Several exciting prospects are on the horizon for 3D printing developments. Researchers are continually exploring novel materials and processing methods for 3D printing. 3D printing is increasingly being integrated with other sunrise technologies: artificial intelligence (AI), robotics, and virtual reality (VR). These linkages deliver increasingly effective automated manufacturing processes, rapid design optimization, and more-informative prototyping experiences. This family of technologies is central to the development and refinement of Industry 4.0.

The adoption of the more advanced and more accessible forms of custom 3D printing continues, growing across diverse fields. As the technology becomes more accessible and versatile, its applications will expand into more productization and human-endeavor areas.

This article will delve into eight possible futures of 3D printing.

1. 3D Printed Homes

3D-printed homes represent a nearly groundbreaking innovation in construction, offering a promising solution to rapid and digital building. This is performed by large-footprint 3D printers operating in a concrete material version of fused filament fabrication (FFF), delivering rapid and low-labor construction.

In principle, 3D-printed homes will become more affordable than conventionally built homes, as technology advances. The reduced labor requirement lowers construction costs, making it an attractive option for affordable housing initiatives, standardized and flexibly customized buildings, and rapid-response construction in disaster areas.

Digitally manufactured homes also have the potential to be more sustainable. The minimization of waste and the use of eco-friendly construction materials, even using primarily recycled materials, can greatly reduce the environmental impact of construction.

2. Construction Industry

Beyond abodes, 3D printing holds immense potential for innovation in the construction industry across a much wider spectrum of applications.

3D printing can be expected, eventually, to fabricate infrastructure such as bridges, tunnel linings, and dams. Architects and designers can leverage 3D printing to create intricate and customized architectural features, including facades, ornamentation, and sculptures. The loss of obvious artistry in construction is noted, as cost-saving has defined these features as luxury. 3D printing is likely to free designers from some of these style restrictions.

3D printing enables the fabrication of modular building components, in an off-site kits-set manufacturing process. On-site assembly allows streamlining of the manufacturer/construction process, improving precision and quality control. 3D printing can be used to create urban-facility components such as benches, planters, streetlights, decorative paving, and retaining walls. Customized features enhance public spaces and improve the aesthetic and functional design of human environments.

The same techniques in development now are likely to become keystones in the longer term in the commercial exploitation of the lunar surface in mineral and Helium-3 extraction.

3. Metal 3D Printing

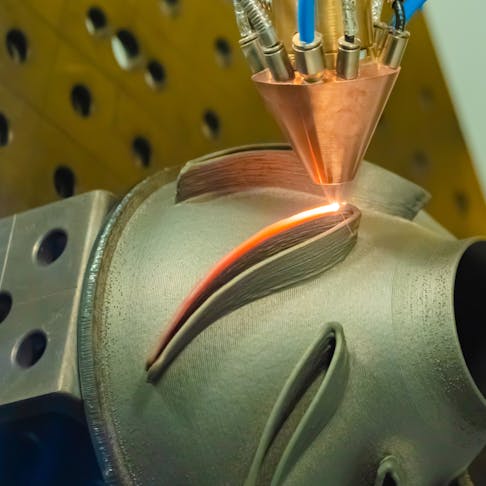

Research is burgeoning in the range of metal alloys that can be 3D printed. Efforts are being made to optimize existing metal powders for specific applications and to reduce costs and handling difficulties/hazards. The refining of process parameters and optimization of printing conditions deliver higher precision, improved surface quality, and greater dimensional accuracy. This is partly driven by enhancements and step-changes in laser and electron beam technology, and more esoteric advances in powder bed fusion and directed energy deposition techniques. Steady improvements in the speed and productivity of metal 3D printing processes include the development of faster core technologies like multi-laser systems and high-speed powder deposition processes. Less glamorous but equally important are improvements in build chamber design and heat management to reduce print times, improve energy consumption, and increase productivity.

