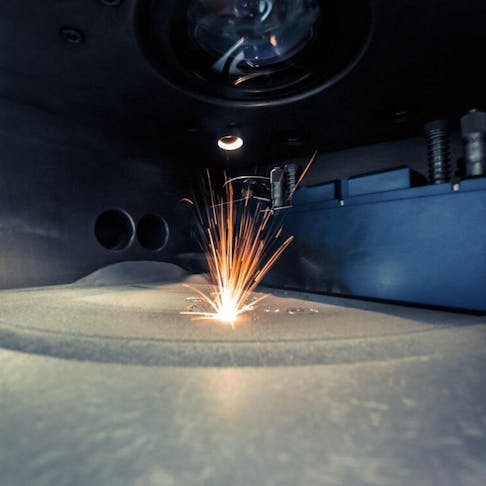

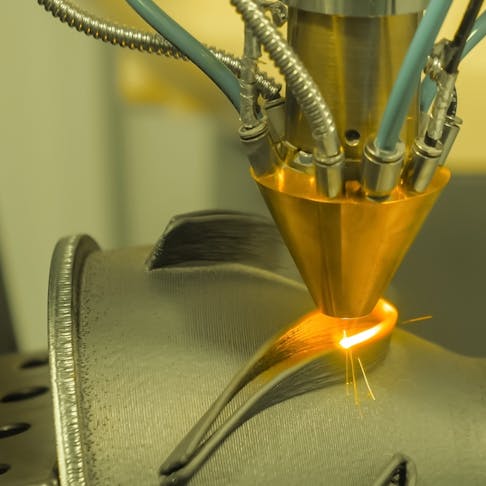

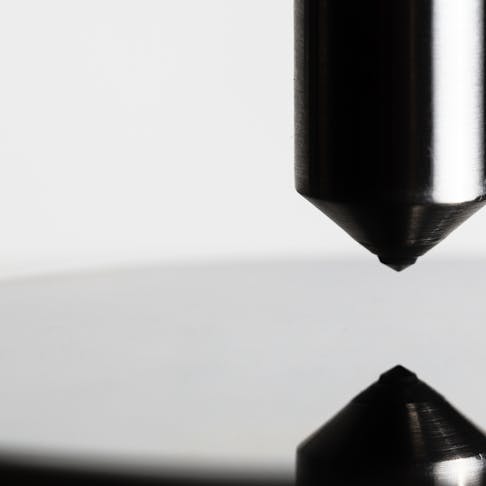

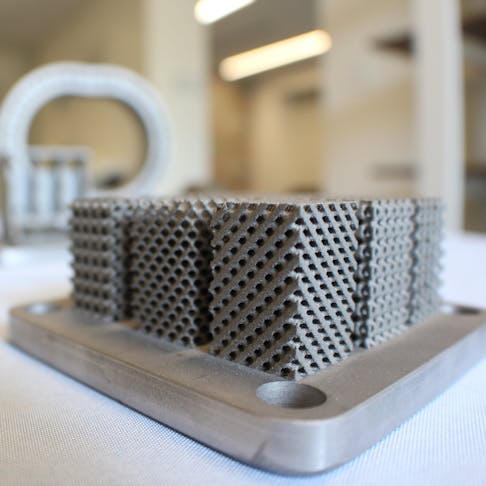

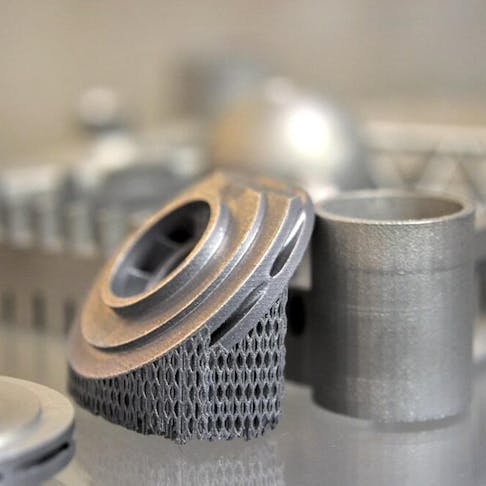

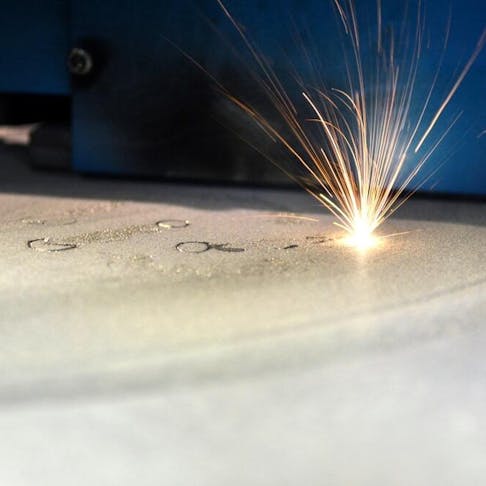

