3D Printing in Medicine and Healthcare

3D printing, or additive manufacturing, dates back to the 1980s. Since its invention, it has found uses in a wide range of industries, specifically in the medical and healthcare industry where it has shown great potential. It has found uses in the development of replacement organs, prosthetics, and medical equipment, among other applications.

In this article, we’ll take a closer look at the different uses of additive manufacturing in the medical industry. We’ll discuss the advantages, disadvantages, and challenges associated with this technology in the medical industry, and also touch on FDA regulations concerning the safety of additive manufacturing products used in the medical industry. Lastly, we’ll discuss other current and potential applications for additive manufacturing.

What Is Medicine and Healthcare?

“Medicine and healthcare” is an umbrella term that refers to the procedures and practices related to the prevention, treatment, cure, and relief of abnormal conditions or the symptoms of diseases. It also includes the investigation or study of mental and physical well-being.

The practice of “medicine” is the term that is used to refer to the practice of preventing, diagnosing, and treating illnesses and injuries. It involves a wide range of activities, from prescribing medications and performing surgeries to providing counseling and advice on healthy lifestyle habits.

"Healthcare" includes not only the activities and services related to the maintenance or improvement of people's health, the entire support structure for the professionals delivering that care, such as pharmacists and therapists — and the engineers designing and manufacturing the products used in the healthcare industry.

What Is 3D Printing in Healthcare?

3D printing is a manufacturing technique that differs from traditional methods by creating three-dimensional objects through an additive process. Instead of shaping raw materials through subtractive processes like grinding, carving, or machining, 3D printing builds objects layer by layer using materials like plastics, metals, and ceramics. These objects are generated from digital files, often derived from magnetic resonance imaging (MRI) or computer-aided design (CAD) drawings, offering flexibility for modifications as needed. The diverse range of 3D printers available in the market caters to both consumer and commercial-grade applications, allowing for the production of many different products.

3D printing in healthcare is often used to create intricate scaffolds that mimic the structure of human tissues or organs. These scaffolds provide a framework for cells to grow and adhere to, facilitating tissue regeneration.While 3D printing may not always be faster than traditional manufacturing techniques for every type of product, it can streamline the manufacturing of certain medical devices and components. Products based on patient-specific anatomy are on the rise, available both through large-scale manufacturers and point-of-care 3D printing facilities in healthcare settings. Patient-specific customization reduces the need for large-scale mass production and centralized manufacturing. It enables decentralized production in which parts can be printed where and when they are needed, potentially saving time and resources.

How Does 3D Printing Technology Help Medicine and Healthcare?

Today, 3D printing plays a significant role in the medicine and healthcare industry. Here are some specific ways in which it is helping:

- Personalized Prosthetics: 3D printing allows for the creation of customized prosthetics that perfectly match an individual's unique anatomy. Personalized prosthetics aim to provide better comfort and functionality.

- Surgical Planning and Practice: Surgeons can use 3D printed models to practice complex procedures before performing them on a patient. This reduces the risk of errors during surgery and improves outcomes.

- Medical Devices: Medical devices, such as surgical tools and implants, can be produced with 3D printing machines. This allows for greater precision and customization, leading to better outcomes for patients.

- Organ and Tissue Printing: Researchers are working on 3D printing organs, like livers and kidneys, and tissues, potentially creating a new approach to treating diseases and injuries.

- Pharmaceutical Printing: 3D printing can also be used to create customized medication dosages and formulations. It improves patient adherence and reduces side effects. For example, the FDA approved an epilepsy drug (Spritam) which is produced through 3D printers. The drug is printed layer by layer using the powdered drug. This makes the drug easier to dissolve than average pills.

- Medical Education: 3D printing allows for the creation of anatomical models that can be used in medical education to enhance understanding and learning.

How Does 3D Printing Drive Innovation in the Healthcare Industry?

3D printing has resulted in advances in the healthcare industry by enabling the fabrication of tailored, patient-specific solutions. It leverages patient data like MRI and CT scans to create personalized implants, prosthetics, and anatomical models. Additionally, 3D printing allows for the production of intricate, porous medical devices that integrate seamlessly with patient tissues.

This technology supports rapid prototyping, expediting the development of innovative healthcare solutions. Point-of-care manufacturing enhances surgical precision by producing real-time patient-specific models and surgical guides. It is also environmentally friendly, minimizing material waste through producing near-net shape.

What Is the Importance of 3D Printing in Healthcare?