Metal 3D printing is increasingly being adopted for increased volume and part sizes in the production of complex parts and components such as combustion chambers. Evolving equipment and techniques are increasing reliability in large-scale manufacturing operations. NASA, DARPA, and military field maintenance are all driving these developments at a high and increasing pace. Post-processing is a critical aspect of metal 3D printing, and advancements in integration with surface finish, heat treatment, and precision machining of 3D-printed metal parts are necessarily and rapidly developing. This serves to simplify workflows and deliver more finished components with less handling, simpler logistics, and better repeatability.

4. Manufacturing Sector

3D printing will play an increasingly crucial role in advancing sustainability initiatives within the manufacturing sector. More efficient use of materials and support of circular economy principles are expected to result from 3D printing technology penetration into general manufacturing.

Metal 3D printing is in increasingly widespread adoption across the most demanding manufacturing sectors. With developing maturity and improving cost-effectiveness, manufacturers will inevitably adopt it more widely. Developments in 3D printing are enabling the printing of multiple materials within a single build process. This can be expected to increase steadily. This allows for hands-free fabrication of increasingly complex parts and finished products with graded materials/properties.

3D printing continues to be central to Industry 4.0 development. This facilitates automated process monitoring, real-time QC, and automated workflows in manufacturing operations. Developments in material science are resulting in the introduction of new materials for 3D printing: polymers, metals, ceramics, and composites of these and reinforcers. These materials allow the fabrication of parts for a broader range of applications.

3D printing technology is increasingly enabling the decentralization of manufacturing through on-demand production and distributed manufacturing. It will become increasingly practical for companies to be able to produce parts closer to the point of use, for lower operational overheads.

5. Material Innovations

Material innovations in the 3D printing sector are driving significant advances in scope, applicability, and cost, ramping up the capabilities of additive manufacturing technology.

R&D focused on developing advanced polymer materials with enhanced mechanical properties, chemical resistance, and thermal stability is ongoing and accelerating. More commonly printed by FDM®, improving powder bed methods are allowing a wider variety of outcomes/applications and higher resolutions, approaching molded-part properties. Innovations in metal additive manufacturing materials are resulting in new metal alloys with improved strength, durability, and corrosion resistance. The nature of 3D printing is unlike melt processing, so it allows graded alloys (transitioning between metals through a build) and high-entropy alloys (HEAs, percentage fixtures that cannot form a solution in melt processing) to be used.

Ceramic and composite materials are playing an increasing role in 3D printing, thanks to advancements in material science and processing techniques. This holds out the potential for unique properties such as high-temperature resistance, extreme durability/toughness, anisotropic electrical insulation/conduction, and biocompatibility. In bioprinting, researchers are developing bioinks and biomaterials, direct-cellular printing, and growth framework approaches capable of replicating patient-native tissues and organs. Personalized medical implants, tissue-engineered constructs, replicated organs, and drug delivery systems are all likely near-term developments.

Future material innovations are going to include smart and functional materials with embedded sensors, actuators, and responsive properties typified in 4D printing. This enables the fabrication of smart devices, wearable electronics, and intrinsically functional prototypes.

6. Aerospace Applications

3D printing in the aviation, drone, and orbital sectors is on the cusp of significant growth and innovation.

3D printing localizes and simplifies the fabrication of otherwise impractically complex, lightweight structural components with optimized geometries. These can help reduce weight without sacrificing resilience for improved fuel efficiency. The technologies are revolutionizing the production of engine components such as turbine blades, fuel nozzles, and combustion chambers. The creation of otherwise non-manufacturable internal features enhances performance significantly.

3D printing technologies are being used to produce components for satellites, spacecraft, and launch vehicles. Orbital manufacture (i.e., outside the Earth’s atmosphere) on-demand will reduce the need for launches — a key need in expected longer-duration missions. Aerospace and military companies achieve greater supply-chain resilience by enabling localized production of highly advanced spare parts and components, minimizing potential supply-chain disruptions.