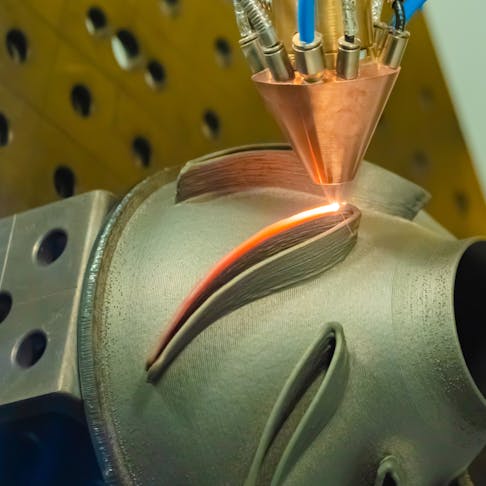

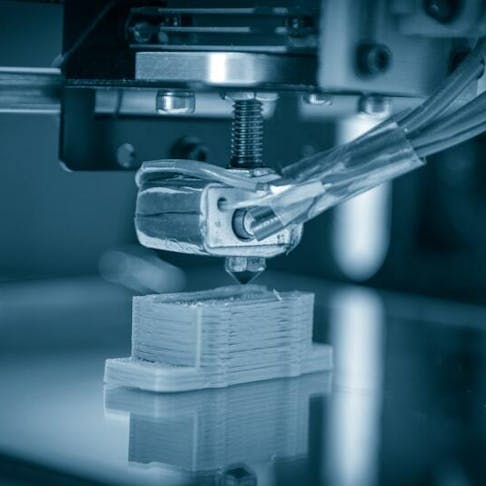

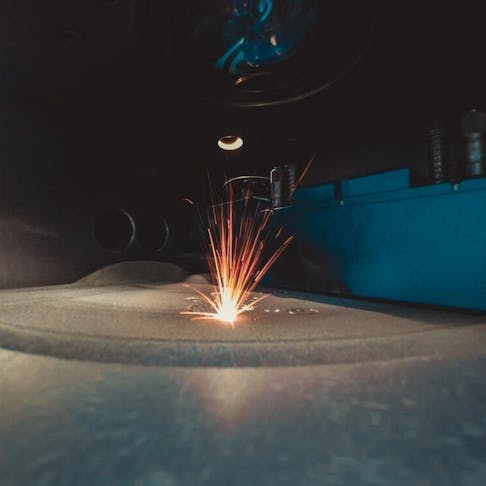

Direct Energy Deposition (DED): Definition, Examples, How Does It Work, Advantages and Disadvantages