The main goal and importance of 3D printing in healthcare is to improve patient care. This innovative technology tailors medical solutions, including devices, implants, and treatments, to individual patients. 3D printing enables the creation of complex, highly functional medical devices with intricate geometries that were previously not manufacturable. Furthermore, 3D printing's pharmaceutical innovations offer unique dosage forms and formulations, potentially revolutionizing personalized drug delivery. Patients may benefit from more effective medications with fewer side effects.

Rapid prototyping accelerates the development of cutting-edge healthcare solutions, providing quicker access to advanced treatments and devices. Point-of-care manufacturing, made possible by 3D printing, enhances surgical precision and reduces wait times for medical interventions, ensuring prompt and efficient patient care.

What Is the History of 3D Printing in Healthcare?

Throughout history, significant milestones have paved the way for 3D printing's impact on healthcare. In the 1860s, François Willème pioneered a technique known as "photo sculpting," which laid the foundation for 3D printing. Photosculpting involves capturing multiple photographs of an object from different angles and then using these images to create a three-dimensional representation. Essentially, it was an early form of 3D modeling and visualization, setting the stage for later developments in 3D printing technology.

Fast forward to 1984, Charles Hull's stereolithography device ushered in modern 3D printing. In 2000, healthcare began harnessing this technology, while 2001 marked the first 3D printing of synthetic scaffolds for human bladder tissue. By 2008, the first 3D-printed prosthetic leg was a reality.

The journey continued with groundbreaking achievements, such as the 3D bioprinting of blood vessels in 2009, and the commercial launch of 3D human liver tissue in 2014. By 2019, scientists were bioprinting hearts and lung-mimicking air sacs, advancing cardiac and respiratory research. In 2020, FabRx introduced M3DIMAKERTM, revolutionizing personalized medicine production. The creators describe this device as the inaugural pharmaceutical 3D printer designed specifically for manufacturing unconventional medications.

In the mere forty years since the first simple three-dimensional objects were printed from an epoxy resin, 3D printing has advanced to being able to make customized pharmaceuticals and organs printed from living cells. The resulting transformation in patient care possibilities has reverberated through the entire healthcare system - and the future possibilities are nearly limitless.

What Are the Impacts of 3D Printing in Healthcare?

Listed below are the four key areas where 3D printing has made a significant difference in healthcare:

1. Implants

3D printing has revolutionized the production of implants, allowing for the creation of patient-specific devices. Whether it's dental, spinal, or hip implants, 3D printing allows precise designs and enables accurate manufacturing. This customization not only guarantees a better fit but also reduces the risk of complications, improving patient outcomes.

Surgeons can now rapidly produce complex implants, reducing surgery time and post-operative discomfort. The ability to swiftly produce custom implants addresses a persistent problem in orthopedics, where standard implants often fall short. Previously, surgeons had to perform invasive bone graft surgeries or manually alter standard-sized implants.

Depending on the type of implant, different materials can be used to print them. Some common materials include metals, such as titanium, which is then manufactured through DMLS (direct metal laser sintering) or SLM (selective laser melting). Other materials that can be used to create implants include bioceramics and polymers like PMMA, PEEK, and PEKK. SLS (selective laser sintering) can also be used to create custom-made implants from materials like nylon, PA (polyamide), and ceramics.

2. Prosthetics

The impact of 3D printing in healthcare is especially profound in the field of prosthetics. Traditional prosthetics can be costly and require extensive manual adjustments. With 3D printing, prosthetic limbs can be rapidly and cost-effectively customized to fit each individual's unique needs. Additionally, 3D printing enables the creation of prosthetic components with intricate designs and improved aesthetics. This transformation has been a game-changer for amputees, providing them with more accessible and advanced solutions. FDM (fused deposition modeling), DMLS, and SLM technologies are used to create prosthetics. Materials that can be used include metals, such as titanium, and thermoplastics like PLA, ABS, and polycarbonate.

Traditional prosthetics can be prohibitively expensive, with costs ranging from $1,500 to $8,000, often paid out of pocket. In contrast, 3D-printed prosthetics can be produced for as little as $50, making them significantly more accessible, especially for children who rapidly outgrow their prosthetics. The rapid production capabilities of 3D printing allow for a limb to be created within a day. Additionally, the ability to customize these prosthetics, allowing children to choose colors and styles, adds to their appeal.