7. Organ Engineering

Developments in direct and indirect organ engineering via 3D printing approaches offer immense promise for regenerative medicine.

Research into developing bioinks and biomaterials that mimic the extracellular matrix (ECM, scaffold materials) of human tissues is advancing. These create an implantable environment for patient cell growth and differentiation, enabling the population of the scaffold with patient-functional tissues. Bioprinting techniques allow for the deposition of living cells in three-dimensional matrices to create functional tissue structures. The complex architecture and functionality of native tissues and organs are beginning to be developed. This is a rapidly expanding research area.

A major challenge in bioprinting is the incorporation of vascular networks to sustain printed tissues. Researchers are developing strategies to bioprint intermediary structures to promote angiogenesis and vascularization. Research into this is early but promising and liable to develop rapidly.

Bioprinting is merging with microfluidics to create organ-on-a-chip as miniaturized models of human organs for drug testing and disease modeling. These offer the prospect of better predictive models for drug development and personalized medicine. This shortens the time-to-market burden of drug development. The bioprinting of entire functional organs (hearts, kidneys, livers, lungs) for transplantation is in the experimental stage. Significant progress in creating organoids and tissue constructs is happening among academic networks.

As bioprinting technologies proliferate, efforts toward regulatory approval for bioprinted products are progressing in sync. A few bioprinted products have already received regulatory clearance for clinical trials.

8. Advancements in Healthcare

Predicted and envisioned advances in healthcare from 3D printing populate a spectrum of applications that will have transformative effects on patient care, medical procedures, and biomedical research.

Patient-specific implants and prostheses made by 3D printing provide custom-designed aids and orthotics tuned to an individual patient’s anatomy. This perfects fit, enhances function and comfort, and leads to better treatment outcomes and quality of life. Surgeons are increasingly using 3D-printed anatomical models, derived from CAT-scan data to visualize patient anatomy and plan complex procedures. These unique models improve planning/learning, enhance accuracy, reduce surgery time, and generally improve patient outcomes.

Bioprinting technology is beginning to allow the fabrication of functional tissues and organs using patient-derived living cells. These can aid in drug screening, disease modeling, and regenerative medicine applications. 3D printing serves in the fabrication of drug delivery systems, such as personalized medication doses, controlled-release formulations, and implantable drug-eluting devices. Point-of-care manufacturing of medical devices, instruments, and equipment can reduce reliance on centralized manufacturing facilities and supply chains.

Advances in 3D bioprinting technology are driving research in regenerative medicine, such as: engineered functional tissues, organoids, and bioactive scaffolds for tissue repair and patient cell colonization to treat degenerative diseases, traumatic injuries, and congenital defects. Dental and maxillofacial applications are already in wide use and expanding in capability and market penetration. Fabricating dental prostheses, orthodontic appliances, and surgical guides is commonplace and growing in capability rapidly.

To learn more, see our article on Advancement in Healthcare.

Types of Materials Being Experimented With in 3D Printing

Some types of materials being experimented with in 3D printing are:

- Advanced polymer materials such as PEEK (polyetheretherketone), PEKK (polyetherketoneketone), ULTEM® (polyetherimide) and PPSU (polyphenylsulfone).

- Metal matrix composites (MMCs) such as ceramic fibers/powders, graphene, or carbon fibers for elevated strength, stiffness and wear resistance.

- Functional materials such as conductive inks, electrostrictive and electroactive polymers, diamagnetic and paramagnetic materials, or self-healing polymers.

- Nanoparticles, nanotubes, and nanofibers that offer unique properties like enhanced strength, conductivity, and thermal stability. Their incorporation into 3D printing formulations results in advanced nanocomposites with various planned and unexpected benefits.

Copyright and Trademark Notices

- FDM® is a registered trademark of Stratasys Inc.

- Ultem® is a registered trademark of SABIC Innovative Plastics IP BV (formerly GE Plastics)

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.