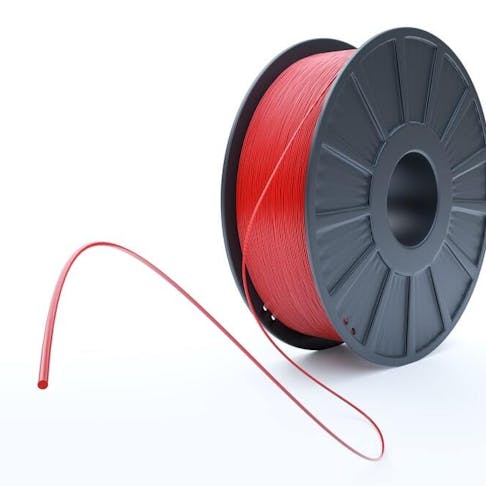

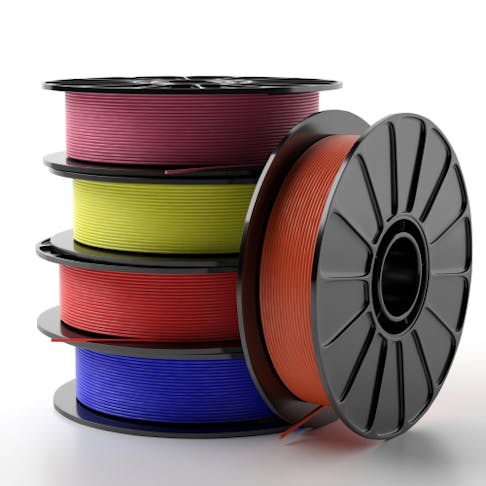

All About Magnetic Iron 3D Printing Filament: Materials, Properties, Definition

6 Things to Consider When Choosing the Right Heat Sink for Your Application

Vapor Smoothing PLA: Definition, Advantages, and Disadvantages in Laser Cutting

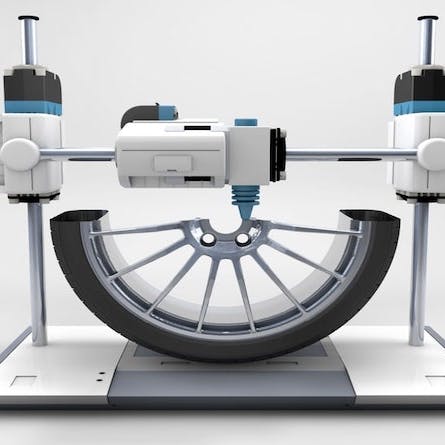