However, 3D-printed prosthetics do come with their own set of challenges. Durability is a significant concern, particularly for prosthetics produced by non-professional volunteers using 3D printers. The use of thin layers of hot plastic in 3D printing makes these prosthetics more susceptible to breakage if subjected to improper forces. Volunteer printers may also lack the extensive training and expertise of professional prosthetists. Furthermore, many 3D-printed prosthetics are not FDA-tested and approved, raising safety and reliability concerns when compared to rigorously tested traditional prosthetics. There is also a learning curve for volunteer printers to master the printing process and regulate temperatures, which can result in errors.

Efforts are underway to overcome these challenges. Collaborations between volunteers and engineers have led to innovations like the use of more durable materials such as Filaflex. While it may cost closer to $2,000, this represents a compromise between cost and durability.

3. Surgical Tools

3D printing has ushered in a new era of specialized surgical tools. Surgeons now have access to instruments tailored to specific procedures or individual patient anatomy. This level of customization reduces the risk of errors, minimizes tissue damage, and accelerates patient recovery. Surgical guides and templates produced through 3D printing assist in precise incisions and implant placement. This technology streamlines surgical processes and significantly benefits both patients and medical professionals. FDM (fused deposition modeling) 3D printing is well-suited for cost-effective, iterative prototyping, allowing for design optimization of tools. Some surgical tools can then be produced through metal 3D printing (through DMLS or SLM) or using such polymers as PEEK, PMMA, and PC as materials (FDM).

4. Anatomical Replicas

3D printing has transformed medical training and pre-surgical planning through the creation of anatomical replicas. These replicas, generated from patient imaging data, provide medical practitioners with tangible models for practice and surgical strategizing. Surgeons can simulate complex procedures and refine their techniques using these 3D-printed models, improving their skills and confidence. As a result, surgeries are more precise and efficient, reducing risks and post-operative complications. FDM (fused deposition modeling) printers excel at producing simple surgical models without the need for intricate details or high levels of complexity. SLA (stereolithography) is also used to produce anatomical models from different types of resins.

One significant advantage is the ability to rapidly make precise design adjustments to medical equipment and surgical tools based on feedback from surgeons. This allows doctors to test and improve the design of surgical tools before producing the final version. For more information, see our guide on 3D Printing in Prosthetics.

How Does the FDA Regulate 3D Printers and Printed Products Made for Medical Uses?

The FDA regulates 3D printing in medicine and healthcare in a similar way to other medical devices. However, the agency doesn’t regulate the 3D printers themselves. Rather, they regulate the medical devices the printers produce and the manufacturing processes involved in creating those products. The FDA's primary aim is to ensure that 3D-printed medical devices and products are safe, effective, and of high quality for patients.

The regulatory review process required depends on the product type, intended usage, and potential risks associated with it. These are classified based on risk level into one of three categories. Low-risk devices fall under Class I, moderate-risk devices under Class II, and high-risk devices under Class III. The classification of a device determines the level of regulatory scrutiny required.

While there is currently no specific FDA guidance for 3D printing in the drug or biologic domain, any products in these domains are still regulated by other existing oversight pathways through the FDA's Center for Drug Evaluation and Research, or the Center for Biologics Evaluation and Research.

Little formal management exists for medical 3D printing outside FDA regulations. Medical boards on the state level may have some form of oversight when patients are at risk from, let’s say, a specific 3D printing provider, but they typically only react to complaints rather than proactively investigate. Thus far, the majority of FDA-reviewed products that have been created through 3D printing have been medical devices like orthopedic implants, with over 100 such products having undergone review. For more information, see our guide on 3D Printing Types.

What Are the Advantages of 3D Printing in Medicine and Healthcare?

The adoption of 3D printing in healthcare offers multiple advantages, such as:

1. Adaptable Design

3D printing enables adaptable and patient-specific design. Medical devices, implants, and prosthetics can be customized to match the precise anatomies and needs of individual patients.

2. On-Demand Printing

Healthcare providers can employ 3D printing for the on-demand manufacturing of medical components and devices. This reduces the need for large inventories and ensures that products are readily available when required.

3. Fast Prototyping

3D printing facilitates rapid prototyping of new medical devices and innovations. This accelerates the development process, allowing for quick testing and refinement of ideas before they reach the clinical stage.

4. Rapid Production and Design

Traditional manufacturing processes can be time-consuming, whereas 3D printing allows for swift production and design iterations. This is crucial in emergencies and when addressing urgent medical needs.

5. Decreased Waste

3D printing generates minimal waste compared to subtractive manufacturing methods. This eco-friendly aspect contributes to reducing the environmental footprint of healthcare production.

6. Cost

3D printing can be cost-effective, especially when producing complex, customized medical devices. It reduces the cost of labor, materials, and tooling, making healthcare more accessible.