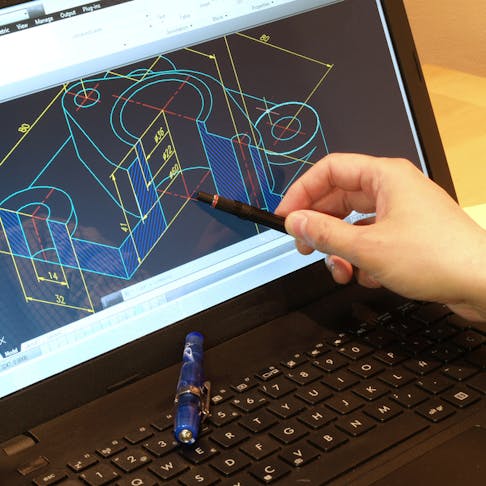

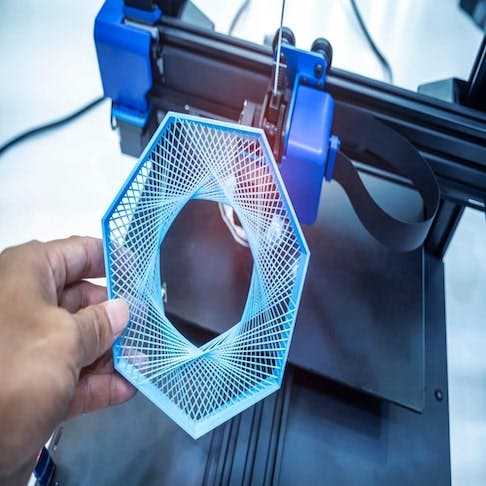

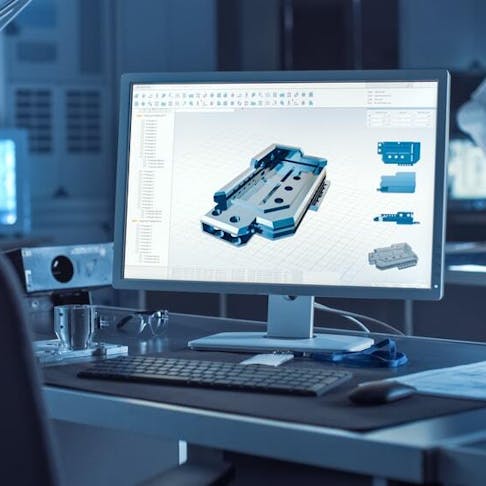

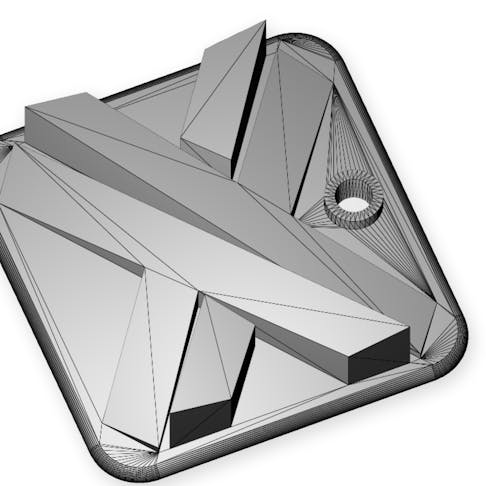

eBook: How to Prepare a File for 3D Printing

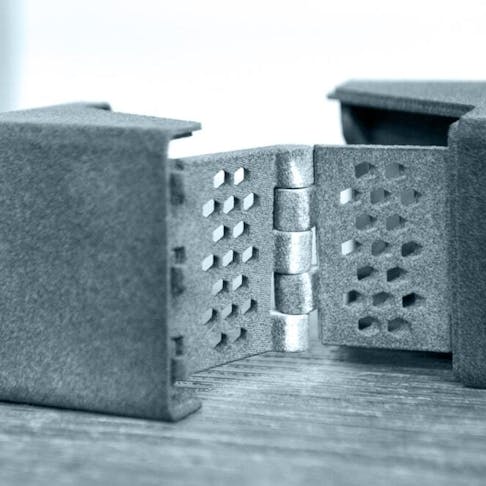

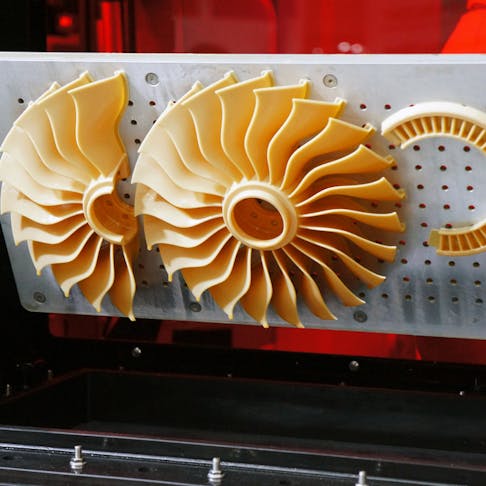

Exploring Different Types of Sintering Techniques: A Comprehensive Overview of 13 Methods

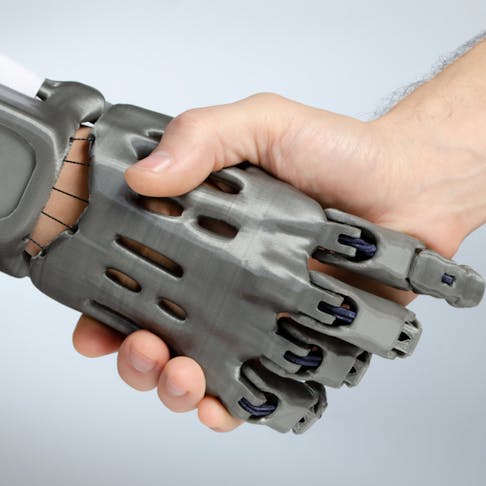

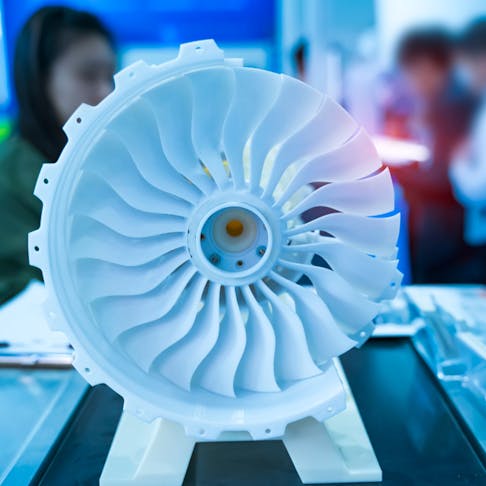

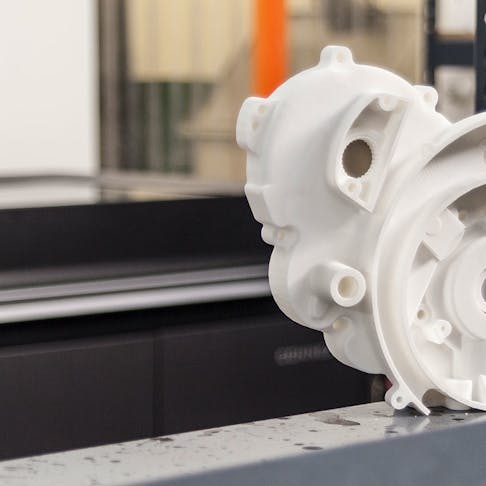

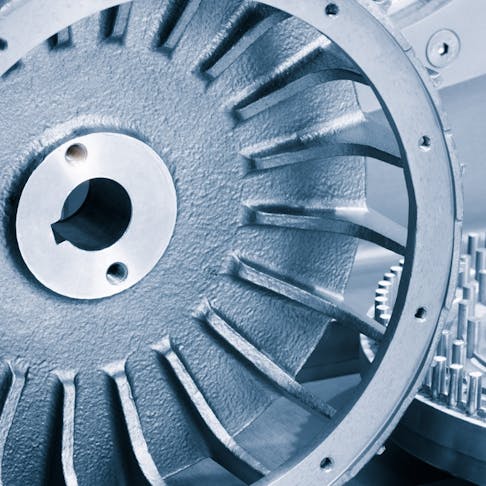

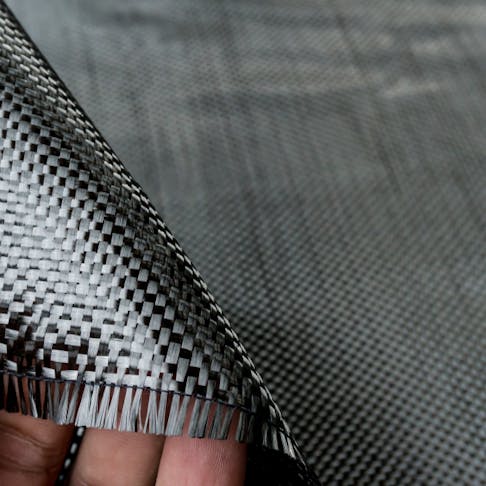

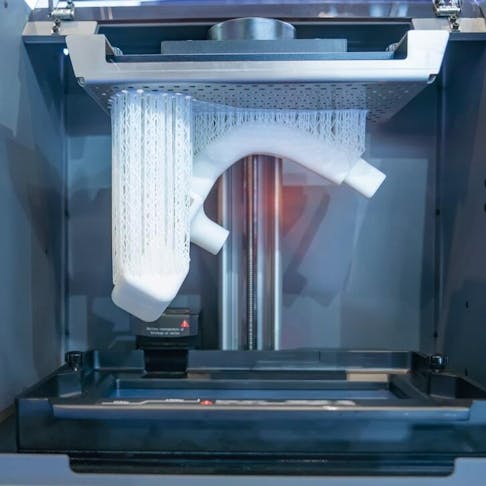

3D Printing Technology for Aerospace Parts: Benefits and How the Technology Evolved