7. Parts That Are Sturdy and Light

3D printing allows for the creation of parts that are both sturdy and lightweight, a crucial advantage in applications such as orthopedics and aerospace medicine. This results in improved patient comfort and mobility.

8. Environmentally Responsible

3D printing's efficiency in material use and reduced waste aligns with environmental sustainability goals. Its minimal environmental impact makes it a responsible choice for healthcare manufacturing.

9. Easy Access

As 3D printers become more affordable and accessible, healthcare facilities can integrate this technology into their operations. It guarantees that even smaller clinics and hospitals can benefit from its advantages.

10. Healthcare Innovation

3D printing encourages innovation in the healthcare sector. It fosters the development of novel medical solutions, from customized surgical tools to cutting-edge prosthetics, advancing patient care and treatment outcomes.

11. Improved Visualization

Create detailed models of complex anatomical structures that may be difficult to visualize using traditional 2D images. This can aid in the diagnosis of illnesses and the planning of surgical interventions.

12. Reduced Surgical Time

Providing surgeons with a 3D-printed model of a patient's anatomy prior to surgery allows them to better plan and rehearse the procedure. This can lead to shorter surgical times, which reduces the risk of complications and improves patient outcomes.

13. Increased Efficiency

Streamlines the production of medical devices, prosthetics, and implants. This reduces the time and cost associated with traditional manufacturing methods, while also improving the quality and precision of the final product. However, individualized products may take more time than ‘one-size-fits-all’ items, like surgical equipment, for example; however, 3D printing is still way faster and more cost and production efficient than conventional methods.

14. Innovation

Allows for rapid prototyping and testing of new medical devices and treatments, which can accelerate the development of innovative solutions for patients.

What Are the Disadvantages of 3D Printing in Healthcare?

Here are several key disadvantages of 3D printing in the healthcare sector:

- The range of materials suitable for 3D printing in healthcare is somewhat restricted compared to the choices available for traditional manufacturing methods. While there is continuous research into expanding material options, certain medical-grade materials may still be unavailable for 3D printing.

- The regulatory approval process for 3D-printed medical devices and implants can be complex and time-consuming. Ensuring that 3D-printed medical products meet safety and efficacy standards requires thorough validation and testing.

- Maintaining consistent quality in 3D-printed medical products can be challenging. Variability in print quality or material properties may impact the reliability and safety of medical devices.

What Are the Applications of 3D Printing in Healthcare?

Listed below are several key applications of 3D printing in healthcare:

- Customized spinal and orthopedic implants.

- Customized prosthetic limbs.

- Specialized surgical tools and guides for exacting procedures.

- Highly detailed anatomical models based on patient-specific imaging data.

- Dental crowns, bridges, and orthodontic devices.

- Customized drug formulations and drug delivery devices, such as inhalers, patches, and implants, that are tailored to individual patient needs.

- Custom sockets used in prosthetic limbs.

- Patient-specific implants for craniofacial reconstruction

- Custom-fit hearing aids

- Patient-matched instruments used during surgeries

What Type of 3D Printer is Commonly Used for Healthcare?

Several types of 3D printers are used in healthcare settings, each with its unique advantages and drawbacks. Here's an overview of some popular 3D printing technologies in the medical field:

- Stereolithography (SLA): SLA 3D printers employ lasers to solidify liquid resins. They offer exceptional resolution, precision, and a range of printable materials. While SLA provides high-resolution and smooth surface finishes for anatomical models and medical prototypes, it does require post-processing steps.

- Selective Laser Sintering (SLS): SLS 3D printers use a high-powered laser to fuse polymer powder. This is ideal for complex mechanical parts with intricate designs and a requirement for excellent mechanical properties. Some SLS nylon materials are biocompatible, but their initial cost is higher compared to some other 3D printing technologies or materials used in healthcare applications.

- Fused Deposition Modeling (FDM): FDM melts and deposits thermoplastic filament layer by layer, offering cost-effectiveness but lower resolution. It suits basic prototypes and simpler parts but may require labor-intensive finishing.

- Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM): These techniques use lasers to melt metal powder particles layer by layer, crafting strong, biocompatible components, such as custom implants. However, they are costly and involve complex workflows.

- Bioprinting: Bioprinting integrates living cells and biomaterials to create organ-like structures supporting cell proliferation. While promising for various medical and tissue engineering applications, it introduces complexities related to material selection, and cell types.

To learn more, see our guide on 3D Printing Types.