All About Conductive PLA 3D Printing Filament: Materials, Properties, Definition

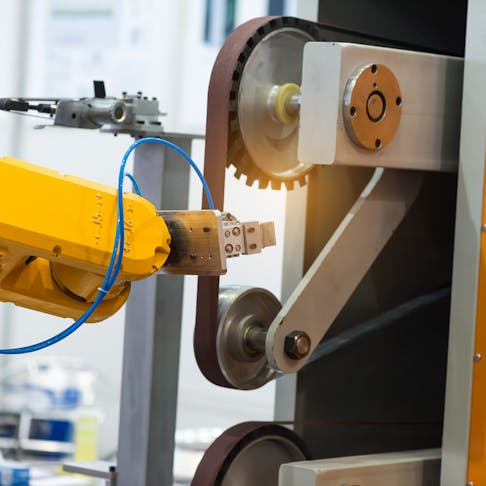

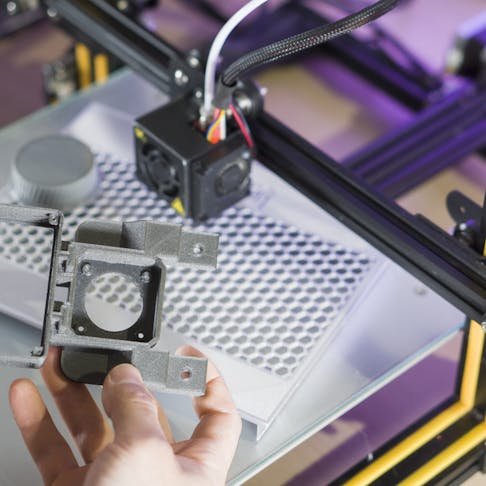

Metal 3D Printing Technologies Are Rapidly Evolving: Here's How You Can Take Advantage Without Risk

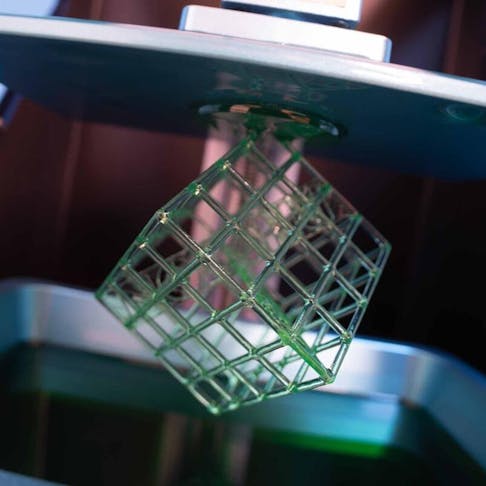

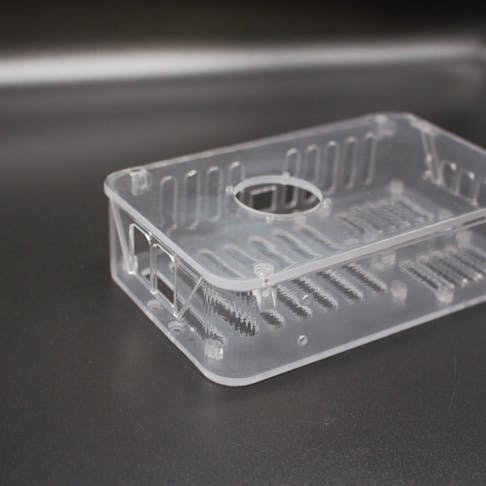

Stereolithography (SLA) Quick Clear Now Instantly Quotes for Faster 3D Printed Transparent Parts

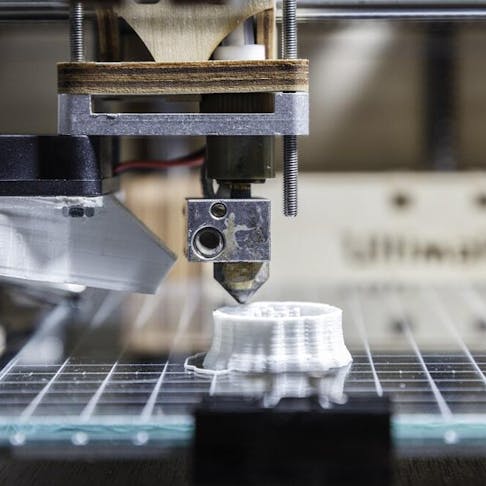

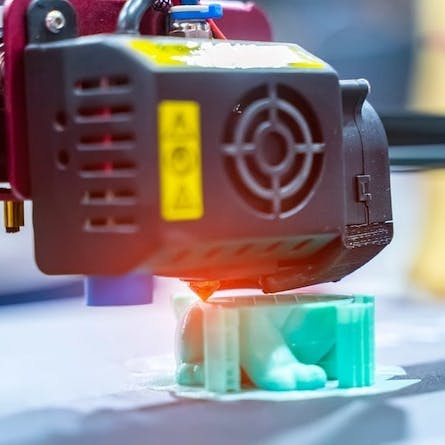

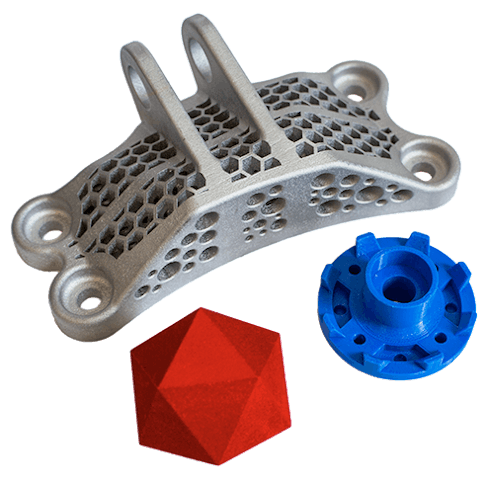

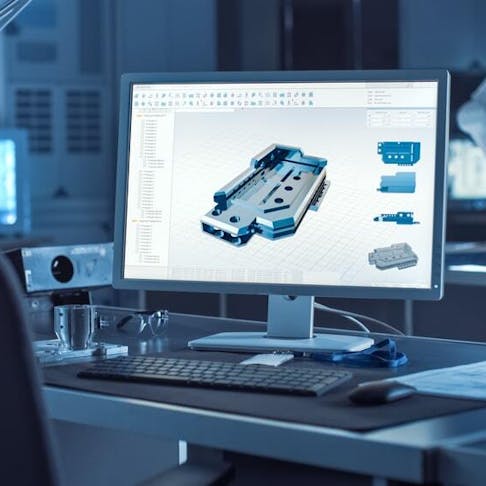

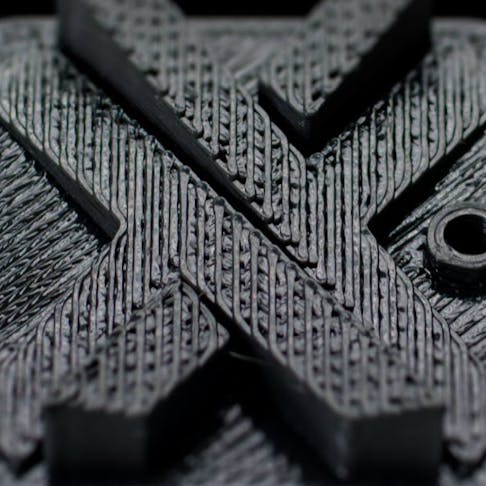

3D Printing Process & Material Design Guide