What 3D Printing Materials Are Commonly Used for Healthcare?

In the healthcare sector, materials used in 3D printing must meet stringent criteria to ensure safety and effectiveness. These materials need to be sterilizable, biocompatible, corrosion-resistant, strong, durable, and lightweight. Fortunately, there are several commonly used 3D printing materials that fulfill these requirements, including:

- Nylon PA-12

- PC-ISO

- ABS M30i

- Titanium

- Cobalt chrome

- Stainless steel

- Thermoplastic polyurethane (TPU)

- Polylactic acid (PLA)

- Polyetheretherketone (PEEK)

- Polyetherketoneketone (PEKK)

- Polymethyl methacrylate (PMMA)

- Bioceramics

- Polyethylene Glycol (PEG)

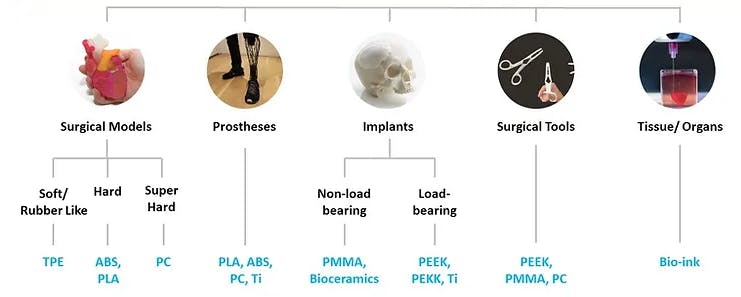

Figure 2 and 3 below are two flowcharts designed to assist you in the selection of the ideal material for your specific needs:

3D medical printing material selection flow chart based on application.

Image Credit: https://www.novusls.com/post/medical-3d-printing-material-selection-guide

3D medical printing material selection flow chart based on material functionality.

Image Credit: https://www.novusls.com/post/medical-3d-printing-material-selection-guide

What Are Other Real World Applications of 3D Printing?

There are many other commercial applications of 3D printing beyond medicine and healthcare, including:

- Aerospace: 3D printing is used to produce lightweight, high-strength components for aerospace applications, including rocket engines and satellite parts.

- Automotive: Car manufacturers use 3D printing to produce prototypes, customized parts, and even entire vehicles. Vehicle components can be 3D printed and assembled, this includes engine components, interior design components, etc.

- Architecture: Architects use 3D printing to create scale models of buildings and urban environments, allowing for more accurate and detailed planning.

- Education: 3D printing is used in educational settings to teach students about engineering, design, and manufacturing, and to allow them to create their own designs.

- Jewelry: 3D printing is used to create custom jewelry designs with intricate details and unique shapes.

- Art: 3D printing is used in the creation of sculptures, installations, and other forms of art, allowing artists to experiment with new materials and shapes.

For more information, see our guide on the 10 Applications and Examples of 3D Printing Uses.

What Are the Challenges of Using 3D Printing for Medicine and Healthcare?

The main challenges for FDA oversight of 3D printing in the medical industry are related to the decentralized manufacturing of customized medical products using 3D printing technology. Organizations or individuals who might have limited experience with following FDA regulations can manufacture implantable medical devices or other medical products using 3D printing. When 3D printing is used in centralized facilities by registered manufacturers subject to FDA inspection, oversight responsibility is clear. However, oversight becomes less clear when 3D-printed medical products are manufactured at the point of care.

The FDA is responsible for ensuring that manufacturers comply with good manufacturing practices and that the products they create meet the statutory requirements for safety and effectiveness. The agency needs to adapt regulatory requirements to ensure that 3D-printed medical products are fit for their intended use and safe for patients.

It is also important to note that the actual practice of medicine is primarily overseen by medical boards, rather than the FDA. However, in certain clinical scenarios which use 3D printing, it may not always be easy to distinguish between the product and the practice of medicine.

How Safe Is 3D Printing Technology for Medicine and Healthcare?

The safety of 3D printing technology in medicine and healthcare depends on a number of factors, including: the materials used, the design of the product, and the production process. In general, 3D printing technology is considered safe when used appropriately and in accordance with established guidelines and standards. For example, medical devices produced through 3D printing must meet the same safety and efficacy standards as those produced through traditional manufacturing methods. However, there are some potential safety concerns associated with 3D printing in medicine and healthcare. For example, there is a risk of contamination if the printing process is not properly controlled or if the materials used are not sterile. There is also a risk of mechanical failure if the product is not designed and produced correctly.

To address these concerns, regulatory agencies such as the FDA have established guidelines and standards for the design, production, and testing of 3D-printed medical devices. Healthcare providers and manufacturers must follow these guidelines to ensure the safety and efficacy of their products.

Why Is 3D Printing the Future of Medicine?

3D printing is widely regarded as the future of medicine due to its transformative potential in healthcare. Firstly, it enables the creation of personalized medical devices and prosthetics tailored to individual anatomy. This improves patient outcomes and comfort. Secondly, 3D printing excels in replicating intricate anatomical structures. It facilitates surgical planning, education, and medical procedure refinement. Thirdly, rapid prototyping also accelerates the development of medical technologies, reducing time-to-market for innovations. The on-demand production capabilities of 3D printing in hospitals streamline patient care and cost-efficiency by eliminating large inventories and lengthy lead times. Though initial investment may be high, long-term savings result from reduced need for revision surgeries with customized implants. Finally, 3D printing aids remote healthcare, producing medical devices in underserved areas and expanding access to services. Continual innovation in medicine, from drug delivery systems to wearable devices, is also fostered by 3D printing technology.

Can 3D Printer Products Be Used in Surgery?

Yes, 3D printer products have gained popularity for use in surgical procedures in a number of medical specialties. They enable the creation of patient-specific anatomical models, surgical guides, and implants, enhancing surgical precision and planning. Surgeons also benefit from customized tools, improving efficiency. Furthermore, 3D-printed models serve as valuable educational aids, enhancing surgical training. In specific fields, such as otolaryngology, temporal bone models aid in ear surgery practice. 3D printing is pivotal in oral and maxillofacial surgery for dental implants and prosthetics tailored to patients' anatomies. Additionally, it contributes to prosthetic limb development and surgical training.

Is 3D Printing Now a Common Practice in the Medical Field?

Yes, 3D printing has become increasingly common in the medical field. It is being widely adopted for various applications, including anatomical modeling, surgical planning, the creation of custom implants and prosthetics, and even drug delivery systems. Many hospitals and medical institutions have integrated 3D printing into their practices to improve patient care, surgical outcomes, and medical device development. While its adoption may vary by region and institution, the overall trend is toward increased use of 3D printing in medicine due to its numerous advantages and potential for innovation.

Do Medicine and Healthcare Benefit From 3D Printing Technology?

Yes, medicine and healthcare greatly benefit from 3D printing technology. The medical industry has been one of the early adopters of 3D printing technology, and the benefits are numerous. The ability to create customized and patient-specific medical devices, prosthetics, implants, and models with 3D printing technology has revolutionized the way healthcare providers approach patient care. This technology has enabled faster production, reduced costs, and improved patient outcomes.

Moreover, 3D printing technology has allowed for greater accuracy in surgical planning and improved medical education. 3D-printed models of patient anatomy can be used to plan surgical procedures, and medical students and residents can learn about anatomy, surgical procedures, and medical devices through the use of 3D-printed models. 3D printing technology has also facilitated the development of new and innovative medical devices and products, and it has allowed for greater accessibility to medical devices and prosthetics, especially in remote or low-income areas.

Are 3D-Printed Limbs Strong Enough?

Yes, 3D-printed artificial limbs can be strong and durable. Their strength depends on several factors such as the materials used, the design of the limb, and the intended use of the limb. With advancements in 3D printing technology and materials, it is now possible to create prosthetics and orthotics that are just as strong and durable as conventionally manufactured ones. For example, 3D-printed prosthetics can be made using materials such as titanium or carbon fiber, which are known for their strength and durability.

Are the Materials Used by 3D Printers Safe for Medical Use?

No, not all materials used by 3D printers are safe for medical use. However, there are a number of materials that have been approved for use in medical applications. For example, biocompatible materials such as medical-grade titanium and cobalt-chromium alloys are used in the production of implants and other medical devices. There are also biocompatible polymers like polyethylene terephthalate glycol (PETG) and polylactic acid (PLA) that are commonly used in the production of medical devices, prosthetics, and orthotics.

It is important to note that the safety of materials used in 3D printing depends on several factors beyond their chemical composition, such as the intended use of the product, the type of printer, the printing process, and the quality of the materials. Materials that are not properly tested or approved for medical use can potentially cause harm to patients.

Summary

This article presented 3D printing in medicine, explained it, and discussed its various applications. To learn more about 3D printing in medicine, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notice

- M3DIMAKERTM is owned by FabRx Ltd., a pharmaceutical biotechnology spin-out from University College London (UCL)

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.